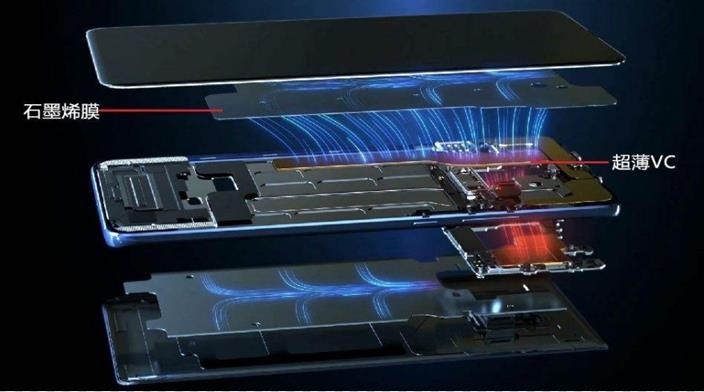

On February 13, 2020, Xiaomi used a pure online conference to lead the industry trend in the 5G era, instantly bringing industry technologies such as gallium nitride and WiFi6 to life. Xiaomi Mi 10 is a weathervane in the 5G era, and its influence does not stop there. At the Xiaomi 10 launch conference, Lei Jun said that powerful performance will bring heat dissipation problems. Xiaomi Mi 10 uses a "a bit exaggerated" three-dimensional heat dissipation structure, adding the largest area VC heat-dissipating plate on the market at the same time, while using thermal conductivity so far Graphene, the highest carbon material, dissipates heat from core components such as processors, motherboards, and batteries. At present, there are very few related companies engaged in the development and production of chemical method graphene thermal film. GDMR Graphene Technology Co., Ltd. invested by Xiaomi Industry Fund is currently the only company in China that covers the production of chemical method graphene to high performance thermal film New materials technology enterprise. Xiaomi not only invested in this "black technology" company, but also used the company's production of heat dissipation materials for 5G high-end flagship mobile phones.

Graphene is a cutting-edge new material discovered at the beginning of this century. It has the thickness of a single carbon atom layer and has the best thermal conductivity, electrical conductivity, strength, and toughness among all known materials, so it has attracted widespread attention in the electronics industry. At present, the methods that can mass produce graphene are mainly mechanical methods and chemical methods. Among them, the mechanical method mainly strips graphene from graphite by physical means such as grinding and ultrasound. The number of layers is uneven, the performance is average, but the technical threshold is low and the cost is low. At present, most of this type of graphite is on the market. Ene. The chemical principle is to use a strong oxidant to uniformly insert between the graphite layers and expand to separate the graphene layers. Therefore, the number of layers is high, the uniformity is high, and the performance is good, but the mass production technology is very demanding. Only a few companies in the market can Mass production.

With the large-scale popularization of 5G technology and the improvement of chip technology, mobile phones are developing towards high integration, thinness, intelligence, and multifunction, and have higher heat dissipation requirements. Originally, most mobile phones used artificial graphite sheets to conduct heat. It was imported polyimide film as raw material and obtained by high temperature graphitization. Due to the limited thickness of the polyimide film, the thickness of the artificial graphite sheet is limited. The thickness can only be increased by multi-layer stacking of adhesive to meet higher heat dissipation requirements. The thickness and cost are greatly increased, and the presence of glue is greatly reduced. The thermal conductivity. In this case, there is an urgent need for higher performance thermally conductive materials on the market. As the best thermally conductive graphene, the thermal film made of it has an unstoppable penetration in the field of smart phones.

Graphene, which is thicker by mechanical methods, has lower performance, and the thermal conductivity film made by high-pressure molding has poor toughness and many defects, which cannot meet the increasing demand for thermal conductivity. The thermal conductivity of graphene thermal conductive film of chemical method can reach 2000W / m · K or more, which is higher than that of artificial graphite sheet and mechanical graphene thermal conductive film, which is much higher than that of metal heat sink, and the thickness can be customized without adhesive. It is an advantage that artificial graphite sheet is hard to reach. It also has advantages not good in heat pipe / soaking plate, such as good flexibility and low cost. Therefore, chemical graphene thermal conductive film will greatly replace the current mainstream artificial graphite sheet in the future. The combination of chemical graphene thermal film + heat pipe / soaking plate and multiple heat dissipation materials will be a long-term development trend in the future.

GDMR Technology Co., Ltd., established in 2015, is one of the only companies in the graphene industry engaged in the development and production of chemical method graphene thermal conductive films. R & D team consisting of more than 20 doctors and masters at home and abroad, mainly engaged in the research and development, testing and production of graphene and its products. Since its establishment, the company has more than 30 graphene-related patents, and has launched a number of graphene application products in cooperation with upstream and downstream companies in the industry chain.

After years of intensive research, GDMR technology has successfully tackled high-performance graphene thermal conductive films, from the industrial production, dispersion, and film formation of chemical graphene to the entire production link of thermal film sintering, die cutting, and processing. Master special processes to make graphene Key technologies such as orientation alignment, composite high-temperature treatment to remove defects, and thickness control without adhesive. At the same time, GDMR technology cooperates with Yuntianhua Group, a well-known domestic chemical company, to build a large-scale production of the entire industrial chain from raw materials to die cutting, and to recycle and use a large amount of waste liquid produced in the production process, greatly reducing costs and environmental protection To achieve circular economy, the product can be directly used by mobile phone terminal manufacturers to meet the heat dissipation needs of 5G terminal products.

According to the IDC report, global handset shipments in 2019 were 1.371 billion, and global handset shipments are expected to reach 1.542 billion in 2020-2023. The penetration rate of 5G mobile phones is as high as 25%, and the market for graphene thermal conductive films is expected to reach US $ 2.3 billion. In addition, graphene oxide is widely used in textile fibers, heavy anticorrosive coatings, biomedicine and other fields, and the market size of single fields is as high as billions to tens of billions.

The Xiaomi Industry Fund has invested in GDMR technology in 2019, using upstream and downstream cooperation in the industrial chain to support the development and production of GDMR technology graphene products.