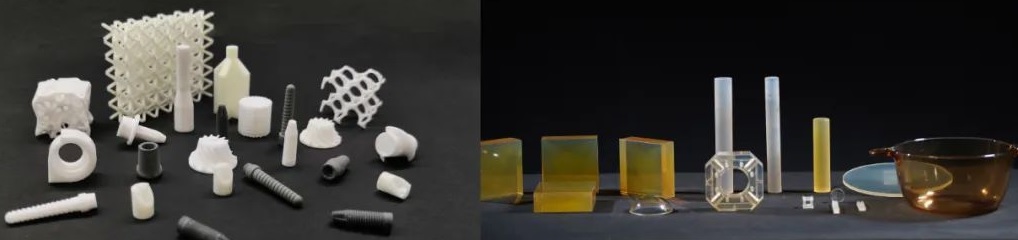

ZCGX Advanced Materials Technology Corporation is committed to the R&D and manufacturing of advanced technology ceramics and optical crystals.

The company was restructured from multiple national level research institutions for technical ceramics and optical crystals.

ZCGX has undertaken more than 10 national level "bottleneck" technologies and key core technology research tasks, focusing on the development direction of key disciplines such as nonlinear optical crystals, infrared optical materials, ultra-low expansion microcrystalline glass, ceramic transparent materials, ceramic anti thermal insulation materials, and silicon nitride ceramic bearings;

Breakthrough has been made in key material preparation technologies such as meter level ultra-low expansion microcrystalline glass reflectors for space cameras, large-sized and thick CVDZnS crystal growth, continuous high-performance ceramic fibers, G3 level ceramic bearing balls for aircraft engines, and high-temperature resistant ceramic springs, providing strong guarantees for China's independent and controllable key materials and meeting the needs of major national engineering projects:

Nitride ceramics have broken through the key technologies of forming, sintering, and precision machining of silicon nitride ceramic bearing balls, breaking foreign monopolies, and increasing the product qualification rate from 30% to 91%;

Accelerate the research and development of related technologies and production line layout for high thermal conductivity silicon nitride substrates, and mass production is equivalent to the advanced level of similar foreign products;

Dry method slender rod shaped pillar porcelain insulator products have successfully entered the international market;

Reduce the cost of ceramic fiber membrane products by 10%, and achieve ultra-low emission standards for nitrogen oxides, sulfur dioxide, and dust in the coking industry;

The dimensions of diamond film products produced by HFCVD method are determined by Φ Breaking through 150mm to Φ 300mm, efficiency increased by 4 times, with mass production capacity, reaching the international leading level;

Batch production of ultra-low wear microcrystalline alumina lining bricks;

…