consulting & Solutions

Hay Think has the insight, expertise and tools to create and implement effective strategies that deliver value-creation and sustainable competitive advantage results

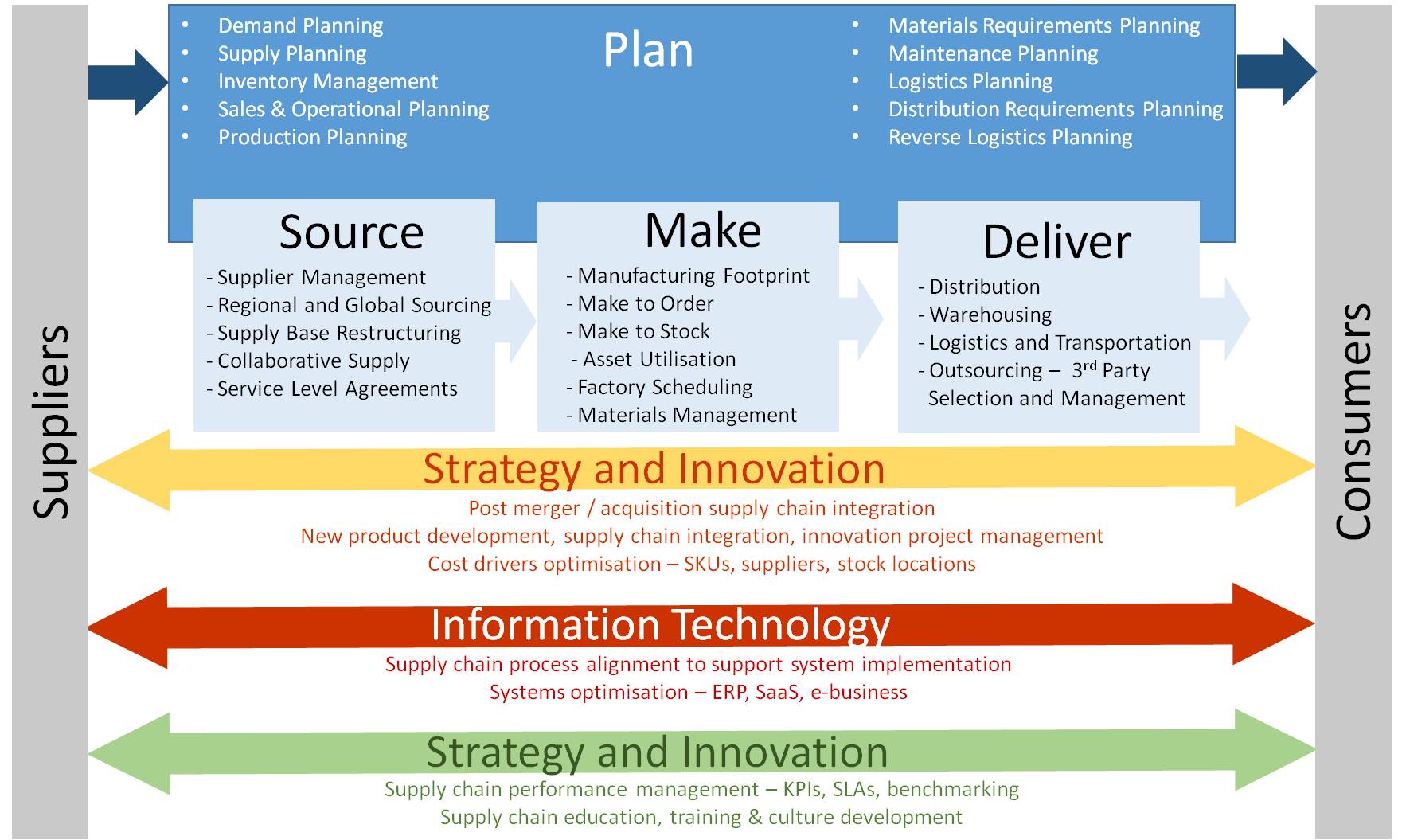

Supply Chain Management

Supply Chain Planning Management

SCP:SUPPLY CHAIN PLANNING

MMOG/LE Supply Chain Maturity Evaluation System

Hay Think will evaluate the supply chain management system of customer companies based on the MMOG / LE-based supply chain maturity evaluation system, and provide targeted supply chain management solutions based on the results of the evaluation.

