Nickel-plated carbon fiber

After the surface of the carbon fiber is metallized, its conductivity can be improved by dozens of times. It is an ideal filler for conductive plastics. SZFD uses proprietary technology with independent intellectual property rights to become a leading manufacturer of domestic metalized carbon fiber, and its product performance reaches the level of similar foreign products.

Product Overview

After the surface of the carbon fiber is metallized, its conductivity can be improved by dozens of times. It is an ideal filler for conductive plastics. SZFD uses proprietary technology with independent intellectual property rights to become a leading manufacturer of domestic metalized carbon fiber, and its product performance reaches the level of similar foreign products.

Features

• Dense and uniform metal layer structure

• Strong bonding between metal and carbon fiber, it won't peel off after repeated cold and hot cycles

• Does not damage the fiber and maintains the original high mechanical properties of carbon fiber

• Has excellent thermal and electrical conductivity and extremely low expansion coefficient

• Extremely high electromagnetic shielding performance

Application

Military, aerospace, automotive, electronics, machinery, chemical and other industries.

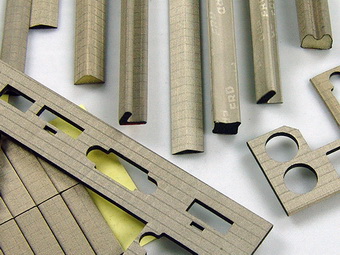

Conductive plastic device

Excellent shielding effectiveness (30MHz-10GHz): 60-85dB;

Low product density and weight reduction of up to 50%;

Better corrosion resistance and longer service life;

Flame retardant rating up to UL94-V0

Introduction to conductive plastics:

Conductive plastic is a functional polymer material that uses resin as a base material and conductive additives, and is processed by the processing method of plastic. Generally speaking, there are four forms of electrical conductivity of an object: insulator, semiconductor, conductor and superconductor. Conductive plastics have achieved a huge change from insulators to semiconductors to conductors, and it is the largest span of all materials that can accomplish this. Compared with traditional materials, it has the characteristics of light weight, easy molding, and adjustable resistivity, and can be easily synthesized or compounded into a variety of structures through molecular design. Conductive plastics can be classified according to their conductive properties: insulators, antistatic bodies, electrical conductors, and high electrical conductors; they can be divided into structural conductive plastics and composite conductive plastics according to their production methods; they can be divided into antistatic materials, conductive materials, and Electromagnetic wave shielding material.

• The substrate can include: PC / ABS, PC, ABS, PA, PPE, etc .;

• The main conductive fibers are: nickel-plated carbon fibers, stainless steel fibers, etc .;

• Conductive plastic has both EMI shielding and grounding functions.

Compared with metal materials, the advantages of conductive plastics:

• Design shielding effectiveness according to product requirements;

• Good anti-corrosion performance and long service life;

• Can process products with complex structures;

• No secondary processing, less waste and fast delivery;

• Small production loss, reducing production costs;

• Shielding gaskets are not required for seams, reducing installation time and costs;

• Low density reduces transportation costs.

Performance characteristics of electromagnetic shielding grade * conductive plastic:

• Surface resistance (Ω): 0.5 ~ 250

• Shielding efficiency (30MHz-10GHz) (dB): 40 ~ 85

• Density (g / cm3): 1.2 to 1.4

• Tensile strength (MPa): 50 ~ 120

• Bending strength (MPa): 70 ~ 150

• Flexural modulus (MPa): 2400 ~ 6000

• Working environment (℃): -40 ~ 90

• Flame retardant rating: UL 94 V-0

• Color: black, gray, blue-gray, etc.

* Note: According to the difference in surface resistivity, conductive plastics are generally divided into antistatic composite materials (surface resistivity 109 to 1012Ω / sq), static elimination composite materials (surface resistivity 106 to 109Ω / sq), and conductive composite materials (surface resistance Rate 103 ~ 105Ω / sq) and electromagnetic shielding grade material (surface resistance 100 ~ 103Ω)

Modified plastic with conductive function. The product is used in electronic components and plays the role of anti-electromagnetic wave interference and anti-static.

