NBBW Alloy Material Technology Group was founded in 1990 and listed on the main board of Shanghai Stock Exchange 2008. After more than 30 years of rapid and healthy development, it has built nine manufacturing bases across the world.

In recent years, NBBW has completed more than 80 new material innovation projects, possessing 219 patents; it has leaded or participated in the formulation of more than 27 national standards and 9 industry standards, creating value for customers, leading the development of the industry, and promoting the progress of times.

Global Manufacturing Base

NBBW has 11 manufacturing bases over the world, including 6 manufacturing sites in China, 3 in Germany,1 in Canada, 1 in Vietnam…

Precision Alloy Strip

NBBW Alloy strip production base has state of the art production equipment, and complete testing equipment to ensure the consistency, stability and reliability of strip products.

Products:

High Strength Medium Conductivity Copper-Nickel-Silicon Strip

Copper-chromium-zirconium alloy

Copper-nickel-tin alloy

Copper-nickel-phosphorus alloy

Copper-nickel-silicon-cobalt alloy

Copper-tin-phosphorus alloy

Tin-phosphorus-zinc-copper alloy

…

More than 60 designations of strips with high-precision, high-performance alloy developed by the Company possess excellent physical properties, mechanical properties, bending performance and processing performance, as well as better tolerance control, surface finish, thermal relaxation resistance, high temperature softening performance and fatigue resistance, thus are widely used in fields such as automotive electronics, 5G communications, consumer electronics and lead frame. With professional application support capabilities, the Company provides comprehensive application solutions to continuously create value for global customers.

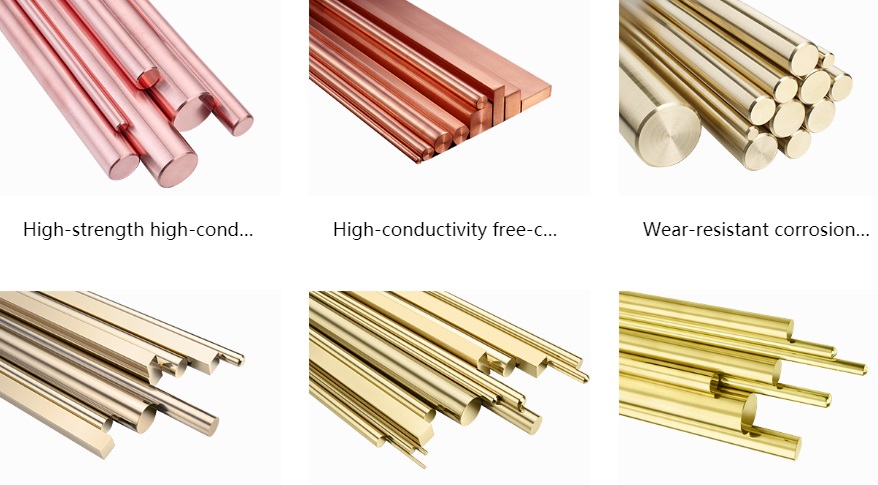

Precision Alloy Bar

NBBW has the global leading alloying and micro-structure regulation ability, It can ensure copper alloy’s uiformity, stability and reliability via high precision equipment, advanced online testing equipment and CNAS approved lab.

NBBW has developed 6 series copper alloy bars in more than 100 designations with high precision and high performance (high-strength high-conductivity alloy, high-conductivity free-cutting alloy, wear-resistant corrosion-resistant alloy, lead-free environmentally-friendly free-cutting alloy, high-speed free-cutting alloy, high-precision malleable alloy).It possesses have the ability to design special mould and has about 10,000 kinds of special moulds in different shapes and specifications in stable supply, providing customer with reliable and efficient solutions.

Products are applied in: automobile manufacturing, rail transit, shipbuilding, energy and power, engineering machinery, mining machinery, medical equipment, 5G communications, consumer electronics, new energy, high-voltage power transmission and transformation, continuously creating value for customers and boost the modern industrial development.

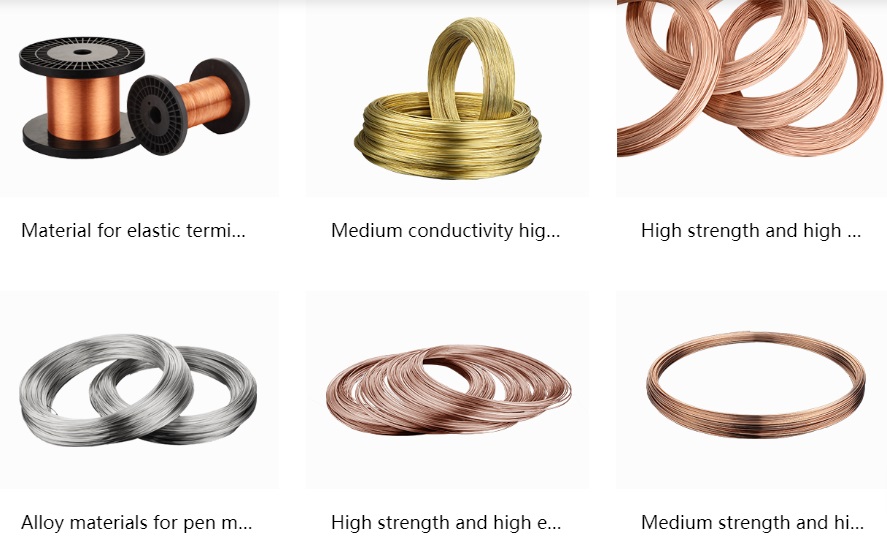

Precision Alloy Wire

NBBW`s Core technology of Precision Alloy Wire originated from the acquisition of a German precision copper alloy wire manufacturer with more than 130 years of R&D and lean manufacturing history.

It is committed to creating special alloy wires for downstream customers to lead the development of the industry. At present, it mainly serves the world top 500 enterprises and leading enterprises in the industry, and has now formed the industry-leading independent ability for high- precision mold tooling preparation, being able to provide customers with solutions for products of various shapes quickly to meet customer needs; it introduces international leading alloy wire production lines, such as full-automatic control continuous casting production line, automatic on-line induction annealing production line, strong convection bright heat treatment production line, to achieve on-line accurate control of the whole manufacturing process; Ensure the high uniformity, stability and reliability of products, improve customer market competitiveness, and boost customers in leading the development of the industry.

With a strong R & D and manufacturing platform, and "German technology to service China", the Company has developed a series of high-strength and high conductivity chromium zirconium copper alloy, high-strength and high-wear-resistant bronze alloy, medium strength and high plasticity brass alloy, high strength and high corrosion resistance Nickel Silver alloy, whole series of environment-friendly alloys, etc., high-precision alloy wires of nearly 100 designations, used in more than 20 industries such as aerospace, automobile industry , shipbuilding industry, 5G communication, consumer electronics, etc., continuously creating value for global customers.

Customer Reference

NBBW`s customers are across the global including China, the United States, Germany, France, Japan, South Korea and India.

The products and services have been recognized by many fortune 500 companies such as Siemens, Panasonic, TOTO, Samsung, Huawei and CalCom Solar.