WXHJ New Materials Technology Co., Ltd. is an enterprise specializing in the production of new metallurgical materials.

The company occupies a total area of 90 acres, a total construction area of 41,000 square meters, and a registered capital of 72 million yuan.The company is a member unit of the Electrical Steel Branch of the National Institute of Metals and a member unit of the National Distribution Transformer Energy Efficiency Improvement Industry Alliance.It is the only professional manufacturer of cold-rolled oriented silicon steel with independent intellectual property rights in JS Province.

The company's main product is cold-rolled oriented silicon steel, which has strong properties of low iron loss and high magnetic induction, and is widely used in the manufacture of core components of high-efficiency energy-saving transformers.

In recent years, with the in-depth implementation of the national energy conservation and emission reduction policy, the National Development and Reform Commission, the Ministry of Industry and Information Technology, and the General Administration of Quality Supervision have jointly issued a document calling for the implementation of a distribution transformer energy efficiency improvement plan, improving the efficiency of power transmission and distribution, and reducing coal-fired carbon emissions.

The company actively develops low iron loss and high magnetic induction oriented silicon steel (Hi-B steel), accelerates the development and production of Hi-B steel, the key raw material for the energy efficiency improvement of distribution transformers, and supports the smooth implementation of the national energy efficiency improvement plan for distribution transformers. At present, the annual production capacity of oriented silicon steel reaches 50,000 tons.

Products

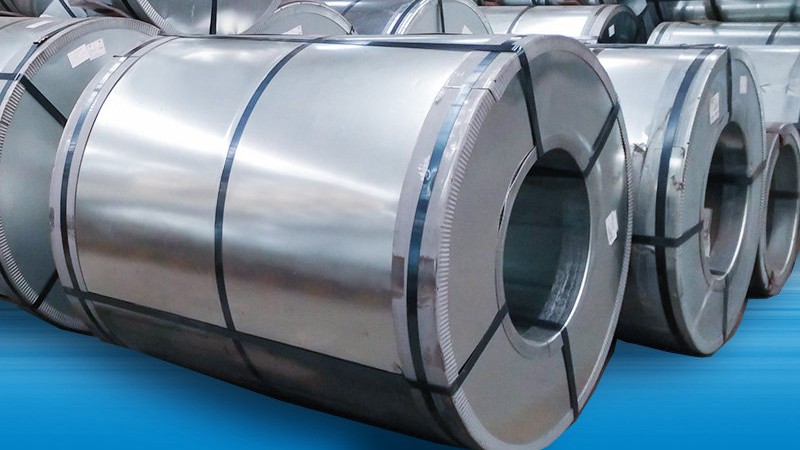

Cold Rolled Oriented Silicon Steel

The main purpose of cold-rolled oriented silicon steel strip is for transformer manufacturing, so it is also called cold-rolled transformer silicon steel. Compared with cold-rolled non-oriented silicon steel, oriented silicon steel has strong magnetic directionality; it has superior high magnetic permeability and low loss characteristics in the rolling direction of easy magnetization. The iron loss of the oriented steel strip in the rolling direction is only 1/3 of the transverse direction, the magnetic permeability ratio is 6:1, and the iron loss is about 1/2 of the hot rolled strip, and the magnetic permeability is 2.5 times of the latter.

High magnetic induction cold-rolled silicon steel strips are all single-oriented steel strips, which are mainly used in the manufacture of electromagnetic components such as transformers and chokes in the telecommunication and instrument industries. There are two main characteristics of its application. One is that under the condition of low current, that is, weak magnetic field, the material is required to have high magnetic properties in the range of weak magnetic field, that is, high μ0 value and high B value; the second feature is the frequency of use High, usually above 400Hz, even up to 2MHz. In order to reduce the eddy current loss and the effective permeability under an alternating magnetic field, a thin strip of 0.05-0.20mm is generally used.