On June 11, the China National Space Administration announced the panoramic view of the landing site, the “Chinese Imprint” and the “landing group photo” taken by the Mars Rover Zhurong. The release of the first batch of scientific image maps marked the complete success of my country's first Mars exploration mission.

The air on Mars is thin and cold, and the temperature difference between day and night is large. The average temperature is only minus 63 degrees Celsius. It is like the deserted Gobi desert environment on the earth, with pits and pits on the surface, and extreme weather such as sandstorms often occur. The conditions are very harsh. In such a harsh environment, the "Zhurong" rover can complete its mission, and the materials it uses are indispensable.

Aluminum-silicon encapsulation shell: a packaging solution for core key components such as TR components of the probe landing system.

Function: To ensure the safety of the probe's landing system circuit, and to put on a safe and reliable "protective suit" for the internal circuit of the device to ensure the safe and stable landing of the probe on Mars.

Product supplier: HFSD Electronic Material Technology Group

About HFSD

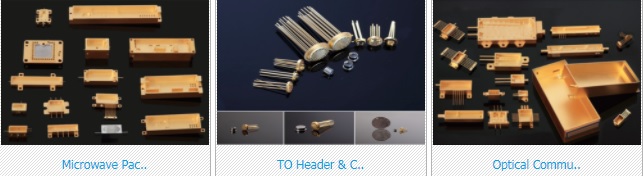

HFSD is a high-tech enterprise which focuses on the research and development of high-end packaging and electronic material, The products fields cover metal packaging ,ceramic packaging and packaging materials, and the supporting solution is available for integrated packaging requirement.

It is now possessed with the advanced R&D and production line for metal packages, AlN ceramic materials and electronic paste. It's products are widely used in the civilian industries such as optical communication, high power laser, microwave, hybrid integrated circuit, power electronics, new materials etc. The current annual capacity of metal packaging packages in the company reaches 3 million sets, DBC substrate (5 inch x 7 inch) 1 million pieces, Aln substrate 4000m2 and electronic paste 60 ton.

Its customer groups can be found in dozens of countries and regions around the world. The company is renowned both inside and outside the industry for its complete design, research and development, manufacturing, testing and reliability assurance capabilities and mature standardized management level.