In the broad technical spectrum of 3D printing, metal 3D printing is widely regarded as the most imaginative subdivision direction. In recent years, metal 3D printing has become a new platform for the innovative preparation of metal components in industries such as aerospace, defense, automotive, and biomedicine.

However, just like there is a long industrial chain from the lithography machine to the chip, the lack or backwardness of any link in the middle will affect the final end product. The same is true for metal 3D printing, which has global challenges that restrict its expansion into larger markets. One of the major challenges lies not in the printing equipment, but in the raw materials for printing-metal powder and wire.

Start from the upstream of the material source to solve the problem of the end of the industry chain

The quality of metal printing raw materials has a huge impact on the performance of the final 3D printed parts. For light-weight high-strength alloys used on a large scale in aerospace, automotive and other fields, how to solve the problem of thermal cracking in the 3D printing molding process is the key point for 3D printing technology to break through the market scale.

Incorporating uniformly dispersed nanoparticles into the alloy is an effective means to improve the performance of metal powder printing and to solve problems such as thermal cracking. Due to the large specific surface area of the nanoparticles, they are easy to agglomerate, so surfactants or electrostatic mutual repulsion methods are usually used to disperse the nanoparticles. However, these two commonly used methods fail in high temperature metal melt due to high temperature and the conductivity of the metal melt. Therefore, how to overcome the van der Waals force between the nanoparticles and realize their uniform dispersion in the metal melt has become an urgent problem to be solved.

For this challenge, materials scientists have given their own answers. As early as December 2015, the world's top scientific journal "Nature" published an article on "Preparation and properties of magnesium alloys containing dense and uniformly dispersed nanoparticles". First, it introduced the findings of the Chinese research team-how Choose nanoparticles that are more compatible with the alloy and disperse them evenly. Based on this discovery, the research team developed the corresponding "nanometallurgy" technology, which uses nanoparticles to change the solidification and deformation behavior of metals, thereby improving the manufacturing performance of metals. This includes the use of nanoparticles to solve the problem of thermal cracking in the 3D printing process of high-strength aluminum alloy powder.

On this basis, after two years of technical accumulation, the research team established SZMT High Performance Materials Technology Co., Ltd. in 2017, dedicated to the research, development and manufacturing of high-performance metals with nanometallurgical technology as the core. Based on a series of scientific research results, SZMT Limaite has developed corresponding nano-metallurgical processes and products. Nano-particles of ceramics, compounds and other materials are uniformly mixed into metals or alloys to "modify" and "enhance" them. , Break through the performance shackles of the original metal materials and improve its manufacturing performance.

The performance verification results are gratifying, and large-scale production is on the way

SZMT products rely on top-notch university scientific research teams, after overcoming the world problem of easy agglomeration of nanoparticles in metal melt, have successively successfully developed nano-modified super aluminum powder, nano-modified super aluminum wire, and nano-modified Super aluminum castings and nano-modified super aluminum profiles will gradually expand to nano-modified "super copper", "super steel", "super high temperature alloy" and other materials.

Regarding the choice of aluminum alloy, Dr. Liu Weiqing, CTO of SZMT, explained: “The company’s technology is a platform type. Nanoparticle dispersion technology can be applied to a variety of metals, not only magnesium or aluminum alloy. As for light weight and high strength Starting with aluminum alloy is mainly due to its large market demand and high requirements for its lightweight.” Liu Weiqing said that after aluminum alloy powder and wire products mature, they will gradually expand to aluminum alloy castings and profiles. Products with greater demand.

Regarding the current printing performance of aluminum alloy powder, a paper published in the sub-Journal Nature Communications in 2019 gave a reassuring answer. This paper, completed by the founding team of SZMT, shows that the strength of the laser-printed nanocomposite aluminum alloy reaches 1000 MPa, the plasticity exceeds 10%, and the Young's modulus is about 200 GPa.

As a result, the team broke the world record for metal printing performance and made more innovative metal 3D printing applications possible.

