On August 10, the super-strength continuous steel pipe developed by SXYG Petroleum Steel Pipe Technology Group successfully passed the inspection of the National Petroleum Pipe Quality Supervision and Inspection Center. This indicates that Chinese petroleum equipment manufacturing companies have mastered the world's highest strength continuous steel pipe manufacturing technology.

In recent years, as China's deep-seated oil and gas resources and shale oil and gas exploration and development efforts have increased, ultra-deep wells, high-pressure, ultra-high-pressure, ultra-long horizontal wells, workover and completion operations, etc., have proposed more and more requirements for higher strength coiled tubing. High demands. SXYG is based on the main responsibility of ensuring the main business of oil and gas exploration and development. After two years of continuous technology research and development, it finally broke through the core technology of pipe manufacturing and independently developed ultra-high-strength continuous steel pipe products.

The newly developed super-strength continuous steel pipe has a strength level of more than 1100 MPa, which is currently the highest-strength coil product in the world, with a tensile strength of 1160 MPa. According to calculations, a coiled tube with a diameter of 50.8 mm and a wall thickness of 4.0 mm can withstand a 36.4% higher tensile load than the CT110 coiled tube of the same specification, and at the same time has better plasticity. According to destructive tests, the tube burst pressure is 16.6% higher than the theoretical calculation value, and the tube collapse pressure is 16.9% higher than the theoretical calculation value. The fatigue life is also significantly better than that of low-strength coiled tubing products, and the overall performance has reached the world's leading level.

"Because the ultra-high-strength continuous steel pipe has higher strength and plasticity, it has greater penetration depth under the same conditions, and has good buckling resistance, torsion resistance and pressure bearing capacity, so it can be used for ultra-high-strength steel pipes in Xinjiang, Southwest China and other regions Deep wells, ultra-long horizontal sections of several thousand meters of shale oil and gas, and ultra-high pressure wells workover, completion, logging and other operations." said Dr. Bi, chief technical expert of SXYG.

According to Dr. Li, manager of the R&D project team, the product has a fracturing pressure of more than 100MPa and can be used in downhole operations with a well depth of 5000 to 8000 meters, providing for the development of unconventional oil and gas resources such as deep-seated oil and gas resources in China and shale oil and gas. With strong equipment support, it can greatly improve the efficiency and life of oil and gas wells, and significantly reduce the production costs of oil fields.

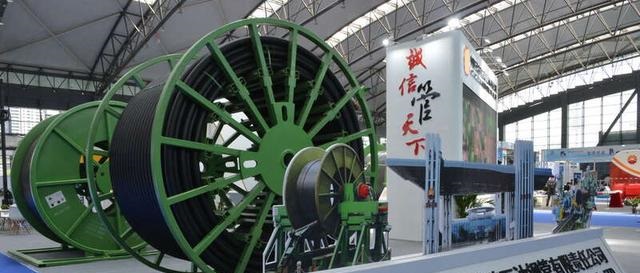

SXYG is the first company in Asia that integrates R&D and manufacturing of coiled tubing. In recent years, relying on the National Oil and Gas Pipe R&D Center, the company has continued to innovate and tackle key problems. At present, it has formed a series of high-strength steel pipes, continuous steel pipes with variable wall thickness, as well as duplex stainless steel, titanium alloy pipes, and austenitic stainless steels for oil and gas well operations under corrosive conditions. Corrosion-resistant alloy coiled tubing products have strongly promoted China to reach the world's leading level in the field of coiled tubing manufacturing.