YTFX Bimetal Composite Material Technology Group is a leading manufacturer of Copper-clad Aluminum (CCA) Busbar, Copper-clad aluminium (CCA) wire, and copper-aluminum bimetal composite materials in China.

In the past 10 years, YTFX has successfully realized the “Copper-Aluminum Composite Continuous Casting Direct Forming Technology and Process” and “Composite Busbar Efficient Forming Technology and Process” through the cooperation with the team of academician Xie Jianxin, a metal material expert of the Chinese Academy of Sciences. The industrialization transformation of the company, undertaking the national “863 Program” twice, and taking the lead in drafting two national standards and one international standard in the field of continuous casting copper-aluminum composite materials: ASTM B1005.

The copper-aluminum composite conductor material developed by YTFX has a volume conductivity of 75% and a current carrying capacity of 80% of that of pure copper of the same specification. Compared with copper, the weight is reduced by 50% and the cost can be reduced by about 30%. The core advantage of YTFX is the metallurgical bonding between copper and aluminum atoms, which solves the transition problem of copper and aluminum transition. “

The main feature of YTFX’s copper-aluminum composite material is its lightweight advantage. The product can increase the overall energy-to-weight ratio of the battery pack and increase the cruising range. Take new energy vehicles as an example. At present, the connection of YTFX products on each new energy passenger car is about 5 kg, and each new energy bus uses about 50-70 kg, which saves about 50% of the weight.

As we all know, subway and high-speed rail car bodies are made of aluminum alloy, and the power distribution system is made of copper. The grounding safety connection between copper and aluminum used to be imported from the United Kingdom. Now YTFX’s copper-aluminum composite materials have been imported. Instead, it reduces the price while also achieving performance improvements.

In the field of electric power fittings, it is estimated that there will be about 10,000 tons of copper-aluminum transition material demand every year, and the market size will exceed 1 billion yuan. The previous power fittings products used friction welding, and there was a risk of fracture under the painful conditions of heating and vibration, which was a high risk to the safety of the entire power grid and the maintenance of the power grid, and the cost was high. YTFX’s newly developed “new copper-aluminum transition terminal” product (commonly known as wire nose) solves the long-term unreliable service problem caused by direct welding of copper and aluminum in the field of power fittings, and effectively promotes the transformation and upgrading of the power fittings industry and the safe and continuous operation of the power system .

Since YTFX products were introduced to the market in 2012, they have quickly gained market recognition. At present, more than 20 leading domestic and foreign companies such as Goldwind, Siemens, ABB, Schneider, etc. have adopted the copper-aluminum composite busbar produced by YTFX company instead of pure copper busbar. Power transmission and distribution equipment has been tested and its performance fully meets the requirements for use.

The company now has an annual production capacity of 8,000 tons of copper-aluminum composite materials.

YTFX Bimetal Composite Material Technology

YTFX Bimetal Composite Material Technology was founded in 2000, is a well known company specialized in manufacturing and developing CCA (Copper clad aluminum) bimetal in China.

It is a preferred supplier of ABB, Siemens, Schneider and other electrical industry giants

The company covers an area about 115,000 square meters with the advanced R & D facilities and equipments and built the first horizontal continuous casting production line for Cu- Al bimetal in the world, YTFX has the annual output capacity of 28,000 Metric tons for CCA Busbar ranging from 20mm-120/150mm in width x 3mm-15mm in thickness; 8,000 Metric tons for CCA wireΦ1.02㎜-Φ6.0㎜

Since its founding ,YTFX has been working as the partner of University of Science and Technology China ,adopted their two national invention patents of Continuous Casting technology for CCA bimetal ,started pioneering work on the state high technology program (863 program) for Cu-Al compounded material. The company has 18 invention patents and is honored as hi-tech enterprise by the government now.

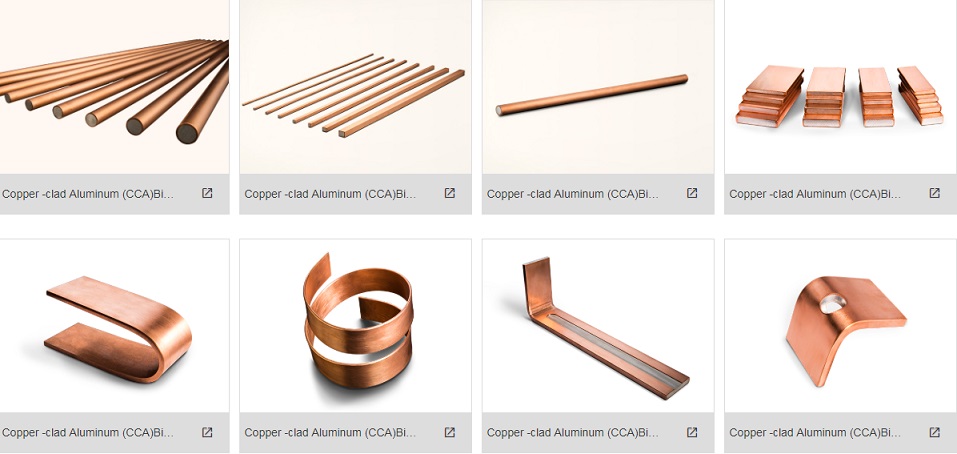

Products

Copper -clad Aluminum (CCA)Bimetal Busbar

Copper-clad Aluminum (CCA)Bimetal Busbar with Nickel plating