In addition, SZMT produced nano-modified 7075 aluminum alloy powder and nano-modified 7075 aluminum alloy wire suitable for arc additive manufacturing and electron beam additive manufacturing after 3D printing, after T6 treatment, the tensile strength can reach 540MPa or more , The elongation rate exceeds 10%, which is better than the performance of the same type of forging. At the same time, the strength of other series of nano-modified high-strength aluminum alloy powders developed by the company can reach more than 600MPa after 3D printing.

About SZMT

• SZMT High Performance Material Technology Co., Ltd. is a high-tech enterprise dedicated to the R&D and manufacturing of high-performance metals (super metals) with nano-metallurgical technology as the core.

• Relying on the R&D team led by famous foreign universities and well-known scientists, the company has overcome the world problem of the easy agglomeration of nanoparticles in the metal melt and successfully prepared super metals with uniformly dispersed nanoparticles (relevant results were published in the top international publication "Nature" on).

• SZMT is the leader of industrialized application-level nano-metallurgical platform technology. Through independent research and development of production processes, it brings epoch-making impetus to the metal industry and leads the new metal revolution in the 21st century.

• Based on a series of scientific research results, SZMT has developed corresponding nano-metallurgical processes and products. Nano-particles of ceramics, compounds and other materials are uniformly added to metals/alloys to "modify" and "enhance" traditional metals, making breakthroughs The limitations of traditional metallurgy and the improvement of manufacturing performance have led to the production of various "high-strength metals", which greatly improve the mechanical, physical, and chemical properties of traditional metals/alloys, which have been widely concerned by the industry.

• At present, the company has successfully developed nano-modified super aluminum alloy, nano-modified super aluminum welding wire, nano-modified super 3D printing aluminum powder, high-temperature super aluminum alloy, self-lubricating aluminum-bismuth bearing alloy containing nanoparticles, high-strength super copper, Various new materials such as high-temperature special super copper alloy and high-strength super magnesium alloy.

• Established strategic partnerships with many well-known aluminum alloy manufacturers in China, mobile phone brand companies, large European steel companies, large Japanese aluminum alloy manufacturers, Taiwan Gaint bicycle company and many other users, providing them with highly competitive new Material solutions.

Core Technology

Nanometallurgy

• Nanometallurgy is an emerging interdisciplinary field of materials science and engineering (especially metallurgy), manufacturing, nanoscience and engineering, studying how to design and apply nanophase (ex-situ and in-situ generation) to significantly improve processing/ Manufacturing process, micro/nano structure, and physical/chemical/mechanical behavior of metals and alloys.

• High-performance metals and alloys offer great potential to improve energy efficiency and system performance for many applications. Although the field of metallurgy has made great contributions to human civilization in the past few thousand years, traditional metallurgical methods have reached certain limits. The sudden emergence of nano metallurgy is gradually breaking the traditional metallurgical barriers and completely changing metal processing and manufacturing technology.

• With the rapid development of nanophase synthesis, addition and dispersion of large-scale manufacturing methods, the prices of metals and alloys produced by nano-metallurgy have become more and more competitive.

• Recently, the discovery of the self-dispersion and stabilization mechanism of nanoparticles in molten metal has further laid the scientific and technological foundation for the large-scale manufacturing in nanotechnology metallurgy.

• Nanometallurgy is creating exciting new processing/manufacturing spaces while pushing the range of properties of metals to meet the energy and sustainability challenges of human society.

Nano self-dispersion technology

The Matt Lee New Materials team solved the world problem of nano particles agglomerating in metal, laying a scientific and technological foundation for nanotechnology to enter metallurgical large-scale manufacturing.

