China leading Carbon-Matrix composite materials: crystalline silicon, vacuum heat treatment metallurgy high-temperature HNJB Carbon Matrix Composites Tech Corporation. plans to expand the capacity expansion and R & D center project of advanced carbon-based composite materials. The total investment is estimated to be about 292 million yuan, of which the carbon-based capacity expansion project is 229 million yuan. R & D center project 62.2 million yuan. The construction period is expected to be 2 years.

① The carbon-based capacity expansion project intends to increase Jinbo’s carbon-based capacity by purchasing approximately 75 acres of planned construction land, constructing production plants and supporting facilities, and purchasing equipment. After the project is completed, it is estimated that the new advanced carbon-based composite material production capacity will be 200 tons / year.

②The location of the carbon-based R & D center project is the same as the advanced carbon-based composite material capacity expansion project. The R & D center and laboratory are built in the planned plant and office building. Talents etc. enhance HNJB’s R & D and innovation capabilities.

About HNJB Carbon Matrix Composites Tech Corporation.

HNJB Carbon Matrix Composites Tech Corporation. was established in June 2005. The company is mainly engaged in the research, development, production and sales of advanced carbon-based composite materials and products. It is a national high-tech enterprise with independent research and development capabilities and continuous innovation capabilities. . The company is committed to providing customers with advanced performance and cost-effective advanced carbon-based composite materials products and a full set of solutions.

The company has a new material innovation talent team covering materials, textiles, non-wovens, machinery, electrical and other disciplines. It has undertaken major scientific research projects such as the National 863 Plan, the Ministry of Science and Technology Innovation Fund Project, and the Development and Reform Commission High-Tech Industrialization Special Project. “Hunan Provincial Engineering Research Center for Low-cost Carbon / Carbon Composite Preparation Technology”. The company is a national intellectual property superior enterprise; as the first drafting unit, it has formulated 5 national industry standards. The company has won 1 first prize for scientific and technological progress in Hunan Province and 3 second prize for patents in Hunan province.

Relying on independent research and development and continuous innovation, the company has made major breakthroughs in low-cost production and production of advanced carbon-based composite materials, diversified product varieties, and independent design of equipment. It has mastered the core technology of low-cost production of advanced carbon-based composite materials and achieved Mass industrialization. The products have been promoted and applied in the crystalline silicon manufacturing thermal field system, and the import substitution and upgrade of high-purity isostatic graphite products have been successfully implemented, and the overall technology is at the leading level in the industry.

In the future, the company will continue to increase technological innovation, leverage the company’s research and development advantages and leading advantages in the field of carbon-based composite materials, carry out related diversified product development and market expansion, and research and development for high temperature, wear resistance, corrosion resistance and other fields Products, extending and expanding the field of carbon-based composite materials, making the company an advanced carbon-based composite material research and development and industrialization application platform, and becoming a globally competitive advanced carbon-based composite material manufacturer and supplier.

Carbon Composite Materials Technologies

Carbon / Carbon Composite Materials (Carbon / Carbon Composite Materials) is a composite material of carbon fiber and its fabric-reinforced carbon matrix. It was first discovered by the United States CHANCE VOUGHT laboratory in 1958. New advanced materials. It has the following advantages: (1) The entire system is composed of carbon elements. Because carbon atoms have strong affinity with each other, they have good stability at low or high temperatures. At the same time, the essential properties of the high melting point of the carbon material give the material excellent heat resistance and can be used for a long time in a protective atmosphere at 2500 ° C. (2) Excellent high temperature mechanical properties, it is currently the best material for high temperature mechanical properties in an inert atmosphere. More importantly, the strength of this material does not decrease with increasing temperature, even higher than at room temperature, which is unmatched by other structural materials. (3) Light specific gravity (less than 2.0g / cm3), which is only 1/4 of the nickel-based superalloy and 1/2 of the ceramic material. (4) Good anti-ablation performance, uniform ablation, can withstand high temperature higher than 3000 ℃, used in short-term ablation environment. (5) Excellent friction and wear resistance, it is the best candidate material for various wear and friction parts.

Carbon / ceramic composite materials refer to a new type of composite materials with carbon fiber as the reinforcement and silicon carbide as the continuous matrix. Carbon / ceramic composite materials not only have the advantages of high strength, high modulus, high hardness, impact resistance, oxidation resistance, high temperature resistance, acid and alkali resistance, small thermal expansion coefficient, light weight, etc. of high performance ceramics, but also overcome general ceramic materials Its shortcomings such as high brittleness and single function are recognized as one of the ideal high temperature structural materials and friction materials.

Products

Single-Crystal Pulling Furnace Hot Zone

Crucible

Reflector

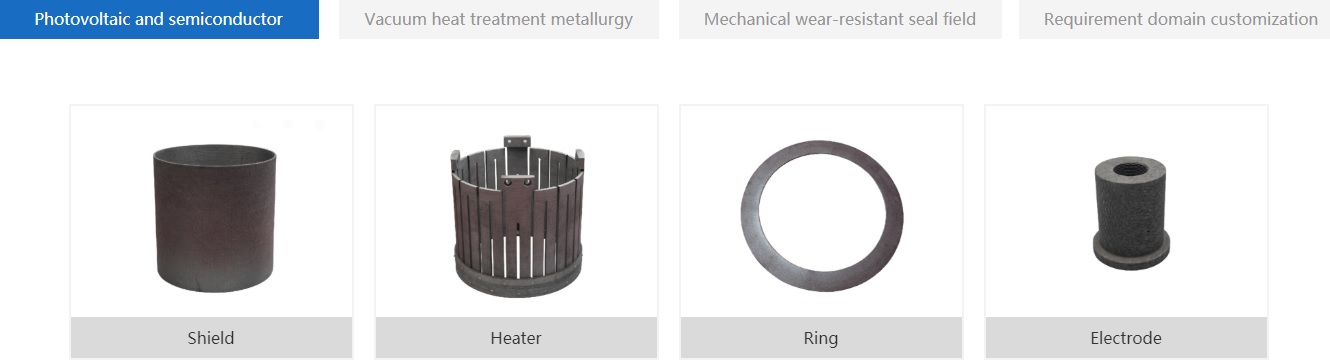

Shield

Heater

Applications

Photovoltaics Field

Top Plate,Cover Plate,Heater,Support Plate,Fasteners,Heat Shield,Crucible,Reflector,Shield,Heater,Ring,Electrode

Semiconductor Field

MOCVD Disk

Single-Crystal Hot-Zone

Vacuum Heat Treatment Field

Products For Mechanical Engineering

High Temperature & Pressure Forming Field

Mould Sleeve,Mould Frame