On November 30, AHEK Display Material Technology Group officially launched the construction of UTG (Ultra Thin Glass) factory. It is expected that the new factory will be mass-produced in May next year. The monthly production capacity of the first phase is 300,000 pieces of folding screen glass cover.

AHEK recently exhibited 7.2-inch folding ultra-thin glass (UTG) and 17.7-inch folding ultra-thin glass curling samples. The former has a thickness of 30 microns and a minimum bending diameter of 3mm. The minimum bending diameter is expected to reach 2mm in the third quarter of 2021; The latter has a thickness of 100 microns and can achieve dynamic crimping.

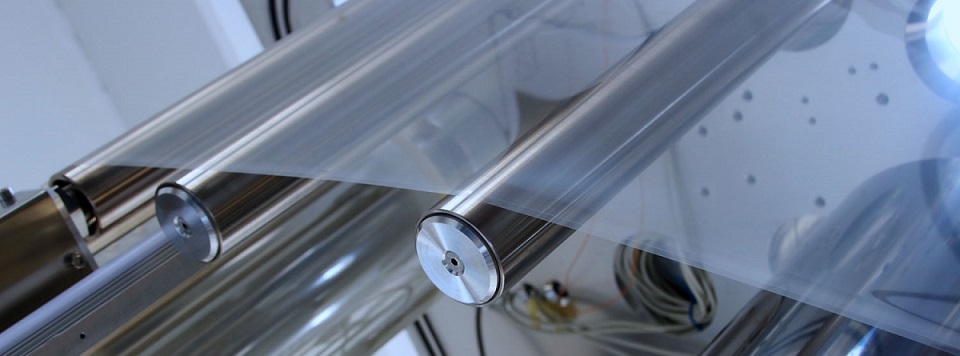

Zhou Haoyu, CTO of AHEK, introduced that the foldable ultra-thin glass process can be divided into four parts: mother board cutting, side treatment, surface treatment, and assembly inspection. Among them, the two parts of mother board cutting and side treatment cannot guarantee the glass edge. Flattening can easily cause the glass to break. AHEK uses the S-Cutting process to make the edge of the glass more flat; the surface treatment part needs the flexibility of the strengthened glass, otherwise the glass is easy to break during the bending process. AHEK uses a strengthened film to fill the original surface of the glass The micro-crack improves the toughness of the glass.

At present, there are mainly two solutions for foldable screen cover, UTG and CPI (transparent polyimide), which one is better? Zhou Haoyu believes that although both CPI and UTG have crease problems during the application of folding screen mobile phones, UTG has more advantages than CPI. UTG has higher visible light penetration, module displacement can be reduced by 10%, OLED panel stress is reduced by 30%, and flatness after bending is 50% lower.