Recently, China`s leading titanium alloy material technology company, SXBT Titanium Material Technology Group, and China State Power Investment Corporation have successfully signed the "National Demonstration City Joint Declaration of Enterprise Cooperation Letter of Intent" project and the first batch of titanium material procurement contracts, marking SXBT's official entry into the new titanium Material application field.

The project actively promotes the construction of fuel cell vehicle industry demonstration city clusters in Beijing-Tianjin-Hebei, Hubei, Zhejiang and other regions, and provides core technical support for the development of relevant basic materials and key components and the development of the national fuel cell vehicle industry.

As early as 2017, the SXBT Titanium Materials Research Institute and related research institutions established a hydrogen energy project team. According to China's new energy development strategy and future market demand, they began to develop titanium technology for hydrogen fuel cells. During this period, the SXBT project team closely focused on the performance requirements of the hydrogen fuel cell metal bipolar plate, actively overcoming difficulties and repeated trials. In October 2019, the titanium bipolar plate was successfully applied on the first new energy hydrogen bus, and it fully met the pre-design requirements after later testing. On September 27, 2020, the hydrogen fuel cell product launch conference was held. SXBT was invited to participate in the conference and focused on promoting titanium bipolar plate products.

About Titanium Bipolar Plate

Titanium and titanium alloys have low density, high specific strength and excellent corrosion resistance in acidic environments, and have high application value in hydrogen fuel cell bipolar plates.

As an important part of PEMFC, the bipolar plate accounts for more than 70% of the weight of the stack and about 50% of the volume, and its cost is about 30% to 50% of the battery cost. Bipolar plate materials are mainly divided into three categories, namely graphite bipolar plates, composite bipolar plates, and metal bipolar plates.

Among them, graphite bipolar plates have light weight, good corrosion resistance, excellent electrical and thermal conductivity, but are brittle, and high flow field processing costs; composite bipolar plates have excellent forming properties, high mechanical strength, but poor electrical conductivity, and processing Higher cost; In contrast, metal bipolar plates have thin thickness, excellent electrical and thermal conductivity, high mechanical strength and good gas insulation, which is beneficial to the improvement of battery specific power density. In addition, the metal material processing technology is mature and can be stamped and die-cast The high-precision and complex flow fields are processed by methods such as laser forming, and it is easy to realize the quantitative production of electrode plates, which has become the mainstream bipolar plate material for hydrogen fuel cells.

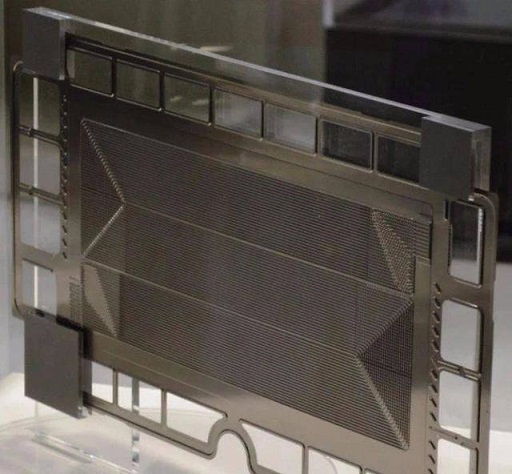

Metal bipolar plate materials are generally divided into stainless steel, aluminum alloy, and titanium alloy. Among them, the corrosion resistance of titanium in the PEMFC environment is better than that of stainless steel and aluminum alloy, and its specific strength is high, which can further reduce the weight of the plate and improve the PEMFC Specific power density. For example, the Japanese Toyota MIRAI fuel cell vehicle uses titanium as the bipolar plate material and adopts a 3D mesh flow field structure design. Compared with the stainless steel DC channel flow field bipolar plate, its stack mass power density and volume power density have been greatly improved. Promote.

Currently, two important issues restricting the commercialization of hydrogen fuel cells are cost and durability. The plate material, flow field processing and plate coating preparation process determine the cost of the bipolar plate to a certain extent.

Graphite and carbon-based composite materials can no longer meet the requirements of hydrogen fuel cells in performance, and metal materials have now become the mainstream materials for hydrogen fuel cell bipolar plates. In addition, high power has always been the pursuit goal of hydrogen fuel cells. Titanium and titanium alloys in metal materials have low density and high specific strength. They have excellent corrosion resistance in hydrogen fuel cells and can significantly reduce the weight and volume of the bipolar plate. Significantly improve the mass specific power and volume specific power of the battery, and the corrosion products produced by titanium and titanium alloy during long-term service operation are less toxic to the proton exchange mode and catalyst, which is beneficial to improve the stability and durability of battery operation.

The metal carbon/nitride and amorphous carbon coatings prepared on the surface of the titanium bipolar plate have superior comprehensive performance and high research and application value. However, these coatings are prone to pinhole defects, so the main goal of current research is to improve Coating compactness, film base bonding strength and coating surface conductivity. In addition, the coating should also have good hydrophobicity to promote the discharge of water produced by the reaction. To meet these comprehensive properties, higher requirements are put forward for the structural design and organizational composition of the coating.

The composite and nanostructure of the coating structure can improve the compactness, corrosion resistance and conductivity of the coating to a certain extent, and enhance the service stability and reliability of the titanium plate, which is the main direction of future development.