GSJC Precision Packaging Materials Technology Corporation is committed to the research and production of high-precision “irregular copper strips”.

The reason for the irregular copper strip is that its surface is not flat, but has a raised T-shaped platform, which is an important semiconductor packaging material.

The use of special-shaped precision copper strips for lead frames is a crucial material in the electronic information industry, such as integrated circuits and discrete semiconductor devices. As a carrier of integrated circuit chips, the lead frame is a key structural component that uses bonding wires to connect the internal circuit leads of the chip to the external leads through the internal leads, forming an electrical circuit.

In semiconductors, the lead frame mainly plays a role in stabilizing the chip, conducting signals, and transmitting heat. It needs to have high performance such as heat resistance, corrosion resistance, conductivity, and thermal conductivity. With the development of integrated circuits towards miniaturization, thinness, lightweighting, and multifunctionality, high-strength and high conductivity lead frame materials have gradually become the mainstream in the market.

|

|

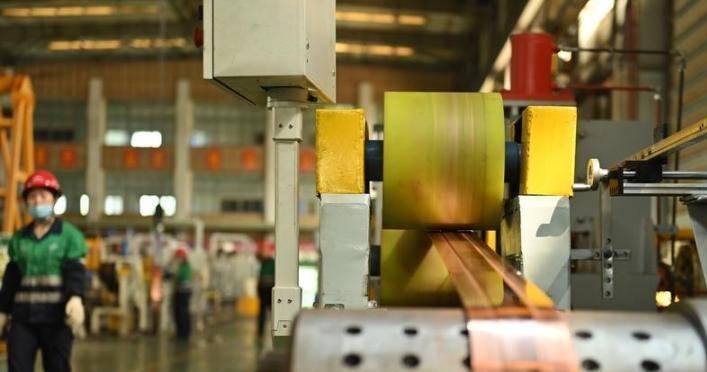

At present, the “special-shaped precision copper strip” developed by GSJC is mainly based on extrusion rolling technology. After 3 years of research and production, it has mature production technology and currently produces more than 40 types of “special-shaped precision copper strips”.

On the basis of the original production line for rolling “special-shaped precision copper strips”, GSJC has successfully developed an integrated core production equipment for forging and rolling, and pioneered the dual process connection technology for forging and rolling in China. The special-shaped precision copper strip, which originally had to go through 12 processes to be produced, can now be formed in one go on the forging and forging integrated production line.

At present, the integrated forging production line developed by GSJC has a forging frequency of 1000 times/minute and a production speed of 7 meters/minute. The product size accuracy (error) has reached 0.015 millimeters, and the relevant technical indicators have reached the advanced level in China.

GSJC is the only production enterprise in China that has dual processes of rolling and forging. The comprehensive performance of the “special-shaped precision copper strip” produced by GSJC is better than that of the rolled copper strip used in the market, and it is leading in technology and process in China.

The sales volume of high-end forged “special-shaped precision copper strips” produced by the department has reached 1200 tons per year, accounting for 50% of the market share in China.