Application areas:

Communication equipment, computers, mobile phone terminals, automotive electronics, home appliances and other fields

Conductive cloth pad

Conductive and anti-corrosive conductive fiber cloth is lined with PU foam with low compressive force and has good shielding effect. The conductive fiber cloth is woven from metal fibers composed of copper and nickel on the surface of Polyester fiber. The bottom layer of the fiber is copper with high conductivity, and the surface layer is nickel metal that is resistant to oxidation and corrosion.

Introduction of conductive cloth products (conductive cloth pads)

At present, SZFD conductive cloth products are mainly composed of the following types of products:

SZFD's conductive cloth products projects now have independent research and development, design and production capabilities, and a number of technologies are leading the domestic counterparts. For example, SZFD launched its self-developed halogen-free flame-retardant conductive cloth padding products in early 2009. The domestic blank of this product. SZFD currently has 24 fully automatic high-speed production lines with a monthly production capacity of more than 7 million meters.

Among them, the conductive cloth pad product series accounts for 80% of the conductive cloth products. The related customers have already covered many applications such as consumer electronics, communications, automotive, medical, military and other fields.

The conductive cloth pad is made of conductive fiber cloth with conductivity and corrosion resistance, and is lined with PU foam with low compression force, which has a good shielding effect. The conductive fiber cloth is woven from metal fibers composed of copper and nickel on the surface of Polyester fiber. The bottom layer of the fiber is copper with high conductivity, and the surface layer is nickel metal that is resistant to oxidation and corrosion. The combination of copper and nickel provides excellent electrical conductivity and shielding. The conductive cloth pad can obtain good shielding effect in the frequency range of 100KHz to 1GHz.

The conductive cloth pad is particularly suitable for occasions with limited capacity and closing pressure, and the cost is low. It is particularly suitable for use in high-performance shielding where good fit is required. It can be widely used in electronic cases, cabinets, indoor cases, Industrial equipment, notebook computers, mobile communication equipment, etc.

Conductive Cloth Pad (FoF)

Conductive cloth pads, that is, conductive cloth-wrapped foam pads, are components based on cloth that have conductivity and elastic properties and have certain anti-electromagnetic interference functions for preventing electronic equipment from passing electromagnetic waves. In order to provide more useful information to customer design engineers, we introduce the product characteristics, types, materials, standard size and configuration of conductive foam pads here. If these contents do not meet your needs, please contact our engineers, we will design and produce the products you need according to your needs.

Advantages of conductive cloth pads

Good conductivity, high shielding effectiveness (≥80dB)

Good oxidation resistance and corrosion resistance

Good abrasion resistance, high reliability (≥1 million times)

Very soft, suitable for occasions that cannot provide greater pressure

Low price, very ideal shielding material

Simple and diverse installation methods, suitable for paste and card slot

Product complies with ROHS, Halogen Free, REACH, UL94-V0 requirements

In general, conductive foam is an excellent cost-effective EMI shielding material.

Related testing equipment for conductive cloth

High-precision image measuring instrument

Universal electronic material tester

Tensile testing machine

SZFD Dynamic Resistance Tester

Salt spray testing machine

Fabric Abrasion Tester

ROHS Tester

Density test electronic balance

Flame retardant tester

Precision Electronic Thickness Gauge

Constant temperature and humidity tester

Optical microscope

Four-probe resistance tester

Digital DC Low Resistance Meter

Customer Reference

Huawei, ZTE, Foxconn, Flextronics, Dell, Nokia, Lenovo, BYD, Emerson, Delta, Inventec, Asus, Alcatel-Lucent, IBM, Lite-On, Mitac, Jabil, H3C, New Meiya…