SDTC Industrial Ceramics Research Institute is the only national industrial ceramics research institute in China. SDTC Industrial Ceramics Research Institute has always stood at the forefront of industry technology, leading the development direction of China's advanced ceramic materials technology and industry, and opening up research in many fields. First. SDTC is the national ceramic industry innovative enterprise, the National Industrial Ceramic Engineering Technology Research Center, the National Industrial Ceramic Standardization Technical Committee (SAC / TC194) relying unit, and the international ISO / TC206 fine ceramic technical committee domestic technology focal point.

Relying on the innovation platform, SDTC has achieved many domestic firsts. The first continuous boron nitride fiber, the first quartz ceramic roller for glass horizontal tempered roller kiln in China, the first set of high temperature and high pressure coal fly ash filter in China, and the first million volt prop for the UHV AC test demonstration project Insulators were born here.

For decades, SDTC has formed its own unique high-performance ceramic transparent materials, ceramic heat insulation materials, special ceramic fibers, special functional coatings, advanced ceramic precision processing technology, high-temperature ceramic membranes and equipment, industrial solid waste Comprehensive utilization of seven university subjects, built four major innovation platforms for key common technology research and development, testing and evaluation, standardization and engineering transformation, incubating the four major industries of microcrystalline alumina, fused silica, high voltage electric porcelain and high temperature ceramic membrane equipment. Has undertaken more than 100 national "863" plans, national scientific and technological research projects and national defense scientific and technological research projects; won 9 national awards, more than 100 provincial and ministerial awards; has 93 patents; presided over the formulation and revision of 43 national and industry standards . Among the dozens of new materials developed and more than 100 new products, more than 20 are listed as national-level new products, filling the domestic gap, and making a major contribution to the building materials industry and the defense industry's supporting special ceramic materials.

Products

Silicon nitride ceramic products

Silicon nitride ceramic material is a special ceramic material with excellent comprehensive performance; SDTC Ceramic Research Institute has more than 40 years of research and development experience in silicon nitride ceramic material, and has undertaken more than 30 countries from National key research projects, high-tech projects and military industry research projects from the "12th Five-Year Plan" period, obtained 17 research results above the ministerial level, obtained 6 patents, and established "800,000 tablets" in the mid-1990s "Si3N4 Ceramic Bearing Ball" and special-shaped product production lines form a research and development platform for Si3N4 ceramic products that integrates scientific research and production; it has a complete set of production technology equipment from raw material processing, molding, firing and processing.

Main application areas:

1) Machinery industry: Silicon nitride ceramic shaft balls can be widely used in electric spindles of high-speed machine tools, bearings of wind turbines, and high temperature and corrosion resistance fields;

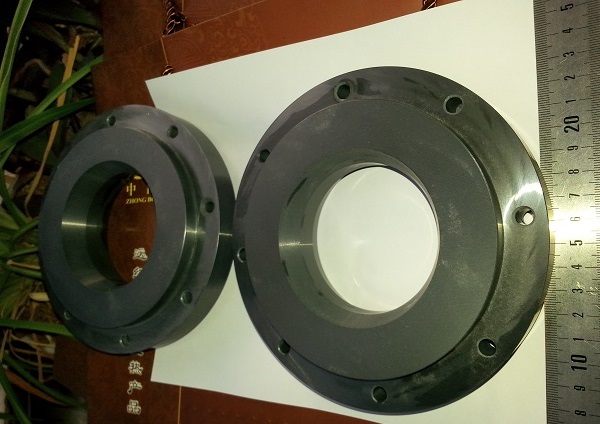

2) Metallurgical industry: due to the non-wetting characteristics of silicon nitride ceramics and aluminum liquid, silicon nitride ceramic parts are widely used in aluminum smelting and casting, such as protection tubes, riser tubes, hooks, etc .; silicon nitride ceramic resistance The water ring can be applied to non-destructive flaw detection units for seamless steel tubes; silicon nitride metallurgical rolls can be used for steel production, etc .;

3) Petroleum industry; can be used for petroleum exploration, etc .;

4) The field of high temperature wear resistance and corrosion resistance; silicon nitride ceramic positioning blocks can be used in the production of titanium sponge; silicon nitride ceramic inserts are used in the high temperature reflux area of supercritical industrial boiler swirl burners, etc .;

5) In the field of wave-transmitting materials; due to its excellent wave-transmitting properties, silicon nitride ceramic plates can be applied to the roof of microwave ovens, the detection windows of level gauges, etc .;

6) Auto parts: such as rocker inserts, turbine rotors, cam tappets, etc.

Silicon nitride ceramic turbines-mainly used in turbochargers of high-end automobile engines.

Silicon nitride ceramic bearing ball-widely used in machine tools, wind power generation, petroleum, chemical industry and other industries

Silicon nitride ceramic water blocking ring-the main purpose is to be used on the large-scale seamless steel pipe on-line nondestructive flaw detection machine, replacing the imported products in Japan, and the life span is 2-3 times that of similar products in Japan.

Alumina ceramic burning plate

Relying on the advanced technology of "National 863 Major Special Project", our company produces alumina ceramic fire-bearing plates. The surface smoothness, appearance and internal quality, and service life are far superior to similar products produced by other processes. The products are widely used in powder metallurgy and magnetic Materials and other industries.

Alumina series ceramic plate

The alumina series chip ceramics produced by our company relying on the advanced technology of "National 863 Major Project" are mainly alumina ceramic substrates (boards). The product has high density, high thermal conductivity, high insulation, low dielectric loss, and high reflectivity. , Good thermal stability, high dimensional accuracy, good smoothness and flatness, and other excellent characteristics, widely used in thick film hybrid integrated circuits, LED lighting, IGBT power modules, DBC copper clad laminates, thermal printers, ozone generators, semiconductor refrigeration Devices, crystal oscillators, high-voltage resistors, automobiles and power tools, and other power electronics and optoelectronic communication fields. They can also be used as gaskets, sealing sheets, heat sinks, and support plates in industries such as precision machining, semiconductor components, and electronic components. , Use of burning plate.

At present, the alumina ceramic substrates (boards) produced by our company are of two types: die stamping sheets and laser cutting sheets, which can provide various specifications of substrates (boards) with a length and width ranging from 1 to 300 mm and a thickness of 0.4 to 4 mm. , The performance and accuracy of the product can fully meet customer requirements.