Benewtec Machining Solutions is the world's leading provider of machines, Automation solutions and services to the tool and mold making industry and to manufacturers of precision components. Products range from electric discharge machines and high-speed and high-performance Milling machines – including clamping and palletization systems – to 3D Laser surface texturing machines, services, spare and expendable parts, consumables and Automation solutions.

Competences

Benewtec Machining Solutions’competences extend far beyond our machines to include peerless customer support, deep application expertise, innovation driven by the market, and standard-setting excellence as measured by our customers’success.

Benewtec Competences

Application expertise

Benewtec Machining Solutions has comprehensive application know-how, a wide range of Milling, EDM and Laser texturing machines, Automation solutions, and the world’s most comprehensive Customer Services package. Benewtec Machining Solutions is the global partner uniquely positioned to help customers exceed expectations and outpace their market competitors.

Highly efficient machines

The precision, speed and reliability of Benewtec Machining Solutions’products trigger our customers’ success. The increased productivity at lower operating costs throughout our products’ lives means greater value for our customers

Market-driven innovation

Benewtec Machining Solutions is pioneering the development of new application solutions, technologies, products and services. With our comprehensive technical expertise and an eye to the future, we increase our customers’competitive edge.

Standard-setting excellence

Benewtec Machining Solutions aims to be regarded as the global reference for excellence in precision machining. We measure our excellence by our customers’ success. Every Machining Solutions employee, product and service is focused on enabling our customers to outperform their competitors.

Manufacturing Capabilities and Solutions

In Milling, EDM, Laser texturing and Automation technologies– from automotive and aerospace and aeronautics to medtech, electronic components, and Information and Communications Technology (ICT) – Benewtec Machining Solutions’ customers worldwide depend on our application know-how and process expertise. The Machining Solutions’ customers range from small and medium-sized toolmakers to global corporations.

Milling

High speed milling: precision and quality for tool- and moldmaking

The Machining Solutions’range of high-speed milling centers — engineered and built in Switzerland — boast the essential structural design, high-speed spindles, high feed rates, axis mechanism and best-in-class acceleration for machining complex three-dimensional surfaces across a wide range of applications.

Milling – High Speed Machine

Measurements

High speed machining centers: Mikron HSM

High speed milling centers are 10 times faster than conventional milling machines in terms of cutting speed. Greater accuracy and better surface finish achieved

Mikron XSM: Ultra high speed machining centers

Turning and milling in one clamping operation

In contrast to High Speed Cutting, this technology mainly is used for the machining of twodimensional geometries. The cutting depth ap and the stepover ap along with the machining feed allow calculation of the material removal per unit of time (cm3/min). This process in particular is suitable when it comes to the removal of large volumes of material or the machining of difficult to cut materials. High power, high torque spindles are a must. Primarily used cutting tools are insert type milling heads, specific high performance end mills, drills, boring heads and special tooling.

Machining centers belonging to the Mikron VCE Pro series: More robust, more reliable, better performance, better ergonomics

For universal application in the workshop for a large range of applications the Mikron VCE Pro-Range is the machine to be chosen. Whether 2½D or 3D application, the machine won't let you down. The standard machine has a performance, which fulfills most of the customers' demands. With additional options the machine can be customized.

EDM

Die-Sinking EDM Family – Dive into your future-shaping solutions

Whatever the current—or future—die-sinking electrical discharge machining (DSEDM) challenge, the Machining Solutions’ new FORM family of DSEDM machines are future-shaping solutions to advance manufacturers’ success.

Wire cutting EDM

Wire EDM machine uses a metallic wire (electrode) to cut a programmed contour in a workpiece. Extrusion dies and blanking punches are very often machined by wire cutting. In the machining area, each discharge creates a crater in the workpiece (material removal) and an impact on the tool (wear of the tool/electrode). The wire can be inclined, thus making it possible to make parts with taper or with different profiles at the top and bottom. The wire is usually made of brass or stratified copper, and is between 0.02 and 0.33 mm diameter.

Advanced Manufacturing Technologies

Discover a new dimension of freedom of design, process optimization and higher productivity with Benewtec Machining Solutions' advanced manufacturing solutions. Confidently explore new business opportunities, thanks to the increased performance allowed by Laser texturing, Additive Manufacturing and Laser micromachining.

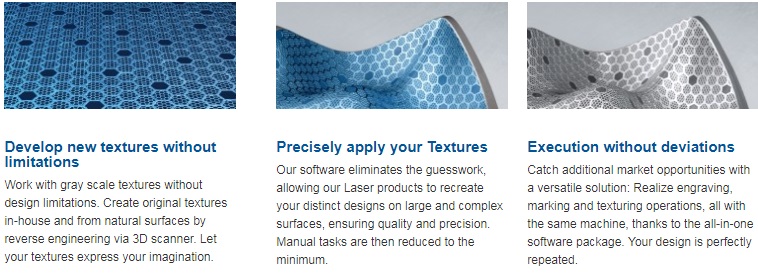

Laser texturing

When a new manufacturing era begins

Aligned with the Machining Solutions’ vision of the smart factory of the future, our Laser texturing technology helps you overcome your daily manufacturing challenges while allowing you to innovate without compromise, speed up your time to market, and reduce your environmental impact. Our Laser texturing solutions allows you to easily and with infinite repeatability make your distinct mark on 3D geometries in a wide range of industries such as automotive interiors, automotive lighting, tire, consumer electronics, packaging, cosmetic, luxury goods, medical, home appliances, tooling, mold making, and lifestyle/consumer products like shoes, sporting products and more. Laser texturing is poised to transform the texturing of plastic injection molds and allow designers to innovate without limits thanks to our unique Laser texturing product portfolio answering your specific needs : Laser texturing, Laser blasting, Laser engaving, and Laser etching services can be answered with the same and unique solution.