JPNG Copper Alloy Material Technology Group is a global leading manufacturer of precision beryllium copper alloy wire, beryllium copper alloy foil, copper-nickel-tin high-performance heat-resistant elastic alloy material, high-performance conductive elastic copper-nickel-tin alloy material.

Compliance mark of European RoHS directive

The beryllium copper products (plates, strips, rods, wires) produced by JPNG are fully compliant with the European RoHS directive.

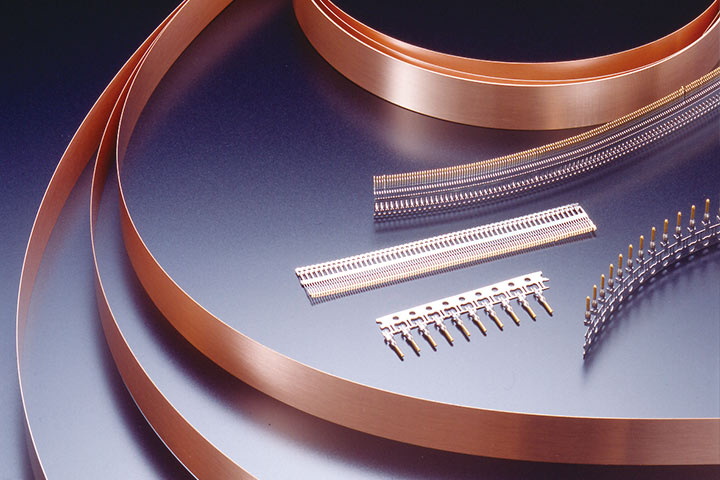

I:Precision Beryllium Copper Products

Beryllium copper is a copper alloy that combines strength, conductivity, workability, fatigue resistance, heat resistance, and corrosion resistance. It is widely used in the field of electronic components such as connectors, switches, and relays. JPNG beryllium copper has a variety of alloys of different specifications to choose from, and can provide strips, plates, bars and wires.

Strength

The aging material has a tensile strength of 1500N/mm2 through aging hardening treatment, so it can be used as a high-strength elastic material that can withstand higher bending stress.

Processability

The "aged material" before the aging hardening treatment can be subjected to complex forming processing. In-plant hardening materials that do not require post-processing heat treatment B and S are materials with excellent balance of strength and formability.

Conductivity

According to different alloys and specifications, the conductivity can reach the range of IACS (International Annealed Copper Standard) of 20 to 70%. Therefore, it can be used as a highly conductive elastic material.

Fatigue resistance

Because of its excellent fatigue resistance (high cycle times), it is widely used in parts requiring long life and high reliability.

Heat resistance

Because the stress relaxation rate is still very small in a high temperature environment, it can be used in a larger temperature range.

Corrosion resistance

Compared with copper alloys such as nickel silver, beryllium copper has better corrosion resistance. Copper alloy material that is hardly affected by the environment and undergoes corrosion changes.

Precision beryllium copper beryllium copper extension material

Beryllium copper extension materials are mainly supplied in the shape of sheets, strips, and bars. Because beryllium copper has high strength, high electrical conductivity, fatigue resistance, high thermal conductivity, processability, and corrosion resistance, it is used as an elastic material. widely used.

In order to be suitable for various purposes, we have prepared various types of beryllium copper alloy strips and foils with different hardnesses. The thinnest material can be provided with a thickness of 0.045mm.

The minimum diameter of beryllium copper wire is 0.05mm

Beryllium copper bar, thick plate

In addition to shapes such as rods and plates, it can also be processed according to the shapes required by customers.

II:Precision copper nickel tin products

A copper-nickel-tin alloy made by adding nickel and tin to copper, metastable decomposition through age hardening, a high-performance copper alloy with high strength, heat resistance, and abrasion resistance that can match beryllium copper.

Copper-nickel-tin extension materials are supplied in the form of plates and strips as the main products. They have high strength, fatigue resistance, high temperature characteristics, workability, and corrosion resistance, and are used as elastic materials in many applications.

Features

High-performance conductive elastic material

Copper-nickel-tin is an age-hardening copper alloy with nickel and tin added and metastable decomposition. A high-performance conductive elastic material with high strength and heat resistance comparable to that of beryllium copper, and the same conductivity as phosphor bronze. Due to the comprehensive performance of strength and conductivity, it can be used for various applications such as connectors and switches.

High-performance heat-resistant elastic material

Copper-nickel-tin is an age-hardening copper alloy with nickel and tin added and metastable decomposition. A heat-resistant elastic material with high strength comparable to that of beryllium copper, and the highest level of corrosion resistance and heat resistance among existing copper alloys. Suitable for high-performance elastic materials used in harsh environments such as automobiles and industrial machinery.