XABL Additive Manufacturing Technology Group is a high-tech enterprise specializing in industrial-grade metal additive manufacturing (3D printing). It has established a relatively complete metal 3D printing industry ecological chain, and its overall strength is in a leading position in the field of metal additive manufacturing at home and abroad. .

XABL was founded in July 2011. The company's founding team came from the team of Professor Huang Weidong from the State Key Laboratory of Solidification Technology of Northwestern Polytechnical University. This team began to study metal additive manufacturing technology in 1995. It is one of the earlier teams that carried out related research at home and abroad. One. The company's business covers R & D and production of metal 3D printing alloy powder materials, R & D and production of metal 3D printing equipment, metal 3D printing customized product services, metal 3D printing process design development and related technical services (including metal 3D printing customized engineering software) Development, etc.).

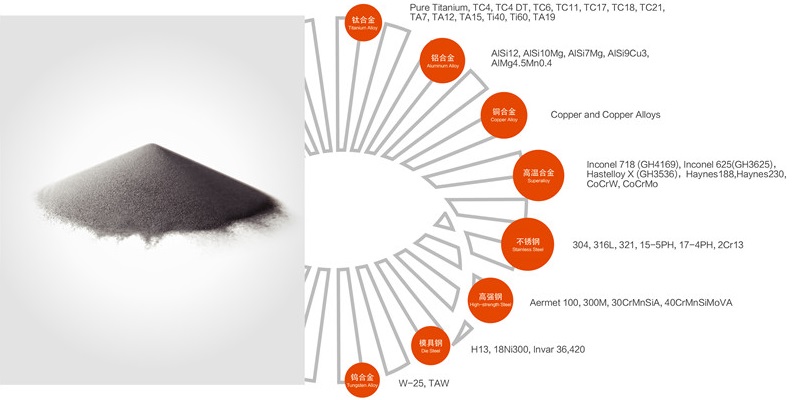

Additive alloy powder materials include titanium alloys, superalloys, aluminum alloys, copper alloys, stainless steel, mold steel, high-strength steel, and more than 50 types of materials. The company has a 3D printed metal materials research and development team, which can provide high-quality alloy powders with sizes covering various particle sizes, and the composition meets relevant technical standards such as navigation marks, national military standards, ASTM, AMS, ISO, SAE, etc.

The company's main customers include AVIC affiliated units, aerospace science and technology affiliated units, aerospace science and technology affiliated units, aviation development group affiliated units, COMAC, China Shenhua Energy, CNNC affiliated units, CSIC affiliated units, and various scientific research institutions Wait. The company is also a qualified supplier of 3D printing services for Airbus.

The company's high-precision, high-stability laser selective melting equipment BLT-S310 equipment, the core technical parameters such as forming accuracy, efficiency and stability, and process integration control have reached international advanced levels, and have been successfully exported to developed countries such as Germany and passed the European air The inspection and certification of the bus company has become the main equipment of the Airbus A330 additive manufacturing project, reversed the passive situation of high-end metal additive manufacturing equipment being monopolized by foreign countries, and realized the localization of industrial-grade high-end laser selective melting equipment.

XABL invested 700 million yuan to build a new metal additive manufacturing smart factory project in 2019, and will build a modern metal additive manufacturing smart factory integrating high-quality spherical metal alloy powder research and development, manufacturing, and intelligent additive equipment.