The yoke forgings disc manufactured by SDYL Energy Equipment Tech Group, a large-scale disc, ring, cylinder, module forging and special-shaped forging manufacturer in China, are shipped to the world's largest pumped storage power station-Fengning Pumped Storage Power Station.

The yoke forging is an important structural part for fixing the magnetic pole and an important part of the entire magnetic circuit. It will be installed at the most core position of the generator motor unit. Due to the huge centrifugal force generated when the generator motor rotates, these centrifugal forces are mainly borne by the body of the yoke forging, so the quality requirements of the yoke forging are also very high. At -30 ℃, the tensile strength is ≥800MPa and the yield strength is ≥700MPa.

SDYL uses radial and axial integral rolling technology to manufacture yoke forgings, which breaks through the limitation of the opening space of traditional free forging presses on the size of forgings, improves the processing and installation accuracy of yoke components, and ensures good overall rigidity of yoke components. Successfully solved the problems of looseness and shrinkage of current cast steel yoke parts, deformation and wrong teeth of steel plate splice yoke parts.

Since 2019, SDYL has also provided various forgings such as ring plates, magnetic yoke discs, top cover flanges and other projects for Heilongjiang Huangou Pumped Storage Power Station and Guangdong Yangjiang Pumped Storage Power Station.

About Fengning Pumped Storage Power Station. The Fengning Pumped Storage Power Station is a key green energy project supporting the 2022 Beijing Winter Olympics and is used to provide power guarantee for various events during the Winter Olympics. After the project is completed, the annual power generation can reach 6.6 billion kWh, which is equivalent to saving 480,000 tons of standard coal, which is of great significance for achieving the 100% clean energy power supply promised by the Beijing Olympic Winter Games. After the completion of the first and second phases of the Fengning project, it will become the world's largest pumped storage power station with an installed capacity of 3,600 MW.

At present, the conversion rate of electric energy of large pumped storage power stations can reach an astonishing 75% -85%, while the conversion rate of our commonly used mobile phone charging treasure is only about 65%. Fengning Pumped Storage Power Station uses reversible generator motors (motors when pumping, which quickly become generators during power generation), and the pumping-generation state transition takes less than 5 minutes. When a large-scale power outage occurs in the power grid, the pumped storage power station does not need any external power, and only needs to "open the gate to release water" to instantly generate electricity and wake up the power grid. Fengning Pumped Storage Power Station will undertake the important tasks of peak shaving, valley filling and emergency response throughout the Beijing-Tianjin-Hebei power grid.

About SDYL Energy Equipment Tech Group

SDYL Energy Equipment Tech Group is a leading manufacturer specializes mainly in a diversified range of products within the forgings industry. Our main products include discs, rings, hollows and special-shaped forgings; grinding balls, rods and liners, mainly used in fields such as wind power, nuclear power, UHV, petrochemical, offshore engineering, machinery manufacturing, mining and other fields.

SDYL is in the leading position of clean energy, fossil energy, heavy equipment and mining industry including:

In the field of wind power, we are the main manufacturer of tower flanges in China, and provided tower flanges for DTC 10MW and GE 12MW;

Precision Forgings For Wind Turbine

Pipe Flange / Pylon Flange

Disc Forgings

Ring Forgings

Forged Hollows

Seamless Ring Rolling Forgings

Custom Forgings

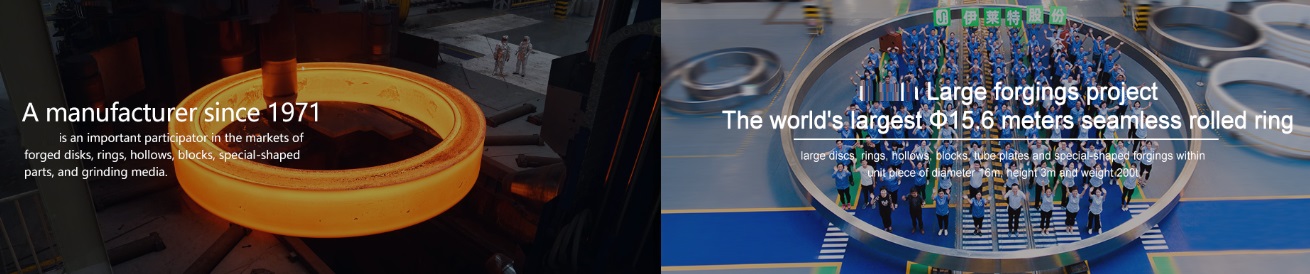

In the field of nuclear power, we maintain a manufacturing record of diameter 15.6 meters in forging rings worldwide;

In the field of pipe flanges, we have more than 20 years of export experience, and obtained the certification of the eight countries classification society;

In the field of mine grinding, our export volume of forged grinding steel balls ranks among the top five in the industry;

Grinding Media

Rolled balls

Forged Balls

Casting Balls

Grinding Rod

SDYL's history can be traced back to 1971. now the group has 5 subsidiaries and one overseas manufacturing site, covering an area of 350,000 m2 and with 1,300 employees. For nearly half a century, It has always been steadfastly devoted to the forging industry. From offshore wind turbines on the Atlantic coast to the oil fields deep in the deserts of the Middle East, to mines in the lofty mountains of Peru, our products have made their mark. Adhering to the values of “honesty, humility, perseverance and work ", SDYL is committed to creating sustainable value for global customers through high-quality products.

Certifications