ZCJT intraocular lens technology group focuses on R&D and manufacturing of artificial synthetic crystal materials, advanced functional composite materials and superhard materials and products.

ZCJT has a team of technical talents with national experts as the core, and has strong scientific and technological development capabilities. The preparation technologies of nonlinear optical crystals, infrared optical crystals, scintillation crystals, glass ceramics, transparent ceramics, synthetic diamond catalyst alloy powders, etc. have reached the international, advanced or domestic leading levels respectively. ZCJT has undertaken hundreds of national scientific research projects, the national "863" plan, the National Natural Science Foundation of China and other scientific research projects, and has been responsible for drafting nearly 100 national and industry standards. He has won two national first prizes for scientific and technological progress, five second prizes, and two DuPont scientific and technological innovation prizes, and nearly a hundred awards at ministerial level and above, and has dozens of domestic and foreign patents.

The main products currently include: catalyst alloy powder and composite powder for synthetic diamond, hot-pressed magnesium fluoride products, hot-pressed zinc sulfide products, CVD zinc sulfide products, CVD zinc selenide products, silicon nitride ceramic products, and processable ceramic products , Ultra-low expansion glass ceramic products, sodium iodide (thallium doped) scintillation crystals, molten mica ceramic products, etc.

Transparent Magnesium Aluminum Spinel Ceramics

Transparent magnesia-aluminum spinel ceramics, a two-color material with excellent performance, were reported in the 1980s, but China has not yet produced it, and technical research is also very difficult. In response to the urgent national strategic demand for new materials, Academician Dr. Huang of the ZCJT R&D team, as the technical leader, communicated closely with customers, proposed spinel scientific research projects, and led the way when China`s research and development basis and related materials were blank. The team has successively solved a series of key technical problems such as high-purity ultra-fine powder preparation and engineering technology, spinel ceramic sintering, and the preparation technology has reached the international advanced level, breaking the monopoly of foreign technology and products, and realizing domestic application.

For his outstanding contributions in the field of magnesia-aluminum spinel ceramics, Academician Dr. Huang is not an exaggeration at all. Academician Dr. Huang has undertaken and participated in more than 20 scientific research projects such as the National Science and Technology Research Project, the National 863 Project, the National Natural Science Foundation of China, and the National Key Research and Development Program.

The scientific research project of Dr. Huang's R&D team has been successfully completed, but there is still a long way to go before industrial applications. This not only requires product consistency and stability, but also a strict evaluation cycle. The research and development team of Academician Dr. Huang quickly promoted the transformation of spinel results. First, the spinel baffle was finalized and mass-produced, and then the spinel ball cover was finalized, which produced good economic and social benefits. Facing the market, the research and development team of Academician Dr. Huang took the lead in applying transparent polycrystalline spinel to the light-emitting substrate of large-screen rear-projection TV, and formed scientific research results with independent intellectual property rights.

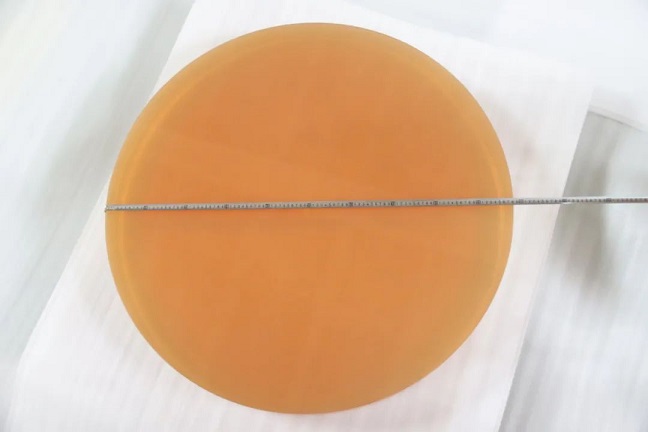

Ultra-low expansion glass-ceramic

Ultra-low expansion glass-ceramic with 1000×120mm diameter

Since the establishment of the ultra-low-expansion glass-ceramic project team in 2001, due to high technical difficulty, high investment, and difficulty in application, the research and development team of Academician Dr. Huang, as the vice president of science and technology and the leader in charge, has seen the prospects of materials. After nearly 20 years The technological innovation and accumulation of the company has achieved a breakthrough in the production process of ultra-low expansion glass-ceramics. The high-quality glass-ceramics developed by the company have passed the assessment of laser gyro users and have achieved full import substitution. In April this year, the mass production qualification rate of rice-grade glass-ceramics reached 90%, which enabled ZCJT to have the mass production capacity of meter-grade glass-ceramics and the ability to compete with foreign manufacturers.