Phase Change Material (PCM)

PCM refers to a class of energy storage materials that absorb or release a large amount of energy during phase transition to regulate temperature. According to the type of phase transition, it can be divided into solid-solid, solid-liquid, solid-gas and liquid-gas PCM.

GDMR Graphene Technology Corporation is a national high-tech enterprise dedicated to the application and development of low-dimensional nanomaterials such as graphene, and develops industrial layouts in thermal management, new energy, and functional composite materials around the graphene R&D matrix.

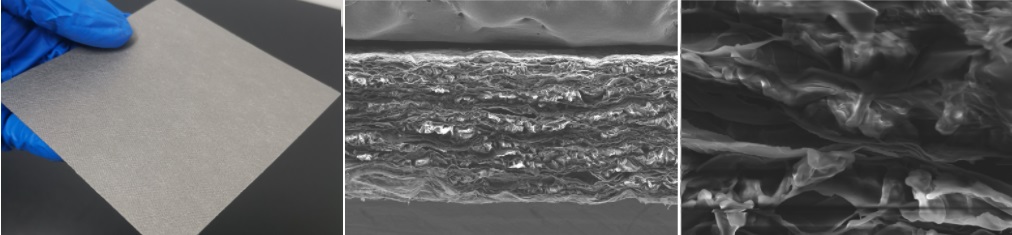

The GDMR R&D team pioneered the three-dimensional structure of graphene to obtain a graphene membrane with a unique micro-nano cavity structure, filled with traditional phase change materials such as paraffin, and developed a new composite phase change material—— Graphene micro-nano-cavity phase-change vapor chamber. The product ushered in the industry debut on January 28, 2022, and the market responded strongly.

Due to the unique micro-nano cavity in its structure and graphene's own high strength (tensile strength 130 GPa), good toughness and other characteristics, the phase change filler is well "locked" in the skeleton, even after repeated occurrences of During the phase change, the loss of filler and the damage of the skeleton can also be avoided to a great extent, and the stability of the product performance can be finally ensured.

Using micro-nano cavity structure design and solid-liquid dual-state phase change material filling, the heat absorption performance is 140% higher than that of traditional phase change materials, and the thermal conductivity is 300 times higher than that of traditional phase change materials. In this way, the purpose of suppressing the heat of the chip and continuing to stabilize the output is achieved.

At the same time, graphene is the material with the highest thermal conductivity (>5300 W/mK) currently known. In addition to providing a stable support framework for the phase change filler, its high thermal conductivity helps the heat source heat to be quickly and uniformly distributed. It is transferred to the micro-nano cavity structure of the product, so that the phase change filler in the structure undergoes phase change and efficient heat storage. The overall thermal response rate of the product is very fast, and finally a rapid cooling effect is achieved, thereby reducing the energy in application scenarios such as electronic products. Excessive waste or wastage.

GDMR has achieved large-scale mass production of various types of products with different thicknesses and phase transition temperatures, and the production process is stable. Customers can customize according to their own requirements. The product fundamentally solves the problems of insufficient thermal conductivity, liquid leakage, and shrinkage and rupture of the phase change material itself, and at the same time, the product has excellent performance and is practical.

Its enthalpy value is above 200J/g, the in-plane thermal conductivity is above 40W/(m·K), and the product has passed REACH, RoHS, halogen-free and other environmental protection testing certification.