Scientists in Japan are committed to extending the limit of superelastic materials and have made major breakthroughs. They showed a new iron-based alloy that can withstand extremely high and extremely low temperatures. With this ability to deform and return to its original shape under various conditions, the team hopes that its new superelastic metal will find use in more earthquake-resistant buildings, and may even find use in outer space.

Super elastic alloy (SEA) is a kind of material with super elasticity, which enables it to deform and return to its original shape. Their unique characteristics have allowed these durable materials to be used in a variety of fields from glasses and aprons to medical and dental applications, but they also have their limitations in their current form.

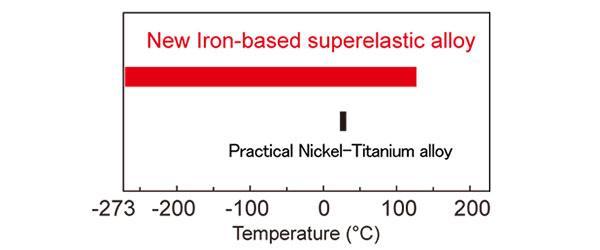

The mechanical force that these materials can withstand is affected by the ambient temperature, and the super-elastic alloys currently used can work in the temperature range of minus 20 °C to 80 °C. These alloys are made of materials such as titanium and nickel and are also expensive, which means they are mostly used in the form of thin wires and pipes.

A team of engineers from Tohoku University in Japan proposed a new formulation of superelastic alloys, which can greatly broaden its potential applications. This new material is made of iron, aluminum, nickel and chromium. By carefully controlling the concentration of chromium, the team was able to produce a super-elastic alloy that is basically unaffected by ambient temperature. Its performance can still be maintained in the environment.

The team believes that one of the more exciting potential uses of its new technology is space exploration. In space exploration, materials used to make aircraft need to be able to withstand deformation in the most extreme environments, such as on the moon or Mars, where day and night temperatures may fluctuate between minus 170 °C and 120 °C. However, it can also find uses closer to home.

"However, the use of the new SEA does not stop there." said Professor Toshihiro Omori, who led the research team. "It may be used for tensile braces in buildings or column elements in bridges-to provide greater seismic resistance."