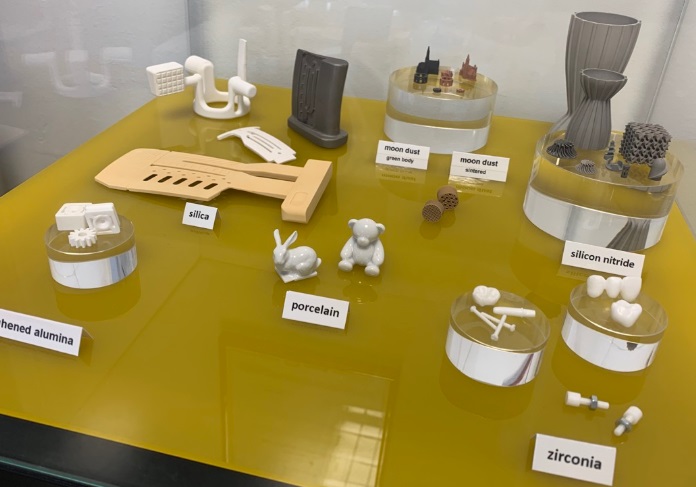

ADLI offers its customers various ceramic powder materials for the additive manufacturing of high-performance and bioresorbable ceramics. Each raw material has been developed to perfectly suit ADLI's technology and to facilitate the production of high-quality parts.

ADLI supports its customers with choosing the right materials.

ALUMINUM OXIDE

The high-purity aluminum oxide (99.99% and 99.8% respectively). Alumina is one of the most important oxide ceramic materials and is characterized by high levels of hardness as well as good corrosion and temperature resistance. Components made from alumina are electrically insulating and puncture-proof and are therefore suitable for a wide range of applications, such as substrates in the electronics industry, thread guides in textile engineering, protection in thermal processes and many others.

ZIRCONIUM OXIDE

The 3 mol% yttria stabilized zirconia, Zirconia is used for applications with extreme demands on the material. High-end metal forming, valves, bearings and cutting tools are some of the applications which benefit from the mechanical properties of zirconia.

The biocompatibility of zirconia facilitates its use in medical applications, such as dental applications and as part of permanent implants.

SILICON NITRIDE

Silicon nitride ceramic powder exhibits superior material properties such as high strength, high toughness, thermal shock resistance and good chemical resistance to corrosion by many acids and alkalis.

It has a wide range of applications including insulators, springs, impellers and more. Furthermore, it can be used for the medical engineering of permanent implants due to its osseointegrative potential and anti-infective properties.

HYDROXYAPATITE AS BONE-REPLACEMENT MATERIAL

The material is based upon hydroxyapatite, a naturally occurring mineral that forms the main component of bones. Due to its similarities to the inorganic components of bone, It possesses excellent biocompatibility and osteoconductivity and has a number of potential applications as a bone substitute. In comparison to tricalcium phosphate, hydroxyapatite takes far more time to be absorbed into the body, therefore giving the body more time to heal. Using the material, we can manufacture patient-specific, bioresorbable implants, which have defined pore structures and geometries. These implants will be reabsorbed by the body and will be replaced by native bone tissue, meaning that the implant does not need to be removed once the healing process is finished.

SILICA-BASED MATERIALS FOR CASTING CORES

This material is mainly based on silica with addition of alumina and zircon. It is used for the production of casting cores for investment casting. Typical applications include single crystal casting of turbine blades. It is developed for the additive manufacturing of precise ceramic cores with fine details and high accuracy. Sintered ceramic cores made from the material have very low thermal dilatation up to 1500 ° C, a high porosity, outstanding surface quality and a very good leachability.

Other 3D printed ceramic materials

Alumina toughened zirconia (ATZ)

Zirconia toughened alumina (ZTA)

Cermets

Cordierite

Magnesia

Porcelain

Glass-ceramics

Transparent ceramics

Bioglass

Piezoceramics

RF dielectric ceramics

Titanium dioxide

…