Recently, in the sputtering target production base of FJAS Electronic Materials Technology Group, a leading manufacturer of sputtering targets, evaporation materials and coating accessories in China, a new intelligent production line for PVD coating materials will soon be installed. After the production line is put into production, the production capacity of the sputtering target will be expanded to an annual output of 1200 tons of flat-panel display sputtering target, and enter the era of intelligent manufacturing.

The main products of FJAS include ITO (indium tin oxide) targets, molybdenum targets, aluminum targets, copper targets, silicon targets, etc. Among them, "high-quality ITO target material for TFT-LCD" is the key basic material for LCD (liquid crystal display) and new generation displays (OLED, QLED, MicroLED, etc.).

FJAS has established a R&D center with top Chinese universities to achieve breakthroughs in many key ITO target technologies. It is from the “FJAS Expert Workstation” led by Dai Pinqiang, a professor at Fujian College of Engineering and director of Fujian Provincial Key Laboratory of New Materials Preparation and Forming Technology. This transformation of scientific research achievements has broken through foreign technical barriers and achieved the localization of high-quality targets, making FJAS a strategic partner of dozens of world-class industry giants such as BOE, Innolux, Lansi Technology, and Berne Optics. , And successfully landed on the A-share market in 2017; the project achievements won the first prize of 2018 provincial scientific and technological progress.

"ITO targets play a key role in the quality, production efficiency and yield of LCD panels, and their quality requirements are very high." Dai Pinqiang told reporters that before 2015, domestic ITO targets had insufficient purity and insufficient green body density. It seriously affects the transmittance, resistivity and uniformity of ITO film, and can only be used in low-end occasions such as solar film and low-precision touch screen.

At that time, domestic high-quality ITO targets basically relied on imports, and its core technology had long been monopolized by large companies in Japan, South Korea and other countries. "This is very disproportionate to the status of China's major LCD manufacturing country." Dai Pinqiang said that 80% of the indium ingots (raw materials for ITO targets) in the world are produced in China, and foreign companies import indium ingots from China to produce high-quality ITO targets. , And then export to China at high prices, China has no bargaining power and long delivery period.

FJAS, determined to independently develop and produce ITO targets, began to cooperate with the long-term cooperation with Fujian Institute of Engineering. In June 2012, "FJAS Expert Workstation" was approved and hired Professor Dai Pinqiang as the leading expert of the work station. He led a team of 9 experts in station construction and conducted R&D with 15 people in the technical team of the company.

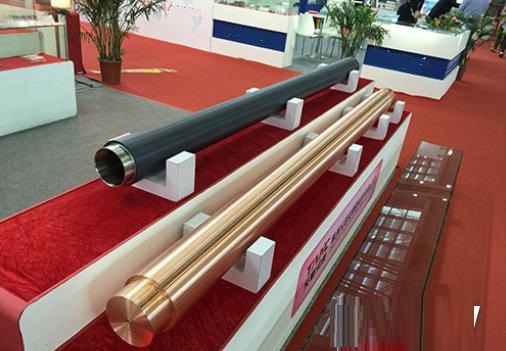

"To produce high-quality ITO targets, there are two key problems in front of us." Dai Pinqiang said, one is that the target consists of the target blank and the back plate, the target blank is ITO is oxide, the back plate is metal copper, the second The difference in thermal expansion coefficient is large, and it is easy to cause cracking of the target material and deformation of the copper backing plate during binding. The larger the size of the target, the more serious it is; At 4 to 5 microns, and the organization is uniform, the relative density is >99.7%, but the domestic technology and equipment at that time were difficult to produce such a high purity, high density and high uniformity target.

In response to these problems, the expert team of workstations began to carry out scientific research in 2012. After more than 4 years of unremitting efforts, the team has innovated and developed three key technologies such as high-purity nano powder preparation technology and powder homogenization, ITO target forming and sintering, and ITO target binding, which are key to high-quality ITO targets All-round breakthroughs have been made in core technology.

"For the bottleneck of target binding technology, we have realized the large-area continuous moving welding through the unique'ITO target stirring wire friction heating' technology, developed a new process of metal transition layer preparation, designed and manufactured related equipment, and reached high quality. The target's overall warping does not exceed the requirement of ± 2mm." Dai Pinqiang said, "For the purity, density, uniformity and other issues, we have adopted a new method of "multi-process coordinated control of powder performance", and proposed a high-purity nano powder preparation technology , Powder homogenization technology, research and development of related equipment, and research and development of high-density, low-moisture green body forming new technology, design and manufacture of target green body forming equipment, and development of oxygen-rich sintering key technology, effectively overcome Technical difficulties such as high temperature deoxidation and coarse grains during target sintering."

In 2016, the products using these new technologies and production equipment for trial production passed the strict import test verification of Fuzhou BOE Optoelectronics Technology Co., Ltd. The product's thin film particles, surface resistance, film thickness, transmittance and other performance indicators , Have reached the level of similar foreign advanced target materials, can completely replace imported products, successfully used in TFT-LCD production.

In 2017, high-quality ITO targets for TFT-LCD independently developed by FJAS were officially put into mass production. Since then, China has broken through the foreign technical barriers of large-scale high-end ITO targets, and has taken another step forward in the localization of important materials for the display panel industry.