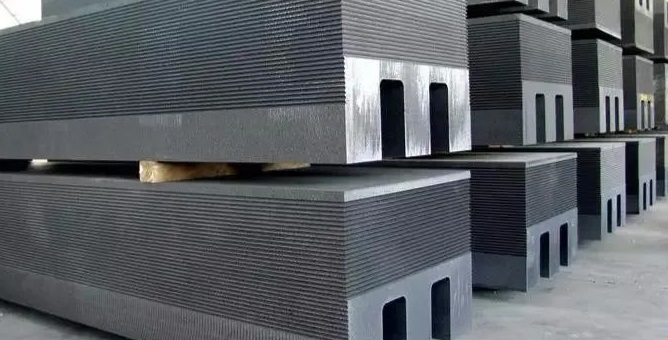

"The width of these graphitized cathodes is 770 millimeters, which is currently the world's widest super-sized graphitized cathode carbon block for aluminum. It will be applied to the world's largest 600kA ultra-large-capacity aluminum electrolytic cell." In HNWJ Graphite Technology Co., Ltd., Zhang Yonghe, the director of the processing workshop, wears a mask to disperse next to the machine. According to the customer's order, they will race a batch of graphitized cathode rough products to grow 3800 mm, 770 mm wide and 500 mm high.

"This customer completed and put into production the world's first full-series 600kA extra-large anode prebaked aluminum electrolytic cell in December 2014, which is at the international advanced level, and has a leading and demonstration role for primary aluminum smelters." Zhang Yong said, In 2002, HNWJ Graphite Technology Co., Ltd., in cooperation with Guiyang Aluminum Magnesium Design and Research Institute Co., Ltd. and Huazhong University of Science and Technology, developed the graphitized cathode production technology for aluminum with independent intellectual property rights, and built the first large-scale professional production in China. Fully graphitized cathode production line for aluminum, with an annual output of 50,000 tons of graphitized cathodes, is the world's largest graphitized cathode production base. It has successfully developed large-scale graphitized cathodes for 450kA and 500kA series aluminum electrolytic cells and 600kA The super-sized graphite cathode of the series aluminum electrolytic cell has obtained a number of technical patents, and the product quality has reached international standards. It can be produced to meet the needs of large and ultra-large pre-baked electrolytic cells.

The "graphite 'mass' cathodes" and "graphite 'chemical' cathodes" mentioned by Zhang Yong can both be used as lining materials for masonry aluminum electrolytic cells and are the main part of the cathode conductive material of electrolytic cells. Although there is only a word difference in the name, the performance and technical content of the product behind it are quite different. The "graphite" cathode has better electrical conductivity and thermal conductivity than the graphite "mass" cathode, which can significantly increase the anode current density, thereby leading to higher productivity. In addition, due to its higher corrosion resistance, The life of a graphitized cathode can generally be more than 3500 days, which is about 1/3 higher than that of a graphite cathode. Therefore, the price of a graphitized cathode of the same specification is 45% to 50% higher than that of a graphite cathode, which is exactly what it is on the market. High-end products.

"Because of the high selling price of graphitized cathodes, in the past few years, most customers were relatively keen on relatively inexpensive graphite cathodes when building electrolytic cells." Han Shuangping, deputy director of the sales department of HNWJ Graphite Technology Co. An enterprise with a 600kA ultra-large capacity aluminum electrolytic cell had once purchased 5000 pieces of ultra-large size aluminum cathodes with a length of 3800 mm, a width of 770 mm, and a height of 500 mm from Wanji Graphite in 2016. However, the first purchase of this ultra-large size graphitized cathode product for aluminum from HNWJ Graphite Technology Co., Ltd. stemmed from an accident in 2019 of the customer's company.

"When this customer company restarted the aluminum electrolytic production line after the accident, it was found that only the electrolytic cells installed with graphite graphite cathodes of HNWJ Graphite successfully completed the second start-up. Therefore, the product quality of HNWJ Graphite Technology was more recognized. We also carried out quality control technology exchanges. "Han Shuangping said that during the technical exchanges, customers heard that the graphitized cathode products of HNWJ Graphite Technology have better performance than graphite cathodes, and they decisively buried 3000 ultra-wide graphitized cathodes Order for overhaul of electrolytic cells that cannot be re-started. After the batch of electrolytic cells resumed production, after comparative tests, customers have more confidence in this graphitized cathode product.

"Compared with graphite cathodes, graphitized cathodes can greatly reduce the electricity consumption of aluminum per ton of aluminum, improve the current efficiency of the electrolytic cell, and have an important role in reducing the power consumption of aluminum electrolytic production and increasing the service life of the aluminum electrolytic cell. Looking at it, graphitized cathodes are more cost-effective. "Han Shuangping said, out of favor of product quality, this customer placed another 2,000 ultra-wide graphitized cathode urgent orders for HNWJ Graphite Technology Company before the Spring Festival this year.

"In recent years, the superiority of the company's graphitized cathodes has been gradually recognized in domestic and foreign markets. Many large domestic electrolytic aluminum manufacturers with advanced management concepts are using HNWJ graphite technology's graphitized cathode products. The purchase volume of Wanji Graphitized Cathode by Brazil, Alcoa Brasil, Venezuela Aluminium, Iceland Aluminium, Norwegian Hydro Aluminium, and Dubai Aluminium has also increased year by year. Aluminum technology continues to innovate and develop, and super-capacity pre-baked electrolytic cells have become the mainstream of new electrolytic aluminum production projects, which will bring broad market prospects for HNWJ's large-scale graphitized cathode products.