TWCM Precision Components Technology Group is one of the major global OEM / ODM manufacturers, also is a well-known precision MIM component manufacturers.

The company has two manufacturing bases has been built in mainland China, It to provide global customers a prompt and flexible OEM and ODM production services.TWCM is familiar by top branding computer companies for its computer barebones manufacturing, also is well-known in MIM components manufacturing industry, as one of the leading manufacturers.

From 1985, TWCM started producing computer subsystems and developed to the current scale. Today's TWCM has been leading the industry with its excellent performance, establishing a very good reputation. It manufactures its desktop, server, and notebook subsystems with good quality and large quantity. TWCM has received the Best Quality Contribution Award and the Best Long-term Partner Contribution Award by HP, the No. 1 Overall Service Operation of the Global Server OEM Manufacturer by IBM, the Best Supplier awarded by FIC, etc. All these show the best assurance of our quality.

MIM Technology Has Been Affirmed

Since 2000, It began the metal injection molding technology (MIM) research and development, and manufacturing. MIM is one of the major core business of TWCM. Over the years, It not only applied its accumulated R&D capabilities in the MIM process and product development , but also cultivate a group of professional R & D design team. A comprehensive MIM research and applications in the stainless steel, iron alloy, copper alloy and other materials has been done. It not only has the professional R & D design capabilities, but also perfections in the mass production capabilities. Especially for the stainless steel, iron alloy production capacity and quality, have received satisfaction and trusted by the world's leading branding customers!

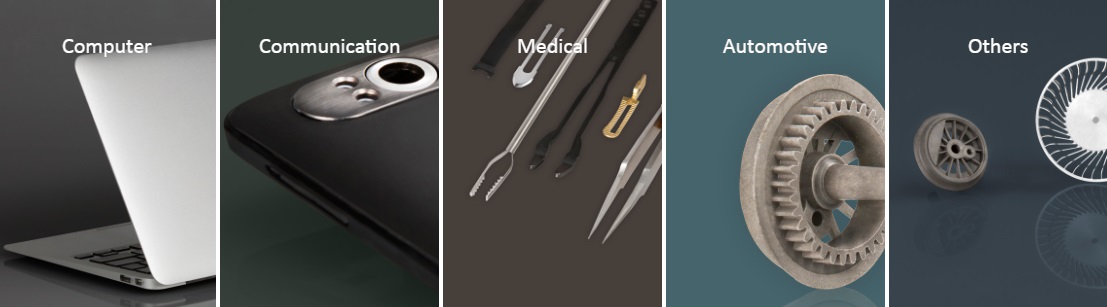

Applications