Affected by the global Coronavirus (COVID-19) epidemic, the "four major families" of industrial robots have both experienced declines in revenue and net profit; from the 2019 financial report and the first two quarters already announced this year, the performance of the Chinese market is fair In addition, the performance of other markets was not satisfactory.

The 2019 financial report shows that ABB’s robotics and discrete automation orders were US$3.262 billion, down 11%; in the second quarter of 2020, FANUC’s robotics division’s order value was 43.9 billion yen, down 22% from the same period last year; in the second quarter of 2020, the library Card achieved revenue of 540 million euros, a year-on-year decrease of 32.1%; during the period from March to August 2020, Yaskawa Electric’s robotics division revenue was 65.396 billion yen, a decrease of 18.9% from the same period last year, with a profit of 2.486 billion yen, a plunge of 36.7 from last year. %.

In the context of the unstoppable decline of global industrial robot head manufacturers, from 2020 to now, the shipment volume of China’s leading robot and core robot parts manufacturer, NJES Robotics Technology Group, has increased by more than 50% year-on-year, and the annual shipment volume is expected to reach 5000-6000 units. From the perspective of specific performance, in Q1-Q3 of 2020, NJES achieved revenue of 1.763 billion yuan, an increase of 82.23% year-on-year; net profit attributable to the parent company was 85.42 million, an increase of 48.96% year-on-year.

Based on the technological, product and resource advantages formed in the field of robotics for many years, NJES CEO Zhu Chunhua stated that NJES may enter the first echelon of global industrial robots as early as 2025.

When it comes to industrial robots, the first word that pops up in most people's minds is basically: not making money. KUKA's net profit margin in 2017 was only 2.5%, and the highest FANUC net profit margin in 2017 was only 25%. This is even more obvious among some local Chinese brand robot manufacturers. Due to the late start, involuntary core components and lack of scale advantages, the cost of manufacturing robots for Chinese domestic manufacturers has remained high for a long time.

From 2017 to 2020H1, the gross profit margins of NJES industrial robots and intelligent manufacturing systems were 29.63%, 30.39%, 31.07%, and 35.42%, respectively, and the gross profit margin has been increasing year by year. Zhu Chunhua said that this is mainly the result of a combination of factors such as NJES's entire industry chain layout model, high degree of autonomy of core components, and scale effects.

The autonomy rate of core components of NJES robots is as high as 80%. Under the layout mode of the whole industry chain, NJES has strong cost control capabilities. As for the scale effect, this is the iron law of reducing costs and increasing efficiency in the manufacturing industry. At present, NJES has become the largest domestic company in China's domestic shipments.

If you compare NJES's gross profit margin in recent years with the "four major families", it is not difficult to find that NJES's gross profit margin is higher than that of KUKA and ABB, and comparable to Yaskawa, and strives to get closer to FANUC. In fact, one of the important reasons for FANUC to maintain high gross profit is also its production model in the whole industry chain.

In a sense, NJES and FANUC have similar development paths. Both started with CNC systems, and then FANUC developed into the three major business synergy of industrial automation, machine tools, and robots; NJES cultivated core automation components and motion The two core businesses of control systems, industrial robots and intelligent manufacturing systems. This synergy has further brought about economies of scale, reduced R&D and manufacturing costs, improved profitability, and enhanced their ability to withstand market risks.

Unlike FANUC's general market strategy, NJES is taking the general market + segmented market development route. Zhu Chunhua told Hay Think that NJES`s performance increase in 2020 is mainly due to the early cultivation of market segments. At present, Estun is the industry leader in the bending, photovoltaic, and die-casting market segments, with a market share of more than 70% in the bending field and more than 90% in the photovoltaic typesetting field. In addition, this year`s 3C, lithium battery, Industries such as smart packaging have also contributed significantly to Estun's performance, driving the company's large shipments of six-axis robots and SCARA robots.

