- Export Business

- high performance & advanced materials and its product

- ultra precision parts & components

- innovative technology products

Private Enterprise Procurement Management Consulting Project Case Review

A case study of procurement management consulting project for a private manufacturing company in Yangzhou, Jiangsu

Client Enterprise: Jiangsu Machinery Industry Co., Ltd.

Main business: Processing and manufacturing of automotive transmission parts

Annual output value: 380 million RMB [2018]

Main procurement materials: automotive transmission parts, forged parts, cast aluminum parts, machining tools, machine tool spare parts, cutting fluid …

The company produces auto parts. Although the company has passed IATF 16949 certification, it has not been managed and implemented in accordance with the system documents in actual production operations. The simple and rough purchase price comparison is simply comparing prices and payment terms. The procurement negotiation strategy is Win-Lose strategy. Most suppliers lack effective quality control methods. The quality of delivered products is endless, leading to production line shutdowns, customer returns and complaints. Due to deliberate delays in payment, supplier relationships have gradually deteriorated. The end result is often To change suppliers, due to the poor reputation of the company, almost all purchases have to be paid in advance, and it is almost impossible to run.

In the end, the general manager of the company was distressed and found Hay Think, hoping that Hay Think can provide them with customized procurement management solutions to solve the crisis they face …

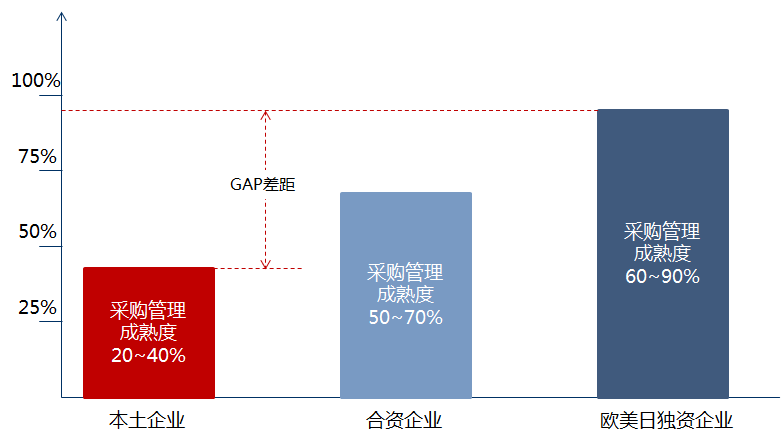

Hay Think conducted a professional evaluation of the procurement team of client companies based on the ProMA Procurement Management Maturity Professional Evaluation System. Their procurement management maturity is only 18%:

The following are the evaluation results and corresponding solutions provided:

SITUATION

No awareness of procurement strategy requirements management;

No procurement strategy development capabilities;

The planning and setting of the procurement organization is unreasonable and cannot meet the strategic development needs of the enterprise;

The procurement organization KPIs are not set properly;

The purchasing team lacks the necessary competencies for the position;

Lack of task management in procurement organizations;

Management of procurement documents is chaotic;

There is no corresponding procurement management process and standard template;

No awareness of supply market management;

No project management concepts;

The procurement management process for new projects is unclear;

Many project purchases have not been participated in advance;

The procurement technical specification TS was not reviewed and clarified;

There is no uniform structured inquiry form for purchase inquiry, and the supplier's quotation is not comparable;

Supplier selection and evaluation system is unscientific;

Supplier risk is not effectively monitored;

Loose supplier relationship management;

Missing supplier performance assessments;

Missing vendor development;

Lack of purchasing / supplier quality management tools;

Production interruptions and customer complaints from time to time due to supplier quality issues;

Low customer satisfaction;

…

Consulting tasks TASK

Establish a complete procurement management system based on lean concepts and strategic procurement;

Purchasing organization planning and team building to meet the needs of corporate strategic development;

Identifying procurement risks

Discover purchasing opportunities

Improve procurement quality

Reduce procurement costs

…

ACTION / SOLUTION

The Hay Think management consulting team communicated the evaluation results and solutions with the company's senior management and reached the following action plans:

Introduced the concept of lean management;

Introduced TCO purchasing management concept;

Establish a procurement demand management mechanism;

Trained the procurement strategy development process;

According to the corporate development strategy, reorganized the procurement organization structure and defined the procurement function;

Provide procurement team competency model and relevant competency training;

Rewritten procurement process and standard template files;

Introduce strategic management concepts for the supply market

The principle of purchase price comparison sets gradient price comparison according to the order amount;

The procurement team strengthened the clarification of TS in PR;

The inquiry form uses a unified structure inquiry form;

For emergency procurement, set up a green channel for emergency procurement [The basic premise is to have a PR number and an internal email, which needs to be confirmed by the buyer`s leader]

Introduce project procurement management tools: import project management tools, product concept competition, D_FMEA, P_FMEA, APQP, MSA, SPC, PPAP and other management concepts and tools for project procurement;

Perform purchasing cost analysis, identify purchasing risks and identify purchasing opportunities:

Classify the top 100 materials according to their importance according to their importance, and classify them into A, B, C and Kraljic Model or Kraljic Matrix. Different types of materials use different procurement strategies;

Add quality assurance agreement QAA, logistics manual agreement LMA, etc. to the purchase contract

Supplier Management Introduced the supplier pyramid management model of Bosch in Germany, different strategic positioning and implementation of different supplier strategies for different suppliers

Established a supplier relationship management system: a new supplier evaluation system; a supplier site inspection and evaluation system; a supplier selection evaluation matrix; a supplier performance evaluation system; a supplier potential development evaluation system;

Supplier development strategy changed from Win-Lose to Win-Win strategy;

Machine tool spare parts introduce the concept of TPM;

…

Result RESULT

30% reduction in procurement costs [average savings of 60 million / year];

60% reduction in procurement quality costs;

Product on-time delivery rate reached 99%;

80% reduction in inventory;

Equipment OEE increased by more than 40%;

Procurement compliance rate increased to 98%;

Customer satisfaction increased by 60%;

Significant improvement in supplier relationships;

The maturity of the purchasing team has increased by more than 50%

…

Hay Think professional procurement management system is creating value for many companies …