AHYL Precision Machinery Group is a large-scale enterprise group, mainly engaged in the research and development, production and sales of high-temperature alloy precision parts for special equipments. The products are used in aerospace, oil and gas, clean power generation, engineering and mining machinery and other high-end equipment fields.

The group's companies are located in China, Europe and North America, and the main production base is located in Anhui Province. At present, the total assets are nearly 3 billion yuan and more than 3,000 employees. It is a leading exporter of high-temperature alloy precision castings in China, ranking 62th in the machinery industry, 7th in the foundry industry, and 3rd in the cast steel parts industry.

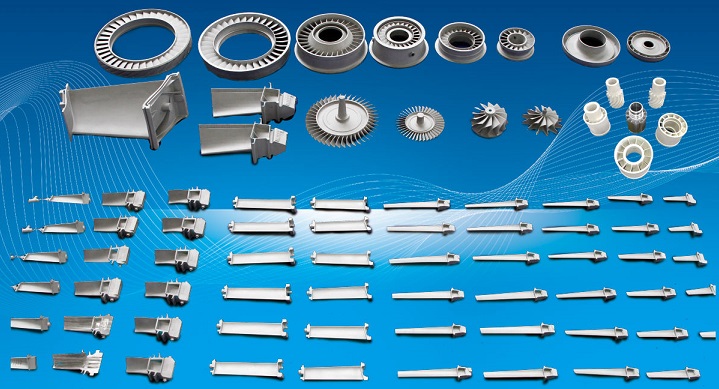

Products

Aero Engine and Gas Turbine Superalloy Precision Parts

The core components of high-end equipment are used in the fields of aviation, energy, oil and gas and resources, and meet international and industry advanced standards. Nuclear first-level product manufacturing qualification, nuclear power plant nuclear island core components industry leading, valve parts exports for ten consecutive years to maintain the industry's first. Undertake major projects in many countries and provinces to achieve the first domestic production. Focusing on high-temperature alloy components of aero-engines and gas turbines, the industrial upgrading and development are promoted to meet the needs of major national equipment and international industry giants.

Aero Engine Titanium Aluminum Blade

Titanium-aluminum blades are a leading and revolutionary technology for high-temperature, high-strength, lightweight materials for aero-engines, and they are also key strategic materials that China urgently needs to develop. In 2007, Luoluo Company commissioned the Institute of Metals of the Chinese Academy of Sciences to develop titanium-aluminum blades and master alloys, which have passed certification. Yingliu won the bidding of Luo Luo China's supplier "two out of ten" and was identified as Luo Luo's main supplier. Yingliu and Metals established a joint venture company to realize the industrialization of titanium-aluminum blades, mass-produce titanium-aluminum blades for Rolls-Royce Trent engines, and participate in the development of its most advanced superfan engines.

Aeroengine and gas turbine superalloy components

Established equiaxed crystal blade production lines, directional and single crystal blade production lines, casings and aviation structural parts production lines. The project has a land area of 130 mu, a building area of 44941 square meters, and a total investment of 1.2 billion yuan, of which 650 million yuan is invested in fixed assets. It is planned to be completed and put into trial production in the first quarter of 2018.

Introduce-More than 240 sets of equipment in seven countries. The process layout and equipment selection are benchmarked by world-class companies such as PCC and Howmet, and have reached the international advanced and domestic first-class level as a whole. After the project is completed and put into production, it will have an annual output of 100,000 high-temperature alloy equiaxed crystals and directional single crystal blades, 500 cases and structural components, and meet the urgent needs of China's advanced aero engines and heavy gas turbines. Gas turbine market.

Superalloy master alloy

AHYL's customers are in more than 80 internationally renowned companies in 30 countries, mainly in Europe and North America, of which 11 Fortune 500 companies have established long-term strategic partnerships with Yingliu. Formed an excellent customer group represented by industries such as General Electric, Siemens, Areva, Alstom, Caterpillar, Schlumberger, Emerson, Leibos, Tyco, etc., including Crane, Emerson-Fisher , Tyco, Siemens and many other customers. Yingliu has obtained more than 30 international authoritative quality assurance system certifications. It is the first in China to obtain a civil nuclear safety machinery and equipment manufacturing license issued by the National Nuclear Safety Administration. In accordance with domestic and international advanced technology, It is equipped with equipment for research and development, manufacturing and quality assurance. It has a complete industrial chain of casting, machining, and modular manufacturing, which can quickly meet customers' various complex needs.