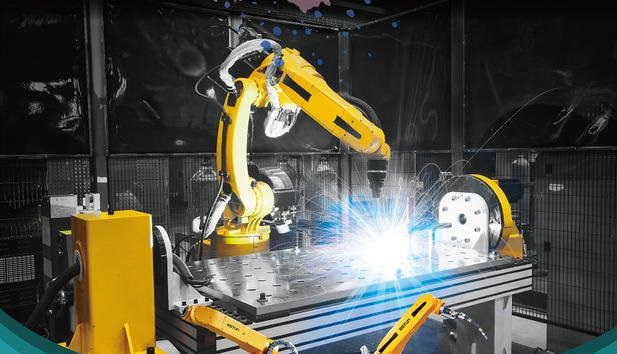

What cannot be ignored is the rapid growth that NJES has achieved in the welding field this year. In this regard, Estun stated in the 2020H1 performance report: “During the reporting period, the company completed the merger and reorganization of the German robotics company, which has a positive impact on the growth of the company`s performance.” According to Zhu Chunhua, NJES from 2020 to present The shipment volume of welding robots also exceeded 1,000 units, achieving rapid growth.

The synergy effect with the German Robotics Technology Company is gradually emerging. On the one hand, NJES has achieved the integration of the products of both parties by grafting the German Robotics Technology Company`s century-old welding technology. The NJES welding robots have been greatly improved in terms of speed, accuracy, and performance. Production efficiency has increased by 30% on the original basis; on the other hand, the "dual brand" strategy implemented in the field of welding robots will also help NJES to "completely encircle" the welding market.

The German Robotics Technology Company acquired by NJES is a global leader in the field of robotic welding, especially in the field of medium and heavy plate welding, with a large market share and world-class customers. The upcoming arc welding robot will target the high-end market of medium and thin plates.

For NJES, whether it is bending, photovoltaic or die-casting and other market segments, the position of the industry leader is basically stable. To enter the world's first camp, it will inevitably move toward the automotive field to compete with international giants. The automobile manufacturing industry not only represents the degree of industrial development of a country, but entering the automobile OEM is a symbol of the full rise of domestic industrial robots.

Because automobile production requires relatively high tempo, accuracy, and reliability, there are obvious brand barriers for industrial robots in automobile OEMs. In order to penetrate into automobile OEMs step by step, "curve entry" is currently NJES's main response strategy: firstly, open up the situation among auto parts manufacturers and first and second-tier suppliers, and secondly enter domestic automobile manufacturers with stable and reliable products and high cost-effective advantages Medium; finally entered the foreign brand automobile OEM.

Zhu Chunhua said that China's industrial robot market has a huge space, and NJES robots will continue to maintain a momentum of rapid growth in the next few years. NJES can quickly respond to market customer needs and provide timely and complete pre-sales, mid- and post-sales services; secondly, the company will actively strengthen strategic cooperation with upstream and downstream customers in the industry, and build the NJES industrial ecological chain through technical and business cooperation models.

Toward the first camp of global industrial robots

To enter the global camp, we must be good at using global resources to "arm" ourselves. At present, US micro-servo drives, human-machine collaborative intelligent robots and medical rehabilitation robot manufacturers, well-known motion control brands, the United Kingdom, and German welding robots have all become NJES "generals" to help them achieve global business expansion and resource integration.

Not only that, on July 24, 2020, NJES released a plan for a fixed increase of nearly 1 billion, and the National Manufacturing Transformation and Upgrade Fund, General Technology Group, and Xiaomi Yangtze River Industry Fund have all entered. Zhu Chunhua believes that this is not only a recognition of NJES's strength, but also a long-term optimistic view of NJES's future development, which strengthens NJES's determination and confidence in becoming a world-class robotics company. More importantly, the above funds and companies' equity in NJES will form a huge synergy effect. With the full integration of major resources, it will greatly enhance the brand power of NJES and help NJES robots penetrate into more super factory applications.

Of course, external resources are only one of them. NJES is also deeply aware of the objective gap between the company and the world's first-tier companies. Under this central goal, in the next three to five years, NJES will first fill up product gaps, increase R&D and investment in product performance and reliability, and improve product quality through process upgrades, equipment investment, and process system improvement. Customers use it well and feel at ease.

At the same time, build the NJES robot industry ecological chain, deepen cooperation with upstream and downstream enterprises in the industry, create a closed-loop ecological chain of core components, ontology, and system integration. With the help of industrial power, "one city, one pool" is steadily and steadily, and the transition from quantitative change to qualitative change is achieved; Use the accumulated resources to complement each other and refine the core technology moat.

Based on the existing methodology, Zhu Chunhua stated that by 2021, NJES will maintain a high-speed growth trend, make full progress toward the sales target of 10,000 units, and be the first to enter the domestic 10,000-unit club; in 2022, it will penetrate into more segments to drive product shipments. , Until entering the world's first camp.