WXFE Additive Manufacturing Technology Co., Ltd. is China's leading provider of complete solutions for metal additive manufacturing technologies. The company has three business divisions: special metal powder division, 3D printing solutions division, and special manufacturing technology division. Revenue in 2019 increased by 50.63% year-on-year, and it is expected that operating income will exceed 200 million yuan, mainly in 3D printing services.

Additive manufacturing is a rising industry, whether it is at home or abroad, it is accelerating the process of mass industrialization.

WXFE is an important manufacturer of high-quality aerospace components in China. Up to now, it has completed the processing and manufacturing of more than 30,000 components and has accumulated rich experience.

WXFE is one of the few additive manufacturing service providers in civil aviation in the world that has passed multiple audits. Among them, the domestic C919 has passed the airworthiness certification, and the metal 3D printed parts provided by WXFE have passed the airworthiness certification. In the field of aerospace, WXFE has also accumulated a lot, and has participated in the structural design and printing trial production of multiple types of additive manufacturing parts. In-depth cooperation in processing machine processing, performance testing, etc., some models have passed flight tests. "

WXFE has a complete chain of metal powder preparation-metal 3D printing parts manufacturing-metal 3D printing airworthiness certification. It has been actively working with designers to improve the structural optimization of products. 3D printing is an important means of realization. One of the typical cases is C919. We optimized the structure of a certain part. After 3D printing, the weight loss reached more than 30%, but the performance did not decline, and the overall cost dropped significantly.

The development of WXFE in recent years has basically doubled every year. The metal powder and metal 3D printing manufacturing services are rapidly expanding, especially as the domestic titanium alloy 3D printing powder material and 3D printing parts supplier designated by the C919 project , Feilkang is full of confidence:

• There are strict quality control standards for the quality of powder materials, 3D printing processes, and the entire production process. In the future, we will obtain more closed-loop and controllable product quality and better market prospects.

• In terms of 3D printing services, we will actively expand production capacity in 2019, and will continue to expand the production capacity of 3D printing equipment, including the investment of some large equipment and proprietary equipment, to provide sufficient production capacity guarantee.

• Continue to enhance customer service awareness and emphasize customer priority.

• Complete processing and manufacturing capabilities: enhance the overall process and manufacturing capabilities of metal powder-3D printing-hot isostatic pressing-heat treatment-machining-polishing, etc. In the quality control and rapid iteration of additive manufacturing, it occupies the industry's leading opportunity.

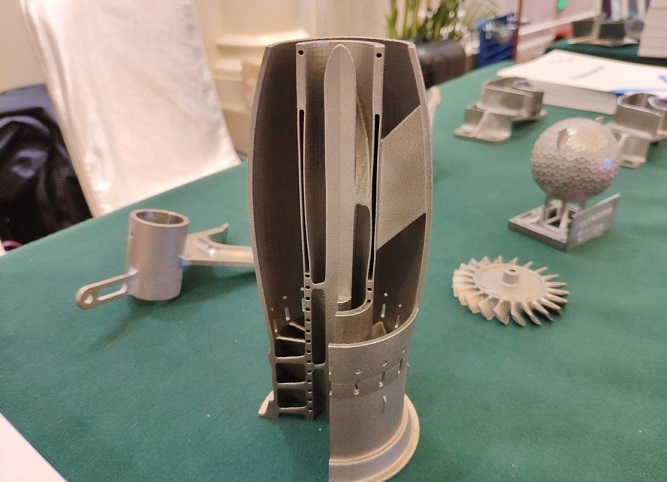

3D printed metal aviation structural parts

3D printed metal parts with optimized structure