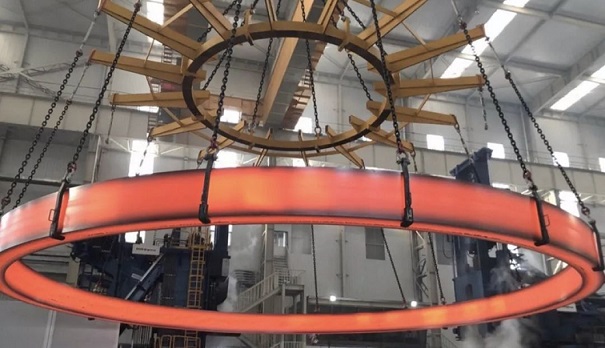

The Metal Research Institute of SDYL Heavy Industry Technology Group announced on March 12 that the world’s largest non-welded integral stainless steel ring forging was successfully rolled on the same day using the metal construction technology developed by the institute.

The ring has a diameter of 15.6 meters and a weight of 150 tons. For the first time, it has realized the hierarchical construction of a hundred-ton metal billet. It is also the world’s largest diameter and heaviest integral forged stainless steel ring.

SDYL used SXTG’s high-purity stainless steel continuous casting slab to successfully develop an annular forging with a diameter of 15.6 meters, which is characterized by no welds, high homogeneity and good structure uniformity. The giant ring will be used in China’s fourth-generation nuclear power unit, and its successful development will effectively guarantee the implementation of major equipment in China’s nuclear industry.

As the core component of China’s fourth-generation nuclear power plant, the support ring is not only the boundary and safety barrier of the pressure vessel, but also the structurally bearing 7,000 tons of weight, which is the “backbone” of the entire reactor vessel. In the past, such giant forgings were manufactured by foreign companies using multi-segment billet group welding. Not only did the processing cycle be long and the cost was high, but the material structure at the weld position was weak, which created potential safety hazards for nuclear power plant operation.

After more than ten years of hard work, SDYL researchers have developed original metal construction and forming technology and revealed the healing mechanism and tissue evolution mechanism of the construction interface, breaking through the limitations of the “big forging” thinking of large forgings and developing surface activation , Vacuum packaging, multi-directional forging, hierarchical construction, integral rolling ring and other series of key technologies, completely eliminate the interface between the multilayer metal, so that the support ring forgings are constructed in the same position as the base metal in terms of composition, structure, and performance. The new processing and manufacturing of “making small and large” greatly improves quality while reducing manufacturing costs.

This technology has been evaluated by many Chinese academicians and experts as a transformative innovation in the field of large component manufacturing. It has been applied in hydropower, wind power, nuclear power and other fields. It will promote the rapid development of China’s high-end equipment and ensure the independent and controllable core materials of major equipment It played an important role.

Typical applications of large seamless forgings

Connect all kinds of segmented barrel equipment

Foundation pile flange made for Siemens 7MW offshore wind turbine[2017]

Transmission Parts

A 10-meter slewing ring manufactured for the world-renowned bearing manufacturer LIEBHERR

Shield machine

Pressure vessel tube section

…