On October 12, 2023, at the International New Energy Technology and Equipment Expo, China’s leading silicon carbide fiber technology provider, HNZR Advanced Materials Technology Corporation, released a new product:

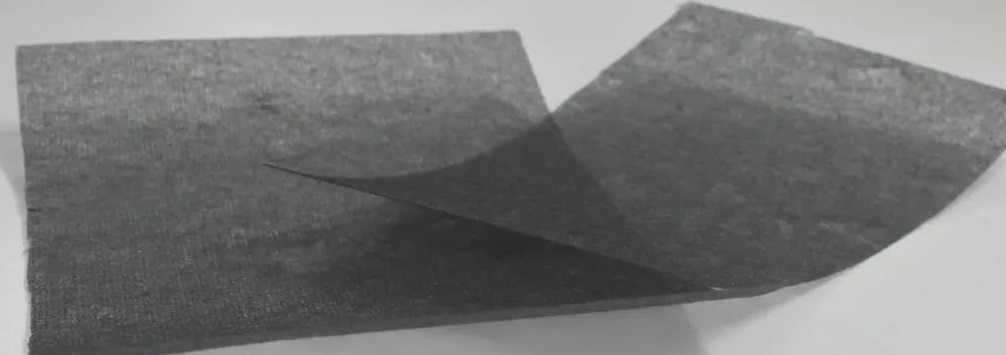

High performance silicon carbide fiber insulation felt, which can withstand high temperatures of 1300 ℃.

Previously, carbon fiber felt was used in the industry, and silicon carbide fiber felt is still the first time I have seen it! “On site, HNZR’s new silicon carbide fiber felt product was exhibited, attracting the attention of experts from well-known industry units such as Longji Green Energy, China Electronics Technology, and Donghua University.

In fields such as aviation, aerospace, and new energy, due to the special needs of industry applications, there is a clear demand for products with high temperature resistance, wear resistance, and portability. Carbon fiber products with this performance have always been popular and widely used in these fields. According to statistics, carbon fiber can withstand high temperatures up to 400 ℃ in aerobic environments.

The silicon carbide fiber insulation felt product released by HNZR this time is an upgrade and replacement of carbon fiber products in the industry. It is formed using a unique wet non-woven process and is resistant to high temperature, oxidation, acid and alkali, corrosion, and has broad application scenarios. After testing, the silicon carbide fiber felt can withstand high temperatures of 1300 ℃.

We are honored and proud to have provided this new product for the first time in the industry,Dr. Huang confessed. As a leading global supplier of high-performance silicon carbide fibers, HNZR has a fully automated and controllable production capacity for silicon carbide fibers, providing the widest range and largest production capacity of doped silicon carbide fibers.

About HNZR

HNZR is committed to the development and production of high-performance silicon carbide fibers.

The company has a fully process independent and controllable production capacity of silicon carbide fibers, and is a leading global enterprise in the research and industrialization of doped silicon carbide fibers. It can provide the most comprehensive and largest production capacity of doped series silicon carbide fibers. The company is committed to becoming an internationally competitive supplier of high-performance silicon carbide fibers.

The company has a strong talent team and technical strength

Professor Huang, the founder and chief scientist, is a doctoral supervisor at Central South University and the director of the Institute of Silicon Carbide Fiber Composite Materials at Central South University.

The total number of employees in the company is nearly 300, including 63 doctoral degree holders and 28 scientific research personnel with overseas study and visiting experience.

Relying on two provincial-level scientific research platforms, namely the provincial engineering laboratory for silicon carbide fibers and their composite materials and the provincial research center for doped silicon carbide fiber engineering technology, the company has achieved a breakthrough in the industrialization of silicon carbide fibers, established a large-scale production base, and formed multiple series of silicon carbide fiber maintenance. Currently, it has nearly 20 related patents and independent intellectual property rights.

Product

Temperature resistant series silicon carbide fibers

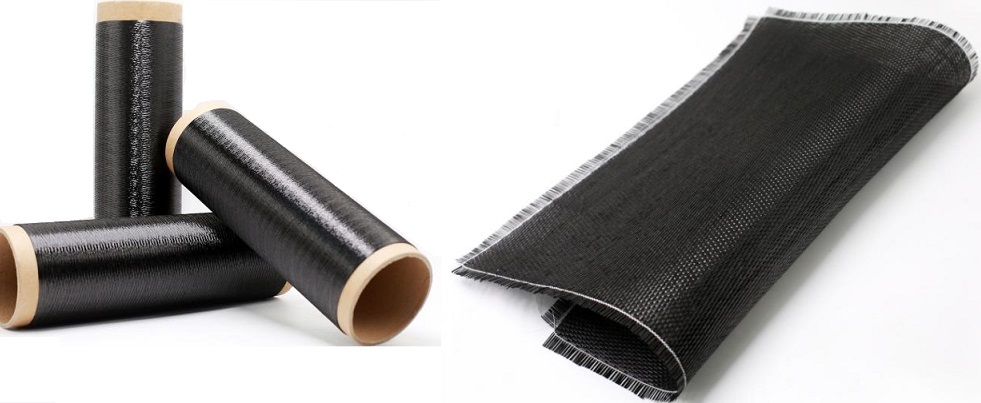

Silicon carbide fiber

Doped silicon carbide fiber

Doped silicon carbide fibers have excellent properties such as low density, high strength, high modulus, creep resistance, wear resistance, high crystallinity, near stoichiometric ratio, corrosion resistance, and high temperature oxidation resistance. In high-temperature environments above 1500 ℃, their mechanical properties remain basically unchanged, and the temperature of use in aerobic environments is much higher than that of carbon fibers.

Silicon carbide fibers are mainly used in the aviation and aerospace fields, such as high-temperature resistant parts such as blades, adjustment plates, combustion chambers and insulation screens of aircraft engines, and rudder wings of missiles.

High performance series silicon carbide fibers

Silicon carbide fiber cloth

Polycarbosilane (PCS)

Silicon carbide fiber felt

Special wave transmitting silicon carbide fiber

…

The high-performance silicon carbide fiber and silicon carbide fiber insulation blanket developed by the company have been successfully applied in the fields of hot end new materials such as aerospace and nuclear power.