DLSH Composite Bearing Technology Group is a high-tech enterprise focusing on R&D and production of high-performance composite bearings. The company was established in 1988 and was listed on the Shanghai Stock Exchange in 2015.

DLSH's products mainly include elastic metal plastic bearings and assemblies, self-lubricating joint bearings and assemblies, bimetallic self-lubricating bearings and assemblies, copper alloy inlaid self-lubricating bearings and assemblies, and composite bearings for nuclear main pump motors. Products are widely used in hydraulic machinery, water conservancy power generation equipment, coal mills, nuclear power equipment, ships, metallurgical machinery and other fields, and are exported to the Americas, Europe, Southeast Asia and other countries. In the industry for nearly 30 years, DLSH products have been selected by customers in many national key engineering projects, such as the Three Gorges Project, Gezhouba, Ningbo Beilun Port, and National Nuclear Power Group.

Products

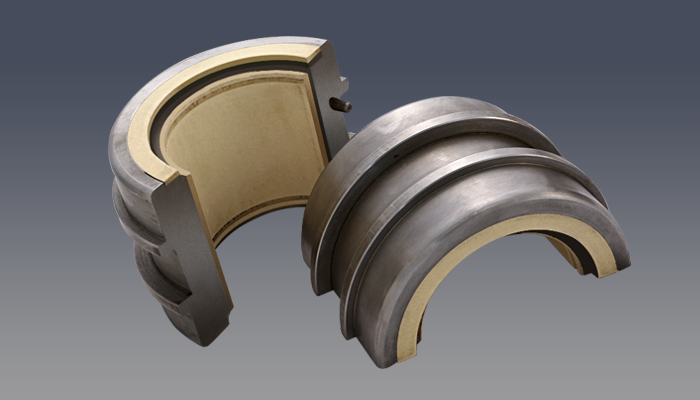

Elastic metal + reinforced modified PTFE plastic bearing and assembly

product description:

The product is a low-friction, high-wear-resistant self-lubricating composite material formed by metal wire elastic pad and reinforced modified polytetrafluoroethylene molded composite through sintering and plasticization, and is firmly combined with steel tile bases of different geometric shapes through brazing technology A new generation of plastic tiles.

Features:

①The product meets the national environmental protection requirements, has low friction, extremely high wear resistance, reliable operation, and can effectively reduce operating losses;

②It has a unique self-adjusting property, which can effectively improve the bearing condition of the bearing bush, avoid the thinning or damage of the oil film on the bush surface due to mechanical deformation and temperature deformation, and a large safety margin;

③It has a certain thermal resistance, reduces the thermal deformation of the tile base, and has a high load-bearing capacity, which is more than 20% higher than the babbitt alloy bearing;

④With excellent self-lubricating performance, the high-pressure oil jacking device can still be safely started and shut down without the high-pressure oil jacking device, simplifying the operating procedure;

⑤The product adopts the new vacuum immersion tin brazing process, the brazing bonding layer is firm and reliable, and the uniformity of the elastic modulus is improved. There is no need to scrape the tile surface for installation and maintenance.

Applications:

This product is mainly used in vertical and horizontal hydraulic generator sets, gearboxes, ball mills, water pumps, metallurgical equipment, mining machinery, ships and other industries.

Customer reference:

Harbin Electric Machinery Co., Ltd., Dongfeng Electric Co., Ltd. of Dongfang Electric Group, Alstom Hydropower (China) Co., Ltd., Toshiba Hydro (Hangzhou) Co., Ltd., Chongqing Gearbox Co., Ltd., Nanjing High Precision Gear Group Co., Ltd.

Water-lubricated bearings and assemblies

Product introduction: This product is a high-wear-resistant water-lubricating composite material formed by the combination of high-strength fibers and high-wear-resistant special engineering plastics reinforced modified polymer materials and metal wire pads, and is brazed by vacuum immersion tin to steel substrates of different geometric shapes The process is reliably combined.

Features:

It has good hydrophilicity, anti-silt and abrasion resistance;

Low friction, low power consumption, energy saving more than 15% compared with other bearings;

With self-lubricating characteristics, it can still work normally when the start and stop conditions are below the lubrication boundary conditions and the hydrodynamic water film cannot be established or the water supply system is short of water;

Large carrying capacity and certain shock absorption performance, stable and reliable operation;

Unique self-adjustment, when the bearing bush and journal are different in axis or in uneven contact caused by factors such as installation and deformation, it can be adjusted automatically to improve the force condition;

The water absorption rate is small, the size is stable, the gap is easy to adjust, and the installation and maintenance do not need to scrape the tile surface;

Instead of babbitt alloy bearing bushes, the oil supply system is eliminated and the structure is simple. Use cheap water as a lubricating medium to reduce operating costs; energy saving and environmental protection.

Applications:

FZB03GS water-lubricated bearings have been used in hydraulic turbine guide bearings, large-scale water pump bearings (including mine underground disaster relief water pumps) and other applications, and have been well received by users. The FZB3GS bearing has been successfully applied in the water lubrication conditions of the thrust bearing of a small vertical hydroelectric unit. It is safe and reliable, reduces operating costs, and is simple to maintain. It has created a precedent for the water lubrication of the thrust bearing of a hydroelectric unit.

Customer Reference:

Huanren Hydropower Station, Qingtongxia Hydropower Station, Danjiangkou Hydropower, Dongjiang Hydropower Station, Shanyuyuan Hydropower Development Company, Russia Kaya Hydropower Station, Uzbekistan Power Station, Sichuan Dongfeng, Sweden Power Station, Shanmei Hydropower Station.

Self-lubricating joint bearing and assembly

Bimetal self-lubricating bearings and assemblies

Copper alloy inlaid self-lubricating bearing and assembly

Slide bearing and assembly

Composite bearing of nuclear main pump motor

Slide and bearing assembly

Engineering plastic alloy self-lubricating slide and assembly

Engineering plastic alloy self-lubricating joint bearing and assembly

High-strength steel-based copper-plastic self-lubricating bearings

…

Over the years, we have continued to develop and innovate, upgrade technology, and update new products. Relying on the self-developed technical formula and excellent product quality, the composite self-lubricating bearings produced by DLSH are still durable under the harshest environmental conditions, providing an unprecedented long life cycle for various engineering projects. DLSH's products have the characteristics of environmental protection, safety, high performance, etc., and have become a low-carbon economy and environmentally optimized alternative product. The technical level has reached the leading domestic level and surpassed similar foreign products.

At present, the company has 36 national patents, including 24 invention patents. It has been successively rated as "High-tech Enterprise", "Provincial Enterprise Technology Center", "Self-lubricating Composite Material Engineering Technology Research Center" by relevant departments of the national, provincial and municipal governments. , Obtained ISO9001:2015 quality management system certification, and is also the drafting unit of the national product industry standard group leader.