Since November 28, 2017, China’s new amorphous and nanocrystalline soft-magnetic alloys and components motor core material manufacturer ZKNB developed a high-performance energy-saving motor core material that has been applied to ultra-high-speed and high-efficiency motors with more than 90,000 rpm.

ZKNB was established in September 2005, a new material technology-based enterprise led by a full-time young doctor team from the Top Institute of Alloy Materials, Focus on R & D, production and sales of high-performance energy-saving soft magnetic alloys and power electronic devices.

They developed the world’s top energy-saving iron core material, and took the core technology of high-speed motors in their own hands.

What is this core technology?

“Citizens who have filled their teeth must have experienced the fear of opening their mouths and letting the drill bit buzz on their teeth. If a higher speed motor is installed on the dental drill, its accuracy will be greatly improved and shortened as the speed increases. The operation time will reduce the pain for the patients. “Dr. Huo Lishan introduced a miniature electric dental drill. The new energy-saving core material developed-sub-nano alloy, is the key to manufacturing high-speed motors.

Sub-nano alloy is a new type of amorphous nano-crystalline alloy with unique microstructure, which has become an irreplaceable high-end iron core material in the field of high-precision devices. As the main magnetic circuit part of the transformer, the iron core is an indispensable part of the motor. “The iron core made of the new sub-nano alloy is installed on the motor, which greatly saves electrical energy and improves the output power.” Guo Hai, chairman of ZKNB, said that the advantages of the new products are more obvious in high-speed motors. At present, ZKNB’s sub-nano alloy has been successfully applied to high-speed motors of 60,000 rpm and 90,000 rpm, which reverses the situation of relying on imported materials. High-speed motors with more than 150,000 rpm are under development.

At present, the amorphous nanocrystalline alloy widely used in domestic and foreign markets is developed in Japan, and its saturation magnetic induction intensity is low, and it is still difficult to replace traditional silicon steel materials in application. The sub-nano alloy launched by ZKNB fills the domestic technological gap, and its saturation magnetic induction intensity is higher than that of the latest generation of amorphous alloys in Japan.

“Although the sub-nano alloys are very small, the market capacity is huge.” Dr. Huo Lishan said that from small electric drills to aerospace equipment, high-precision machine tools, and electric vehicles, high-speed motors are needed.

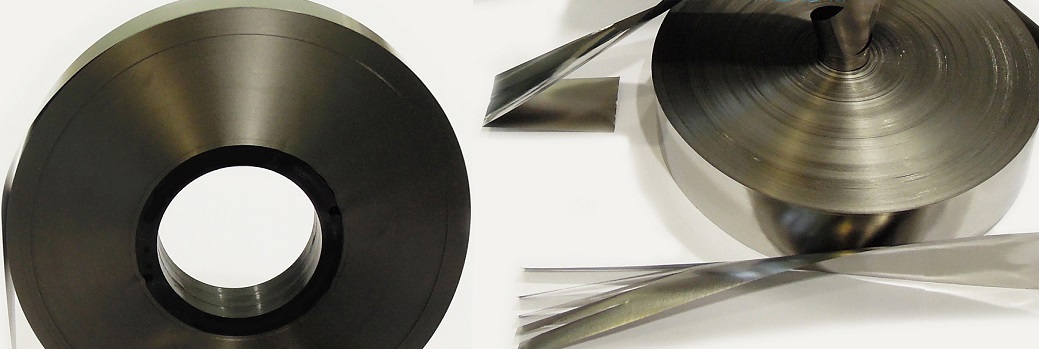

Sub-nano alloy and amorphous nano-crystalline alloy

It is a new kind of energy-saving soft magnetic material with both high saturation magnetic flux density (Bs) and low core loss.

Its saturation magnetic flux density reaches above 1.7 T, significantly higher than the traditional amorphous alloy (1.56 T).

Application Area:

The amorphous nanocrystalline alloy Ribbons can be used to make the high quality magnetic cores of the electric power & electronic devices, such as the high-efficient motors, distribution transformers, reactors, current transformers, inductors, inverters, switch power transformers, etc. Significant miniaturization and energy -saving effect can be achieved in the devices by using the ribbons.

As the excellent soft-magnetic material, the ribbons can also be applied to the security labels, electromagnetic shielding and wireless charging of the electronic products, etc.