From T300 to T1000, ZFSY Carbon Fiber Technology Corporation has achieved large-scale industrial production and has been operating stably. CTO Dr. Zhang led his team spent 13 years from inspiring independent research and development of carbon fiber to winning the first prize of China's national scientific and technological progress.

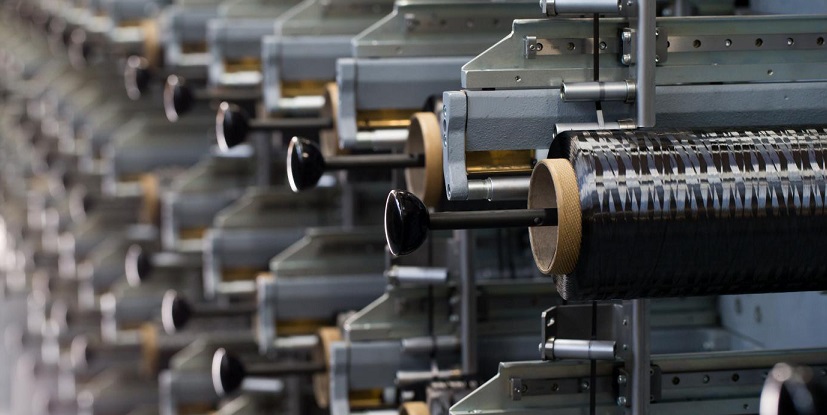

On July 2, 2015, ZFSY's newly-built "Key Technology and Thousand Ton-level Engineering of High-Performance Dry Jet Wet-Spinning Carbon Fiber" project passed the national acceptance, marking the new progress of domestic carbon fiber.

In September 2015, T800 carbon fiber, which reached the level of aerospace products, achieved industrialized mass production.

In May 2016, the 1,000-ton T800 production line was put into operation, and China’s first 1,000-ton T700/T800 carbon fiber production line with the international advanced level was built, leading the progress of China's carbon fiber industry.

In 2018, the 100-ton T1000 carbon fiber production line completely independently researched and developed has been put into production and is running smoothly, marking that China's high-performance carbon fiber has reached a new level and entered a new era of higher quality development.

…

Break through the core technical problems of dry jet wet spinning carbon fiber

As China has made important progress in wet-process carbon fiber technology, the international carbon fiber powerhouse has not stopped to relax, and they are fully developing dry-jet wet spinning technology during the same period. Compared with wet-process carbon fiber, the use of dry-jet wet spinning technology has greatly improved mechanical properties, significantly improved production efficiency, and significantly lower energy consumption. It has become a new technology for high-performance carbon fiber. Dry jet wet spinning is also recognized as a spinning technology that is difficult to break through in today's carbon fiber industry. Only two companies in Japan, Toray and Hexcel in the United States, have their preparation technology and equipment have been monopolized and blocked.

The development of dry jet wet spinning technology is the mainstream of carbon fiber in the future. Carbon fiber above T700 grade produced by dry jet wet spinning process is a high-performance material urgently needed for modern national defense, and the most important new material in the manufacture of cutting-edge equipment for national defense. This new material plays a role in resistance to deformation, temperature difference, and weight reduction. Plays a vital role.

Won the first prize of National Science and Technology Progress Award

Dry-jet wet spinning is highly dependent on the high molecular weight, narrow distribution, and high homogeneity requirements of the stock solution. At the same time, there are key technologies such as high-viscosity fluid spinning forming, dry-jet wet spinning coagulation and aggregation state control, dense structure, high drafting, and homogeneous pre-oxidation. The problem is that it is urgent to break through the bottleneck and build an independent dry jet wet spinning carbon fiber technology and equipment system.

After more than 3 years of arduous exploration and experimentation, ZFSY has broken through the core technical problems of dry jet wet spinning carbon fiber and has achieved a series of major scientific and technological achievements. They innovated and developed high-capacity polymerization and homogenization dope preparation technology, overcame the key technology of dry-jet wet spinning of high-strength/medium-mode carbon fiber precursors, independently developed PAN fiber rapid homogenization, pre-oxidation and carbonization integration technology, and built a technology for the first time. The industrialized production system of dry-jet wet spinning thousand-ton high-strength/100-ton medium-mode carbon fiber with independent intellectual property rights. Through the integrated innovation of technology and equipment, the efficient production of high-performance carbon fiber has been realized, and the products have reached the international advanced level of similar products. It has become the first and the third company in the world to overcome the technical problems of dry-jet wet spinning, filling the dry-jet wet spinning process in China. The blank of high-performance carbon fiber production technology represented by wet-jet spinning technology broke the long-term monopoly of foreign giants in the Chinese market.

On the morning of January 8, 2018, the National Science and Technology Awards Conference was grandly held in the Great Hall of the People in Beijing. ZFSY led the completion of the "Dry-jet wet spinning 1,000-ton high-strength/100-ton medium-mode carbon fiber industrialization key technology and application" project won the first prize of National Science and Technology Progress Award.

At present, ZFSY has systematically mastered T700, T800 thousand-ton technology and T1000, M30, and M35 100-ton technology, and its market share in the domestic carbon fiber market has reached more than 60% year after year, which has greatly promoted China's carbon fiber composite The development of the material industry.

ZFSY has built a capacity of 10,000 tons of carbon fiber and has become China's major carbon fiber provider for aerospace, defense and military industries. It plans to build a capacity of 100,000 tons of carbon fiber in 2030 and become a leader in the development of international carbon fiber technology and new applications.