China's leading ultra-precision parts manufacturer: SDHY Precision Technology Corporation is committed to the research and development of ultra-precision mirror machining technology, especially the development of anti-fatigue technology. After nearly ten years of research, it successfully launched ultrasonic rolling metal parts Technology, this technology completely surpasses the European ultrasonic shot peening technology.

The first partner is the French energy and transportation equipment giant Alstom

In 2008, Alstom produced a 130-ton nuclear power plant key component, which was not met by the customer. It needed further processing and adjustment of technical parameters to improve the surface finish and hardness of the components. Alstom’s technical engineers learned that SDHY can increase the fatigue life of formed parts by 100 times, while Alstom’s technology can only increase it by 10 times. Using SDHY's processing technology to reprocess the parts and finally meet the customer's technical requirements.

If the cooperation with Alstom has made SDHY famous, it took three years for SDHY to successfully replace Germany's Siemens with the leading HZQL steam turbine manufacturer in China, and the ultra-precision bearings processed by SDHY's processing technology have won better than Siemens. The test data made everyone in the steam turbine factory give their thumbs up. Finally, in 2006, ZHQL replaced all the Siemens manufacturing processes with SDHY.

Now SDHY has more than 200 related patents, and its customers have expanded to 1,200 cooperative companies including Apple and Embraer. Its products and technologies have been used in various industries such as aerospace, rail transit, machinery manufacturing, energy and power, and are high-end equipment for China and internationally. Manufacturing provides a new cutting-edge processing technology.

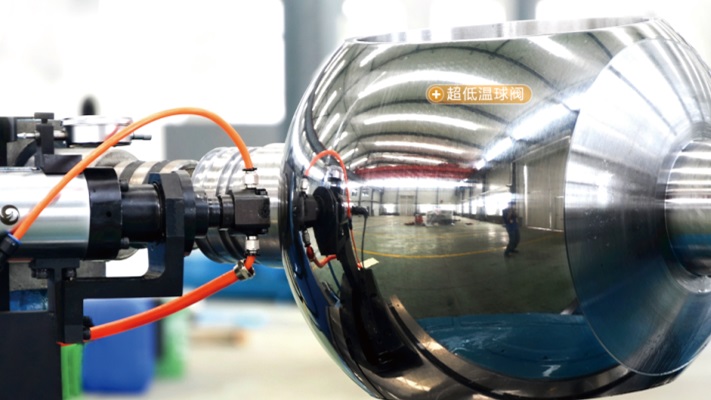

Ultrasonic rolling of metal parts is equivalent to adding an "ultrasonic rolling" process in the traditional machining processes-turning, milling, planing, and grinding. The purpose is to improve the life and reliability of precision parts. Ultrasonic rolling is to first use equipment to vibrate the part at ultrasonic frequency. By continuously hitting the part to shape it, then using the rolling tool to change the size and shape of the part, and finally the original uneven surface of the part is "cut peaks and fills valleys." ".

In 2019, SDHY and the Chinese Academy of Engineering jointly developed an aero engine bearing. After testing, the roughness value of the processed bearing reached 0.05 to 0.2 microns, and its fatigue life was 22 times that of the German FAG aviation bearing, which solved the problem of Chinese aero engine A key technical issue in R&D.