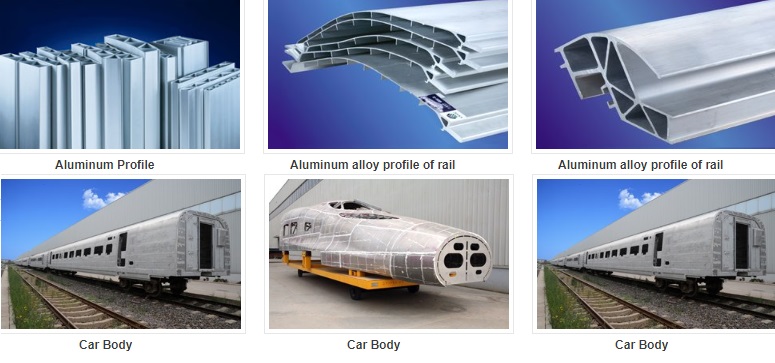

With the continuous development of China's rail transit industry, rail transit has become the main mode of transportation for people’s daily travel. The body parts are one of the most important components of rail transit vehicles, mainly composed of the underframe, the left and right side walls, and the front and rear sides. The end wall and ceiling are composed of six modules. The aluminum alloy car body parts absorb the lightweight design concept, adopt the thin-walled hollow aluminum alloy profile design scheme, and combine the integral welding process to better consider the relationship between strength and rigidity.

Compared with the traditional carbon steel and stainless steel body, the aluminum alloy car body has obvious advantages in weight. The density of aluminum alloy material is only 1/3 of that of steel. Each car can reduce the weight by about 1 ton, which can significantly reduce operating energy consumption. , It can save 10,000~15,000 kilowatt-hours of electricity each year, thereby improving the operation capacity of vehicles; in terms of anti-corrosion and corrosion resistance, the aluminum alloy material itself is an environmentally friendly, anti-corrosion material, and can be recycled and can be used on its surface in a natural state. A dense oxide film is formed. Even if the anti-corrosion protection of the car body surface is peeled off or damaged, the corrosion resistance of the car body can be guaranteed. The service life of the car body can reach more than 30 years; in terms of air tightness and appearance Above, the aluminum alloy car body is an integral welded structure, which has better airtightness, and its appearance is more beautiful after the same surface painting treatment. Due to the outstanding advantages of aluminum alloy car body structure, the amount of domestic and foreign rail transit car body products is increasing year by year.

SDNW Lightweight Materials and Equipment Technology Group is mainly engaged in the production and processing of thin-walled hollow aluminum alloy profiles and aluminum alloy car body parts for high-speed rail, subway and other large-scale rail transit industries. It has a number of modern large-scale aluminum alloy extrusions with international advanced levels Production line, automatic welding and CNC machining production line, with an annual production capacity of 3,000 car body modules. The production adopts the international rail vehicle welding standard EN 15085-2 CL1. It is a strategic cooperative enterprise of famous rail vehicle transportation companies such as CRRC, Germany's Siemens, and France's Alstom.