SXZG Stainless Steel Pipe Technology Group, is committed to researching, developing, manufacturing and selling: the high-performance alloy materials pipes and fittings used for energy engineering including nuclear power, thermal power, petroleum, coal, chemical engineering and natural gas and others; the pipes and fittings with high-performance, high corrosion resistance applied to gas and liquid conveying pipelines related to urban drinking water, food sanitation, pharmacy, electronic industry, environmental engineering, biological engineering, marine engineering and ultra cryogenic engineering and so on; the pipes and fittings resistant to high temperature and high pressure used for decoration & mechanical structure, boilers, heat exchangers and condensers.

The materials we use to process pipes and fittings can cover 304, 304L, 304H, 316L, 321H, 347H, 317L, 309S, 310S, S31803, S32205, KY704 and etc. We can produce all kinds of different grades of stainless steel seamless pipe,welded pipes , alloy welded pipes, composite steel welded pipes and special shaped steel welded pipes and others with outside diameter from 8mm to 3048mm and with wall thickness from 0.5mm to 60mm.

Product categories

Industrial Liquid Conveying Stainless Steel Pipe

Large Diameter Industrial Stainless Steel Pipe

Super-Large Diameter Industrial Stainless Steel Pipe

Stainless Steel Tube For Boiler, Heat Exchanger & Condenser

Food & Hygiene Grade Tube

Welded Pipe For Coal Mine

Decorative Tube For Mechanical

Duplex Stainless Steel Welded

Stainless steel Knowledge

Stainless Steel Pipe Weight Calculation Table

Chemical Composition Table Of Common Stainless Steel

Mechanical Property Of Common Stainless Steel

International Stainless Steel Comparison Table

Best-selling Products

Industrial Liquid Conveying Stainless Steel Pipe-Industrial Pipe

Industrial Liquid Conveying Stainless Steel Pipe-Marine Pipe

Industrial Liquid Conveying Stainless Steel Pipe-Petrochemical Pipe

Industrial Liquid Conveying Stainless Steel Pipe-Pipe For Anti-Corrosive Liquid Delivery

Industrial Liquid Conveying Stainless Steel Pipe-Corrosion Resistant Alloy Pipe

Industrial Liquid Conveying Stainless Steel Pipe-Stainless Steel Welded Pipe

Super-Large Diameter Industrial Stainless Steel Pipe-Liquefied Natural Gas (LNG) With Large Diameter And Thick Walled Pipe

Strengthen The Spiral Welded P-Reinforced Bar Spiral Welded Pipe For Coal Mine

Straight Welded Pipe-Longitudinally Welded Pipes For Coal Mine

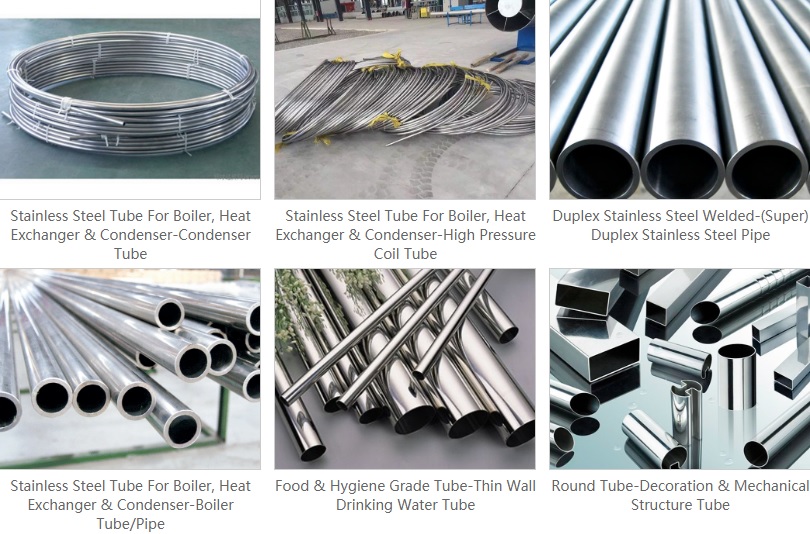

Stainless Steel Tube For Boiler, Heat Exchanger & Condenser-Condenser Tube

Stainless Steel Tube For Boiler, Heat Exchanger & Condenser-High Pressure Coil Tube

Duplex Stainless Steel Welded-(Super) Duplex Stainless Steel Pipe

Stainless Steel Tube For Boiler, Heat Exchanger & Condenser-Boiler Tube/Pipe

Food & Hygiene Grade Tube-Thin Wall Drinking Water Tube

Round Tube-Decoration & Mechanical Structure Tube

…

The company is one of the largest enterprises that can produce the most complete varieties and specifications of stainless steel welded pipes. The annual production capacity of stainless steel welded tubes, pipes is about 150,000 tons.The completion and operation of the project will completely change stainless steel industrial welded pipes market mainly monopolized by southern manufacturers and provide a new supply base for the market in North China.

The company owns the international advanced production line of JCO large-caliber single forming process, full automatic continuous molding production line of FFX longitudinal welding process, continuous molding production line of spiral welded process. It possesses the CNC manipulator automatic machining center for shearing the large sheet, 3600-ton CNC molding unit, 1600-ton two-plane linkage forming unit, nine full-ring frame CNC pipe tack-welding machine, the digital welding equipment with laser tracking ability, full automatic solid solution furnace for large-caliber welded pipe, high-precision finishing straightening equipment, RT real-time continuous imaging detection equipment, new pollution-free pickling passivation equipment and etc. The whole production process is automatic and clean.