One of the world's largest CVD graphene mass production companies

Speaking of graphene in China, I have to mention Professor Feng Guanping, the founder of China's graphene industry and the founding dean of Tsinghua University Research Institute.

In 2009, Professor Feng Guanping introduced more than 70 high-end graphene technical talents from overseas to start the graphene industry, including WXGF Graphene Technology Company.

WXGF is China's first batch of companies focusing on the research and development and production of graphene films, and has a core research and development team composed of a large number of returned doctors.

Under the leadership of Professor Feng Guanping, WXGF successfully solved the world problem of graphene film preparation and large-scale production, and built the world's first production line of CVD graphene transparent conductive film with an annual output of 30,000 square meters, taking the lead in the world Realize large-scale preparation of graphene. At present, WXGF has an annual output of nearly 200,000 square meters of graphene film, making it one of the world's largest CVD graphene mass production companies.

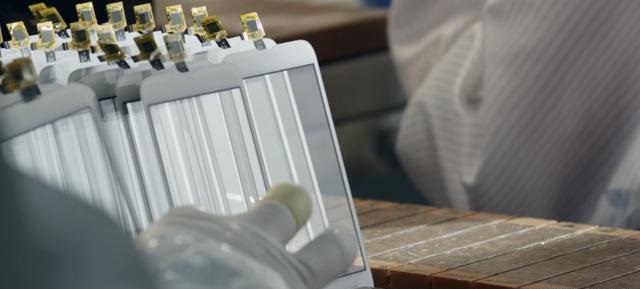

WXGF also has the world's first self-designed graphene touch sensor and touch screen production line. It is the first company in China and even the world to have independent intellectual property rights to realize the large-scale application of graphene to touch screens.

CVD method is an important technology for graphene film preparation

The graphene film prepared by the CVD method has the characteristics of controllable composition, quality and size. The process is simple and easy, the surface of the product is smooth and high quality, which is conducive to large-scale production, and it is most likely to achieve large-scale production and low cost. The graphene film is directly obtained, and the reprocessing process is simple. It is the first breakthrough in industrialization, and achieves high quality and large size, the most promising method for industrialization.

The principle of CVD method for preparing graphene film is: the carbon source is cracked to form carbon-based fragments under the action of high temperature and auxiliary gas, and then rearranged on the substrate to form graphene under the action of auxiliary gas. The temperature, pressure, gas flow rate, gas ratio, and cooling rate during the reaction will all affect the quality and layer thickness of graphene.

The growth of high-quality graphene often selects metal or metal plating on a specific substrate as the catalytic substrate, such as copper, nickel, ruthenium, and even iron, cobalt, platinum, gold and stainless steel, gold-nickel, cobalt-nickel alloys and other transition metals and The alloys have been used as metal substrates for graphene growth research, and the research on the growth of graphene on copper and nickel substrates is the most and most in-depth.

After nearly ten years of development, the CVD method has achieved a series of breakthroughs in the three aspects of large-scale, rapid preparation of copper substrates, and high-quality graphene films. However, due to the lattice mismatch of the interface materials, the graphene film has too high grain boundary density, the contradiction between growth speed and film growth quality, and the uniformity of large-area growth. It is necessary to achieve large-scale, rapid preparation and film quality at the same time. High these three goals are still a huge challenge.

WXGF has the world's leading CVD graphene preparation technology

WXGF uses a self-designed CVD graphene growth furnace and improved process conditions to reduce the density of the attached graphene grain boundaries, and the internal stress and carrier scattering are correspondingly reduced, and the carrier concentration and mobility are improved. The high-efficiency preparation of large-size and high-quality graphene is realized, and the difficult problems in the preparation of graphene films are overcome.

A series of innovative research results of WXGF technology have solved the bottleneck problem of high-quality graphene film materials that are difficult to produce at low cost and in batches, and established a stable production process for high-quality graphene films with core independent intellectual property rights to achieve high-quality graphite The batch preparation of olefin films will further point the direction for the high-end applications of high-quality graphene films and promote the sound and sustainable development of the graphene industry.