Good news in the field of flexible foldable screens continues. Samsung launched the new Galaxy Z Flip, which is the first in the industry to achieve mass production and commercial use of ultra-thin flexible glass covers for folding screens. Due to the better screen experience and wear resistance of Ultra thin glass (UTG), Ultra thin glass (UTG) is expected to usher in a period of industrial explosion.

China's leading electronic ultra-thin glass technology giant HBDX Optoelectronics Technology Group has successfully produced 30-70μm Ultra thin glass (UTG) products through independent research and development and innovation, marking HBDX's new industry opportunity in the ultra-thin flexible glass field.

In order to fully realize flexible display, the display cover should have the characteristics of being repeatedly bendable, transparent, ultra-thin, and sufficiently rigid. Now some foldable mobile phone flexible screens use CPI materials. Although CPI materials have the basis for mass production, they have many problems in terms of wear resistance, surface texture, water and oxygen barrier, appearance creases, durability, etc., which seriously affect the life of the whole machine And user experience. Compared with CPI, foldable ultra-thin flexible glass has better flatness, transparency, heat resistance, surface hardness, scratch resistance, high strength, water and oxygen resistance, etc., because it retains the physical properties of the glass, and it also has super Thinness, flexibility and other advantages are considered the best cover material for flexible displays.

Ultra-thin flexible glass covers are gradually becoming a new choice for foldable mobile phones, and there is huge room for industry development in the future. But it has to be said that foldable glass still faces challenges. The impact resistance of ultra-thin flexible glass and panel cutting technology are the difficulties that the current technology needs to overcome. If you want to realize the further commercialization of ultra-thin flexible glass, the technology is still The essential.

HBDX foldable ultra thin flexible glass (UTG) research and development results

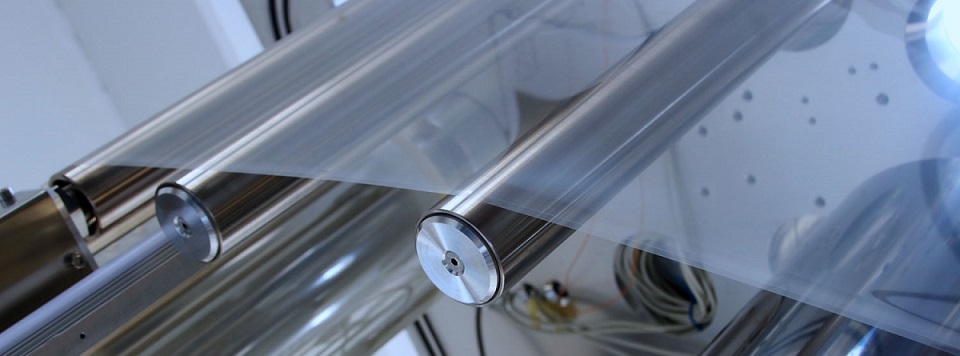

HBDX has been deeply involved in the field of electronic glass for many years. It started the research and development of foldable ultra-thin flexible glass two years ago. It has achieved technological breakthroughs. It has independently developed a complete set of technology and equipment for drawing ultra-thin glass, which can be drawn and produced. -70μm ultra-thin glass. Independently developed unique ultra-thin glass processing technology can effectively solve the problems of cutting and cracking of ultra-thin flexible glass. After chemical strengthening, it can achieve 200,000 consecutive bendings without damage, and the bending radius is less than 2 mm. The ultra-thin glass Various performance indicators have reached the international leading level, and samples have been sent to downstream customers.