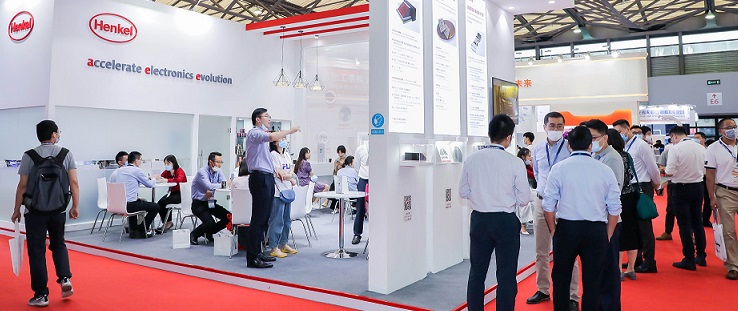

On June 28, 2020, SEMICON China, the annual event of the semiconductor and electronics industry, was grandly held in Shanghai. Henkel, a leader in the global adhesive market, once again appeared at this exhibition. During the exhibition, the adhesive technology and electronic materials business showcased innovative products and solutions applied in advanced packaging, memory and camera modules.

Advanced packaging

At present, the global semiconductor industry is at a turning point. The explosive growth of data has promoted the demand for high-performance computing in data-centric server, client, mobile and edge computing architectures, and the need for 5G deployment, small and medium-sized handheld device packaging and The continuous demand for integration, these trends have promoted the gradual maturity of advanced packaging. The current rapid development of semiconductor and packaging technology, the increasing demand for high performance, small size, high reliability, and ultra-low power consumption of chips and electronic products has prompted continuous breakthroughs in advanced packaging technology. At the same time, due to the vigorous development of emerging industries such as artificial intelligence, autonomous driving, 5G networks and the Internet of Things, the market has increasingly strong demand for advanced packaging.

In response to these needs, Henkel has introduced a series of solutions, including liquid compression molding materials for fan-in/fan-out wafer-level packaging and back protection film LOCTITE ABLESTIK BSP 100, designed for challenging, low gap and fine pitch Capillary underfill LOCTITE ECCOBOND UF 8000AA designed for flip chip devices, and LOCTITE ABLESTIK ABP 8068TB semi-sintered die attach adhesive for power ICs and discrete devices to meet higher heat dissipation requirements.

The liquid compression molding material used for fan-in/fan-out wafer-level packaging has very low warpage after molding, and it can be cured quickly and molded at low temperature to achieve high output and is suitable for various wafer-level packaging Form; the back protective film of LOCTITE ABLESTIK BSP 100 has the characteristics of low warpage, excellent reliability and workability, as well as strong reworkability; LOCTITE ECCOBOND UF 8000AA, which is specially designed for flip-chip devices, has a variety of substrates Excellent wetting characteristics and good reliability, with the advantages of long online operation time, good fluidity, high productivity, etc.; LOCTITE ABLESTIK ABP 8068TB semi-sintered die attach adhesive for power ICs and discrete devices, in silver, copper, PPF base material has good sinterability, can provide the same good workability as traditional silver paste, and has excellent electrical stability and thermal conductivity, and its lead-free formula is more environmentally friendly.

During the exhibition, Henkel's Adhesive Technology Electronic Materials business showcased innovative products and solutions applied in advanced packaging, memory, and camera modules.

Memory

With the vigorous development of the electronic industry, electronic technology continues to evolve, and the design of electronic products is also moving towards the trend of light, thin, short and small. Stacked chips have become a leading technology for advanced integrated packaging, which can enhance the functions of memory chips without increasing the package volume. In order to meet the ever-evolving chip stacking requirements, thinner wafers are essential. Therefore, effective handling and processing of thinner wafers, such as 25-50μm in thickness, is essential for semiconductor components.

Henkel's newly launched LOCTITE ABLESTIK ATB 100MD8 non-conductive die attach film is designed for stacking and packaging chips, which can help make memory devices. This solution can achieve a thin package, and has excellent workability and excellent reliability. In terms of workability, it has good Thermal Budget performance, no glue thread, no dual-chip pick-up phenomenon, and stable wafer cutting and chip pick-up performance, especially suitable for thin and large chip applications.

For the high-bandwidth memory (HBM) of the 3D three-dimensional stacked package, Henkel launched the pre-filled underfill non-conductive film LOCTITE ABLESTIK NCF 200 series, which is a transparent two-in-one film with very small overflow control. The conductive bumps can be protected during the manufacturing process. Supports compact layout, low-height copper pillars, and is designed for lead-free, low K, small pitch, large-size thin flip chips.

Camera module

In the field of consumer electronics, although the global smartphone growth is becoming saturated, smartphones with more than two multi-cameras have accounted for half of the entire smartphone market as smartphones are heading towards higher image performance and recognition and sensing functions. In the latest mobile phone releases of major brands, smartphones ranging from three cameras to six cameras have also emerged in an endless stream, thus forming a huge market demand for the bonding and assembly of mobile phone cameras.

However, camera module manufacturers need more reliable structural bonding, higher yield and more optimized production processes to meet the integration requirements of multiple fixed-focus or zoom camera modules with precise structures, and higher imaging Quality requirements.

To this end, Henkel has launched a comprehensive solution for camera module adhesion protection materials from image sensor chip bonding and conduction, lens alignment, module assembly protection to soft board reinforcement. LOCTITE ABLESTIK NCA 2286AD lens holder adhesive can be used for active lens alignment. Its excellent blackness and low light transmittance can meet the needs of special narrow bezels and can be cured quickly. In addition, LOCTITE ABLESTIK NCA 9493 room temperature curing adhesive, fast surface drying in 20 minutes, 24 hours curing at room temperature, and excellent dispensing ability.

With innovative ideas, professional technology and global resources, as well as strong support for localized production and R&D in China, Henkel Adhesive Technology helps customers solve challenging problems. As a global leader in innovation and adhesive technology, we are committed to bringing new solutions to the market and actively creating value for customers in different industries.