SXLS Super Alloy Technology Group focuses on the field of aero engines and gas turbine hot end components. The company is mainly engaged in the research and development, production and sales of superalloys, and the research and development, production, sales and maintenance services of single crystal directional turbine blades for aircraft and gas turbines.

SXLS relies on the unique rhenium and molybdenum metal resources of the parent company "Refining Aviation", adopts mature single crystal blade technology and manufacturing technology, and integrates the management models of Chinese and Western aerospace manufacturing companies to create an international and domestic aerospace standard Turbine blade research and development and production enterprises.

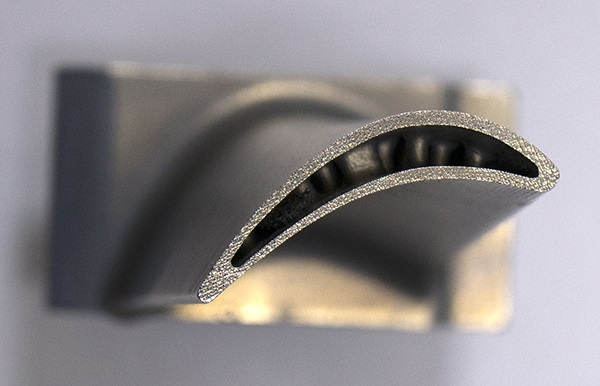

The company is committed to the research and development and manufacturing of rhenium and molybdenum ultra-high temperature alloy materials and single crystal turbine blades. It has built a complete industrial chain integrating high-temperature alloy smelting, blade precision casting, blade machining, and surface treatment, and has successfully developed and produced A variety of directional, single crystal turbine blades and high-temperature alloy materials.

Superalloy

The company can provide customized nickel-based equiaxed crystal, oriented crystal and single crystal superalloy blades and components.

Casting superalloy base material

Rhenium

Rhenium (Re) is a refractory metal with high melting point, high strength, good plasticity and excellent mechanical stability. Because there is no brittle critical transition temperature, it has good creep resistance under high temperature and rapid cooling and heating conditions. Variable performance, so it is especially suitable for ultra-high temperature and strong thermal shock environment. Due to the excellent physical and chemical properties of the metal itself and its alloys, rhenium can be widely used in fields such as national defense, aviation, aerospace, nuclear energy, and electronics industry.

Aeroengine super heat-resistant alloys can be divided into three categories according to the matrix material: iron-based, nickel-based and chromium-based. According to the production and processing methods, it can be divided into deformed superalloys and cast superalloys, which are mainly used for the manufacture of high temperature resistant materials for aero engines.

Among them, nickel-based single crystal superalloys have excellent high-temperature properties and are currently the main materials for manufacturing advanced aero-engine and industrial gas turbine blades. The addition of metal rhenium is an important factor in improving the temperature resistance of single crystal superalloys, and it also significantly improves its durability and environmental resistance.

Aviation parts

The main products are aircraft and engine parts, including the aircraft's wing leading edge surface, engine-related components, take-off and landing equipment, fuel pump covers, wing stringers, wing skins, spars, super-large wing skeletons and other core components. Products are widely used in wide-body/narrow-body commercial airliners, helicopters, engines, other aircraft, industrial products, etc. Major customers include Airbus, Rolls-Royce…