JSFJ Ceramic Technology Co., Ltd. was established in 1957, The company covers an area of 150,000 m2, including a research institute, a new material research center, a new material laboratory and three manufacuring sites with more than 800 employees.

The company undertake more than 10 technological projects above the provincial level, including:

Two National 863 programs

Six National science and technology innovation fund projects

Four projects in national and provincial torch program

One project in provincial scientific and technological achievements transformation

Four projects in provincial science and technology research projects and provincial science and technology program

113 patents, including 22 invention patents and 91 utility model patents

One national standard enactment or Five mainly national industry standard enactments

Four national key new products

JSFJ's main products: honeycomb ceramics, the inorganic ceramic film,the high-temperature ceramic film and gas-solid separation device, the Load-bearing bar girder of sulfuric acid absorption tower.

Products

Honeycomb Ceramics

The company began to develop honeycomb ceramics in 1984 and it is the earliest enterprise in China to develop and produce honeycomb ceramics. For more than 30 years, the company has adhered to the goal of the world's advanced level, filled the gap with the industry with innovative technology and products, witnessed and participated in the milestone development of honeycomb ceramics in China.

At present, honeycomb ceramics has formed four series of products: honeycomb ceramic carrier for gasoline engine exhaust gas purification (TWC), honeycomb ceramic carrier for diesel exhaust gas purification (DOC / SCR), Honeycomb ceramic carrier (DPF) for diesel soot particle filtration and honeycomb ceramic carrier for industrial exhaust gas catalytic purification. The annual production capacity reaches 8 million liters. The honeycomb ceramics has become the prefered source of many automobile catalyst manufacturers all over the world, with customers from more than 20 countries in Europe, North America , Asia and Africa.

Inorganic ceramic membrane

High Temperature Ceramic Membrane Filter Tube

The achievement of National 863 project "high temperature ceramic membrane filter tube"

The National High-Tech Research and Development Program (863 Project), a high-temperature ceramic membrane filter tube was jointly developed by JSFJ, Tsinghua University, Hainan University and China University of Petroleum in 2010. With the strong support and assistance of well- known enterprises in the China chemical industry, it has been successfully applied to the company's Shell coal gasification production unit. The ceramic filter tube has been continuously and stably operated, and its technical performances such as filtration precision and filtration gas flow rate have reached the production process requirements of the company.

The 1500mm large-size SiC asymmetric ceramic filter tube was successfully developed and commercialized. The advanced level of similar foreign products was reached in terms of length, working temperature, porosity, export dust concentration and separation efficiency. It has filled the gap in Chinese products in this field and broke the monopoly position of foreign products. The research results have reached the international advanced level.

At present, the high-temperature ceramic membrane filter tube has obtained 9 national invention patents and 2 utility patents.

High Temperature Asymmetric Ceramic Membrane Filter Tube

High Performance Microporous Ceramic Fiber Composite Membrane Filter Tube

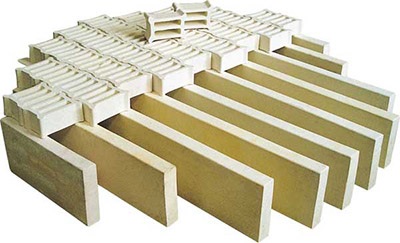

Sulfuric Acid Absorption Tower

JSFJ independently researches and develops the large-scale sulfuric acid absorption tower load-bearing beam with national invention patents, which filled the domestic gap and changed the long-term dependence on importing products. It was listed as the National Innovation Fund Project and the National Torch Program. It is also a drafting unit for national industry standards.

The product is made of ZrO2 phase transformation toughening and reinforcing Molai porcelain and unique molding and firing process. It is an ideal filler supporting device for large packed towers.

The company has been rated as a key national high-tech enterprise, advanced enterprise of intellectual property rights in Jiangsu, intellectual property strategy demonstration enterprise, It is also a non-metallic materials backbone enterprise. It passed the ISO900-2008 quality management system , ISO / TS16949-2009 quality management system certification, passed iso14001: 2015 environmental management system and ohsas18001-2007 occupational health and safety management system certification.