On December 4th, China’s leading Vapor Chamber technology company, SZOF Electronic Materials Technology Group, released information that SZOF broke through the traditional laying copper mesh or copper powder sintered capillary core structure, and was the first in China to adopt a precision etching microstructure integrated capillary core process. Successfully developed 0.3mm ultra-thin VC soaking plate, and reached a stable process level for mass production.

Hay Think learned that SZOF has developed a 0.3mm ultra-thin VC soaking plate with an etched capillary core, which reduces the overall thickness by about 50um, which not only simplifies the process but also reduces the cost, making it possible for the VC soaking plate to enter low-end mobile phones.

SZOF said that the thinnest thickness of VC soaking plates in mass production in the industry is 0.35mm. The launch of 0.3mm ultra-thin VC soaking plates by SZOF will undoubtedly provide more room for various product designs. In addition, the etched capillary core and continuous support column structure support products can achieve a flexible design of 180° bending, which is convenient for thermal management design for various customer products. At the same time, due to the special structure design and advanced technology, SZOF`s etched capillary wick has a liquid absorption height of 13.5cm, a liquid absorption speed of 8mm/s, and can support 5W heat dissipation power, which can fully meet the requirements of daily electronic products such as mobile phones Heat dissipation requirements.

About SZOF

Established in 1980, SZOF Electronic Materials Technology Group is a functional solution provider for improving the reliability of intelligent electronic equipment with its independently developed and produced electromagnetic compatible, and thermally conductive materials to protect intelligent electronic devices in the complex and harsh electromagnetic interference environment.

Over the years, It has accumulated rich experience in electronic material innovation, manufacturing in communications equipment, medical electronics, machinery manufacturing, rail transportation, and new energy.

R&D Capabilities

● Formulation technology of polymer composites

● EMC detection and design rectification ability

● Synthetic graphite sintering technology

Products & Applications

● Thermal insulation material for improving heat dissipation of equipment power devices

● Various shielding materials to solve equipment radiation and interference

● Industrial filter to improve power quality

● Diversified power filter for solving conduction problems

● Customized service to comprehensively solve EMC problems

…

Thermal pad

Thermal grease

Full-conductive Foam

Wave Absorbing Rubber

Metal absorbing wave

Heat storage PCM

IP protection materials

…

Products

Synthetic graphite sheet, multilayer graphite and natural graphite

Thermal pad

Thermal gel,Thermal grease

Form in Place/FIP conductive rubber gasket

Full-conductive Foam

Fabric over foam

Wave Absorbing Rubber

Metal absorbing wave

The metal absorbing sheet is composed of a thin magnetic conductive material with high magnetic permeability and low loss, and has a small size effect and an interface effect peculiar to the nano crystal structure. It has stable reliability and a certain flexibility, and can acheive ideal magnetic isolation effect in a magnetic field.

Heat storage PCM

IP protection materials

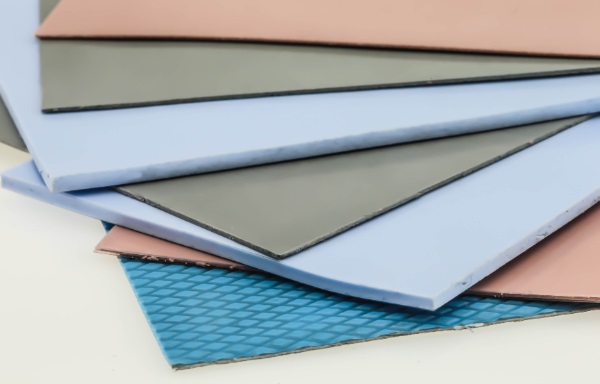

Vapor Chamber

Vapor Chamber is a vacuum cavity with a fine structure on the inner wall. The purpose of heat dissipation is achieved through the vaporization and condensation of the cooling liquid in the cavity, which is usually used for electronic products that require a small volume or need to quickly dissipate high heat.

Heat Pipe

The heat pipe is a kind of heat-conducting material. It makes full use of the heat-conducting principle and the fast heat-transfer properties of the phase-change medium to quickly transfer the heat of the heating object to the outside. Its thermal conductivity of heat pipe exceeds that of any known metal.

…

Applications

Intelligent Termimal

Smart Home

Telecommunication

New Energy Automobile

Medical Equipment

Industrial Automation

Power & Energy

Big Data Processing

Customer Reference