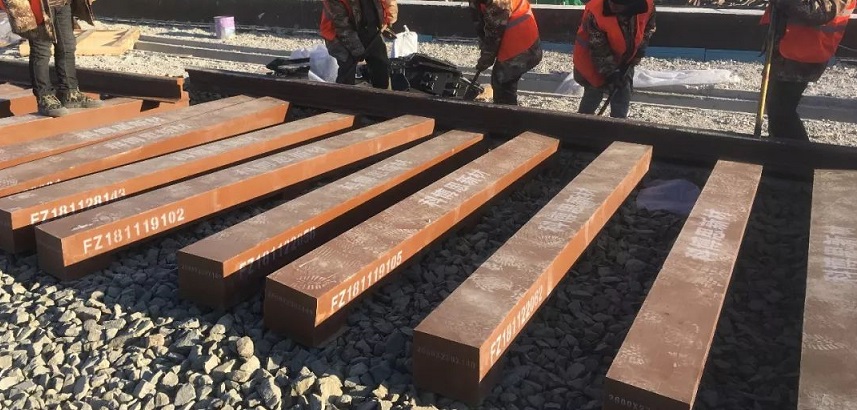

Recently, the project department of the Beijing Metro Line 13 South Yanqinghe Station of the China Railway First Bureau has completed the pre-paving of K11 600 ~ K11 972 sections. At this point, LYKBS has also overcome many difficulties such as short construction period, heavy tasks, complex product structure processing, etc., and successfully completed the supply of integrated sleepers for this project.

Beijing South Metro Line 13 Qinghe Station is a subway station mainly serving the Beijing-Zhanghai high-speed railway. It is a transfer station between the high-speed railway and the subway. The stray current generated by its special characteristics is relatively corrosive to metal materials.

Therefore, higher requirements have been placed on the insulation and stability of the sleepers selected for this line. After multiple layers of screening by the owner and the construction unit, in the end, the one-piece synthetic sleepers developed and produced by Luoyang Kebosi stood out from many manufacturers in the market.

The construction of this project is facing many problems such as tight schedule, heavy tasks, high safety risks near existing cable construction, cross-operation, etc. For this reason, LYKBS established a project special support team to actively coordinate product design, production and installation. Reliable, proactively cooperate with the design unit to optimize the design plan, complete problem solving plans, concentrate resources to ensure production and delivery, minimize production and transportation time, fully guarantee the smooth progress of the project, and have won unanimous praise from the owner and the general contractor, Also established a good start and reputation for the company in Beijing subway.

LYKBS said that the one-piece resin synthetic sleeper for rail transit developed this time is a composite material formed from continuous glass fiber reinforced polyurethane rigid foam, and has 16 independent and independent knowledge covering formula, structure, equipment, and technology. Property rights, the first time in the international scope to achieve a maximum thickness of 300mm one-time molding, completely solve the problem of synthetic cracks under fatigue loading adhesive cracking, eliminating the hidden dangers of train operation.

Compared with traditional wooden and concrete sleepers, the one-piece synthetic sleepers produced by our company have many advantages such as light weight and high strength, corrosion resistance, good fatigue resistance, long life and good insulation properties, and also solve the existing problems of traditional synthetic sleepers. Poor pull-out resistance of nails, easy relaxation of road nails, uneven resin and fiber infiltration, partial cracking of sleeper bodies, and prone to abrasion at connection parts, have been widely used in domestic and foreign railways and urban rail transit lines.