Supply chain planning is the core of supply chain management, which includes two levels of long-term planning and short-term planning of the supply chain:

The medium and long-term planning of the supply chain includes

Supply chain organization planning and team capacity planning

Supply chain performance evaluation system planning

Analysis of supply chain cost driving factors and cost reduction planning

Available capacity planning

PFEP

Strategic Supply Chain Network Design and Planning

Layout planning and design of logistics center

Supply chain business process planning and reengineering

Logistics Information Planning and Implementation

Planning and implementation of logistics automation system

Optimization of inventory strategy

Warehousing planning

Packaging planning

…

The short-term supply chain plan includes

Demand Management and Demand Planning

S & OP Sales and Operations Planning

Collaborative planning [forecasting and supplementation]

[PMC Production Material Control / Production Material Control [PC Production Control and MC Material Control System]]

MPS Master Production Planning

RCCP Rough-Cut Capability Planning

MRP

CRP Capacity requirements planning

PAC production operations and scheduling

FAS Final Assembly scheduling

Inventory planning

…

Prepare for the unexpected with more accurate planning and forecasting

Supply chain planners are under constant pressure to reduce costs, increase efficiency and increase profitability. Unfortunately, too many of them lack visibility into the data and rely on manual planning tools. Solutions used by best-in-class organizations can adjust plans as needed and leverage deep insights to understand business drivers. This helps demand and supply chain professionals create smooth, synchronized and responsive supply chain plans.

Industry Insights: Maximizing Supply Chain Efficiency

Aberdeen’s research results show that companies with superior supply chain management are almost 30% more likely than regular companies to have analytical, standardized processes for execution planning and forecasting. Using this model to continuously evaluate and respond to market changes is a significant difference between the state of chaotic supply chain management and the state of supply chain operations.

Driving a more dynamic and responsive supply chain

A single source of fact is essential for accurate planning. This principle runs through the entire organization-sales, finance, marketing, operations and the entire supply chain. Working in silos can only lead to inefficiencies and errors.

Analyze historical data to help demand planners identify trends, spot discrepancies and plan performance

Demand planners must have access to all historical data to be able to identify trends, spot discrepancies, and make reasonable demand forecasts. By developing a consensus plan, demand planners can avoid mismatched data across multiple spreadsheets, and can make effective adjustments to demand plans in unexpected situations or changing consumer preferences.

Monitor supply chains in real time to help supply planners create accurate supply forecasts

Supply planners need to know what’s going on in the supply chain in real time so they can create accurate supply forecasts. To avoid the loss of revenue caused by shortages and stockouts, you must be able to run what-if scenarios and ensure they make the most informed decisions.

Use data visualization, flexible planning and what-if scenarios to help SOP planning managers make better business decisions

Sales and operations planning [S & OP] managers need a single version of the fact to make better business decisions and achieve revenue goals. Easy-to-use data visualization, flexible planning to adapt to market needs, and fast, what-if scenario assessments are critical.

Hay Think plan analysis: the key to your efficient supply chain planning, optimization and efficiency

Eliminate data silos

Eliminate data silos with integrated solutions

Eliminate your data silos with integrated planning solutions, making supply chain contribution and collaboration a daily practice. Develop a consensus needs plan for broad support.

Save time and guarantee accuracy

Save time by automating data collection in a custom workspace provided in a customizable Microsoft Excel interface. Ensure accuracy and a version of the fact.

Turn large amounts of data into visual reports

Easily analyze and process large amounts of data into simple charts. Collect insights directly from your data and create more timely and reliable plans and forecasts.

Test plan and update plan dynamically

Test an unlimited number of complex scenarios to determine the best course of action. Understand the impact of potential results and dynamically update plans to suit market conditions.