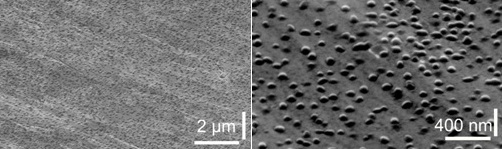

The distribution of nanoparticles in Mg+14%SiC nanocomposites (magnesium+14% silicon carbide) (left picture)

• SiC nanoparticles uniformly dispersed in the solidified magnesium alloy structure

• SEM pictures taken at a tilt angle of 52 degrees

• Demonstrated uniform distribution and uniform dispersion of SiC nanoparticles

Emerging Nanometallurgy

The emerging nano-metallurgy has become a revolutionary metallurgical platform technology in the new century, seamlessly connecting existing industrial processes and large-scale production, promoting the wide application of super metals, and leading the new metal revolution in the 21st century

Nanoparticles

Nano particles and master alloy manufacturing and large-scale production

Nanoparticle Dispersion in Molten Metals

Nanoparticles and molten metals

Solidification Processing of Super Metals

Solidification

Thermomechanical Processing

Thermoplastic processing

The problem of easy agglomeration of nanoparticles in the metal melt is solved, and super metals with uniformly dispersed nanoparticles are prepared.

1)Super Magnesium: 14% SiC nanoparticles are uniformly dispersed in magnesium alloy (Nature, 528(2015) 539-543)

2) The high content of nanoparticles in super metal and good dispersibility can give full play to the enhancement efficiency of nanoparticles.

3) Super metal has excellent room temperature and high temperature mechanical properties that cannot be obtained by traditional technology.

4) Super metal has excellent forming properties.

R&D core team

The team leader is Dr. Xiaochun Li, Chair Professor of the University of California, Los Angeles. Professor Li is a well-known expert in the field of metal-based nanocomposites.

The core members of the SZMT R&D team are all PhD and master graduates from world-renowned universities and research institutions, with deep professional knowledge and rich experience in material preparation and characterization.

Application field

1. Super aluminum-improve the mechanical properties of aluminum alloys, reduce the hot cracking tendency of aluminum alloys, especially 2000 series and 7000 series high-strength aluminum alloys, so that 2000 series and 7000 series alloys can be cast, welded and 3D printed.

2. Super copper-improve the room temperature and high temperature mechanical properties of the base copper alloy, and maintain its high electrical conductivity and high thermal conductivity; it can be used in high-speed rail contact wire, electrode, IC chip lead frame, and mobile electronic equipment.

3. 3D printing super powder-atomizing super metals (such as super copper, super aluminum, etc.) to prepare super powder, which can be used for 3D printing high-performance, complex-shaped metal parts.

Nano material advantages:

Nano-modified high-strength metals manufactured by nano-metallurgical technology are based on metals and alloys, and use high-strength metal materials that combine one or several metal or non-metal nano-level reinforcements. Nano-modified high-strength metal has the advantages of good mechanical properties, high shear strength, higher working temperature, wear resistance, good electrical and thermal conductivity, etc. Therefore, its excellent performance is used in high technology such as machinery, automation, aerospace, high-speed railway, etc. field.

Traffic, vehicles, aircraft

Nano high-strength aluminum alloy is lightweight and high-strength, has excellent weldability, processing performance and corrosion resistance, and can be widely used in transportation, such as aircraft (such as high-strength aluminum alloy plates, T-shaped materials, etc.), rail cars (such as rail In the skin of trains) and ships (such as hull floors and superstructures on decks, etc.); in the automotive field, such as all-aluminum bodies, wheels, etc.; it can also be used in various types of drones. The application of nano high-strength aluminum alloys in transportation, vehicles and aircraft can greatly reduce their energy consumption and improve their endurance.

Mobile electronics

Nano high-strength aluminum alloy is lightweight, high-strength, and good in thermal conductivity. It can be widely used in the field of mobile electronics, such as high-strength shells and middle frames of 3C products.

Sports Equipment

Nano high-strength aluminum alloy has high specific strength and specific rigidity, and can be widely used in sports equipment, such as high-end bicycle aluminum frames, baseball poles, bow arrows, climbing poles, etc.

Energy, electricity

Nano high-strength aluminum alloy is lightweight, high-strength, and good in conductivity. It can be widely used in energy and power industries, such as high-voltage cables, solar panel brackets, etc.