USTT Composites Technology Company has rapidly become one of the world leaders of advanced thermal management materials and solutions for the electronics industry. Today USTT produces thermal management and structural products for systems ranging from telecom satellites and military hardware, to high performance microprocessor assemblies and IGBT power conversion modules for traction and next generation hybrid and fuel cell vehicles.

USTT provides system and product engineers the ability to solve thermal and structural problems with high performance material-based solutions, combined with maximum design flexibility. In the past, such problems were typically solved with metal or ceramic solutions, often compromising product performance and/or design. However, USTT approaches the problem differently by combining metals and ceramics to create materials having properties that can meet multiple performance and design specifications, while improving overall system reliability.

The results are products having the unique combination of high thermal conductivity – over 250 W/mK, tailorable thermal expansion – 4.5 to 16 ppm/K, low mass – 3 g/cm3, high stiffness 250 to 330 Gpa, and no thermal cycle aging effects (debonding of the filler and matrix over long-term thermal cycling)-ie no compromise solutions!

Production Facilities

By incorporating the processes with state-of-the-art manufacturing techniques, USTT operates one of the world's most advanced metal matrix production facilities, producing components with the highest quality at the lowest possible cost. USTT's production processes are based upon an integrated semi- continuous manufacturing system, coupled with flexible manufacturing concepts:

Design:

Working from customer requirements and designs USTT`s engineers, using CAD/CAM workstations, can quickly develop and produce quick-turn prototypes and eventually production components

Preform Fabrication:

For preform based applications tape casting, low pressure injection molding, high-volume dry pressing and green-machining operations provide the lowest cost preform options currently available.

True Flexible Manufacturing:

Part flow through the infiltration based production line is continuous regardless of shape, size or complexity, thereby minimizing costs and down times typically required for tooling changes. In addition, unlike competing MMC technologies, USTT's pressureless process does not require a tool to contain the preform during infiltration, which leads to further cost savings.

Casting Operations:

For casting requirements, USTT supplies aluminum silicon carbide concentrate to approved casting companies to provide die, investment and permanent mold cast components meeting USTT`s high-quality physical and thermal requirements.

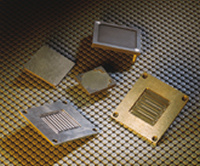

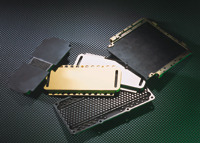

Surface Finishing:

Using proprietary plating processes, USTT offers nickel, gold, silver, copper, tin, and cadmium surface finishing. These processes yield surfaces with excellent surface coverage, solderability, solder joint reliability, and corrosion protection. USTT's nickel and nickel-gold plated aluminum silicon Carbide components have been successfully tested blister-free up to 450°C in air, suitable for even the most demanding solder bonding requirements. In addition, anodizing, chemical conversion coatings, and epoxy primer coatings are also available.

Custom Part Fabrication:

Although the production facilities are optimized for high-volume part fabrication, USTT maintains a complete machine shop with state-of-the-art CNC machining centers that include: milling, grinding, water-jet cutting and electro-discharge machining operations, for quick turn prototype and low-to-moderate volume component production.

Products and Solutions

Engineered for solving thermal management and structural problems in severe environments, USTT's Al/SiC components meet these challenges through cutting-edge composite technologies that combine the best properties of both metals and ceramics. This approach allows USTT to tailor the properties of the final product to meet multiple performance requirements, such as thermal expansion, weight, stiffness, and thermal conductivity without the compromises often associated with traditional material solutions.

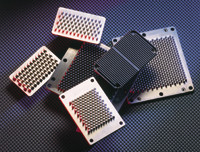

Power Module Base Plates and Heat Sinks:

The reliability of high performance IGBT and MOSFET power modules can be significantly improved by replacing standard copper base plates with base plates that closely match the thermal expansion of the ceramic substrates carrying the power die.

Microprocessor Lids and Heat Spreaders:

In microprocessor packaging applications considerable cost savings and substantial package weight reduction can be realized through the replacement of copper/tungsten and copper/molybdenum. In addition, The Lids can be provided with CTE values ranging from 6.8ppm/C to 16 ppm/C.

Printed Wiring Board Cores:

PWB cores improve surface mount assembly reliability by minimizing thermal cycling and vibration fatique, as well as providing excellent thermal performance, while saving up to 70% of the weight of conventional metal cores.

Carriers and Hybrid Package Bases:

The carriers and package bases have demonstrated weight savings ranging from 33% to over 80%, while matching or exceeding the thermal performance of Cu/W and Fe/Ni alloy based components.

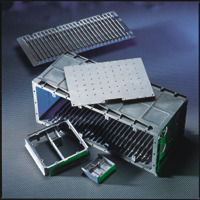

Electronic Chassis and Enclosures:

The chassis and enclosures have achieved weight savings of more than 45%, with improved dimensional stability over those manufactured from machined aluminum.

components are designed for systems requiring high-thermal dissipation through active air or liquid cooling.

The product line adds two additional levels of capability:

components, designed as rugged one-piece Al/SiC heat exchangers with internal pin or fin cooling features, are offered for severe environment and mission critical applications. The printed wiring board cores, power module heat sinks/base plates and custom design heat sinks are found in numerous aerospace and defense, high-end commercial applications.

components combine the simplicity of the line with active cooling pin or fin cooling features and are offered for applications where maximum performance, design flexibility, and economy are required. In addition, unlike competing Al/SiC designs from other suppliers, The components have all Al /SiC pins, not molded on aluminum pins. The power module base plates and custom heat sinks are found in automotive, traction (electric powered train) and stationary power system applications.