JEC is the world's most prestigious professional exhibition of composite materials in Paris, France. Its large scale, high degree of professionalism, and wide coverage attracts chemical, material, energy, automotive, aerospace, construction engineering, and consumer goods. Every year, outstanding companies from various major industries come to participate in the event. From 3.6 to 8 this year, more than 1,300 exhibitors and more than 40,000 professional visitors came to the Villepin Exhibition Center in the northern suburbs of Paris, France to explore the possibilities of composite materials.

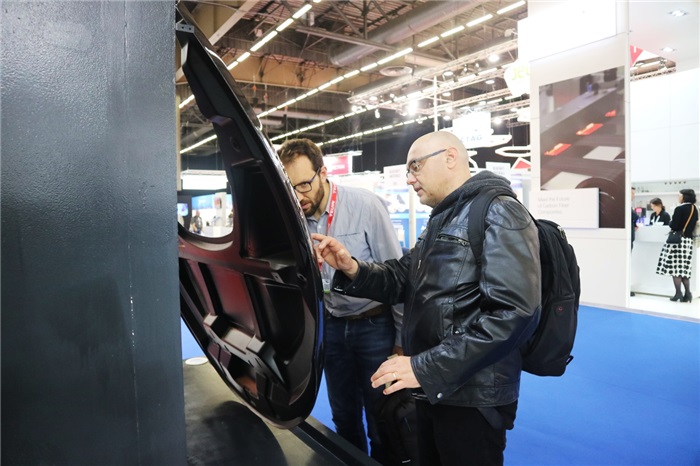

JSHR Advanced Composite Materials Engineering Technology Company, as a rising force in China's composite materials industry, has not only brought in mass-produced auto parts exhibits that represent leading technology and quality, but also stood out among many exhibitors with a refreshing image and gave many professionals The visitors were impressed. At the same time, its professional international team also held close and fruitful negotiations with the industry's upstream and downstream during the exhibition, and comprehensively demonstrated the precise deployment on the industrial chain as Asia's leading composite solution provider focusing on processing and molding. And positive results.

In summary, the exhibits presented by JSHR are: sophisticated selection, difficult development, excellent craftsmanship, and good quality. It can be said that the main domestic "star" new energy models have been collected, representing the most advanced carbon fiber in China and the world The leading practice cases of large-area body applications have a valuable reference for the composite materials and automotive industries.

Full carbon fiber hood

Full carbon fiber trunk lid, side wall assembly, door assembly

One of the sources of the exhibits is the promising K50 pure electric carbon fiber sports car. The application of carbon fiber parts in this model covers all outer coverings such as car roofs, doors, hoods, fenders, and bumper trims. It has created a large body in China. The first in a range of composite applications. JSHR, as a full-scale composite technology partner for this model and a major composite component supplier, has jointly developed and contracted 28 of the 31 carbon fiber components of the body. The cooperation between the two parties has caused huge changes in the field of electric new energy vehicles. Sensational effect. The overall weight of the hood on display at this time was only 10.8kg, while the weight of a common steel stamped hood was about 20kg, achieving a 50% weight reduction. The surface quality of the hood is good, and the tensile strength of the inner and outer plate connection is significantly reduced in terms of cost through optimization of processes and production procedures, which is suitable for large-scale continuous production.

Another highlight is JSHR's 11-part hood manufactured by Chongqing Fast Star New Energy Automobile Co., Ltd. (hereinafter referred to as “Chongqing Fast Star”), which includes the door, rear tail, and bracket, which represents the most technical height. As another popular car model with purely independent intellectual property rights in China, "Fast Star" pure carbon fiber electric sports car has achieved 50% weight reduction compared to the body-in-white and is actively preparing for mass production. Officially launched in 2019.

JSHR was born as an Asian component molding company. It can be said that it has broken the technical monopoly of automotive carbon fiber applications in European and American companies. It has given practical reference and great confidence to the Asian automotive industry, especially new energy vehicles for the application of composite materials In particular, the company's industrial-grade rapid mass production capabilities and carefully polished high-level R & D standards that integrate comprehensive materials and automotive comprehensive knowledge have attracted major automotive OEMs in Europe, America, Japan, and South Korea to come to consult and negotiate.