On April 1, 2020, SLM Solutions announced that it has formally established a strategic cooperation with the well-known Chinese medical device manufacturer ZJKH Medical Device Group. ZJKH selected SLM Solutions equipment for 3D printed medical device product development. SLM Solutions will assist ZJKH in metal 3D R & D and production of printing implants, providing technical and application support to help them achieve product certification and mass production as soon as possible.

ZJKH Medical Device Group is a leading enterprise in technological innovation of China's medical implant industry. Founded in 1994, it focuses on the research, development, manufacture and sale of orthopedic implants, orthopedic surgical instruments and post-operative intelligent rehabilitation equipment (CPM): covering products Such as femoral nail, titanium plates and screws, pedicle screw with rods, PEEK cage, balloon kyphoplasty for spine fracture and other instrument sets, rooted in the orthopedic medical device subdivision field for twenty-five years, with excellent product quality among the Chinese orthopedics It is a leading manufacturer and has become a leader in OEM of orthopedic medical instruments and surgical tools in the Asia-Pacific region.

"We are extremely proud of winning the trust of ZJKH. SLM Solutions is the pioneer and leader of laser selection melting (SLM) technology. The medical field is also one of the important application areas of SLM Solutions. Our global experience accumulation and research and development Innovation will help us make great efforts in the Chinese medical field, and cooperation with innovative companies like ZJKH, I believe that it will effectively promote the breadth and depth of the two-dimensional development of 3D printing technology in the medical industry. "General Manager of SLM Solutions Asia Pacific Ma Jianli said.

The advantages of SLM Solutions in the medical field:

The fully enclosed powder processing system of the equipment fully complies with the safety and quality requirements of the medical industry;

Leading and mature multi-laser technology, two-way powder spreading, and optimized and upgraded wind field technology have outstanding performance in printing efficiency and quality control;

In the process development field, more than 200 parameters are all open and editable, and more than 20 process packages are all provided free of charge, which provides great convenience for customer product process development, while constantly updating high-efficiency processes, such as 60-micron titanium alloy entities and The porous structure process can ensure that customers have always been in a leading position in product production costs.

More and more SLM Solutions customers have obtained FDA and CE certifications for 3D printing products, and more and more successful clinical cases have been accumulated. For example, in the application of customized implants, Australia ’s first metal 3D printed spinal implant clinical case was supported by Royal Melbourne Institute of Technology (RMIT). RMIT used SLM Solutions equipment to complete the printing of titanium alloy implants. And successfully implanted, successfully cured the patient's spine pain. Not only is the spinal implant, RMIT also helps tumor patients to custom print the heel bone to replace the heel bone tissue removed at the tumor site to relieve the patient's pain.

In addition to clinical cases, SLM Solutions also has outstanding performance in the mass production of medical devices. Regardless of the structural design of the device or the development of process parameters, SLM Solutions is all pursuing printing efficiency while ensuring product quality.

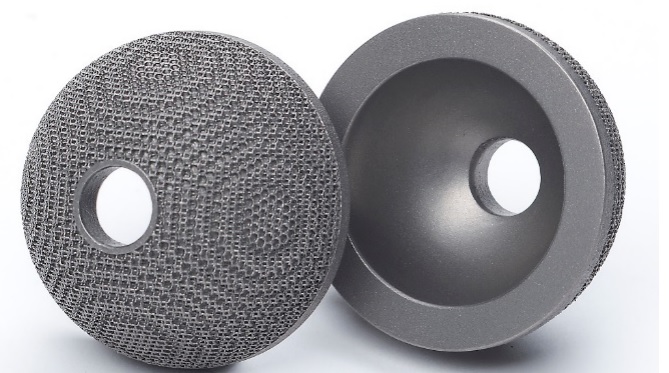

Acetabular cups and interbody fusion cages are the key mass production areas for medical metal 3D printing. SLM Solutions has conducted a lot of research and exploration on these two types of products. , And can achieve unsupported printing inside the acetabular cup, greatly reducing the workload of medical customers post-processing. In the field of knee joint applications, SLM Solutions continues to develop a 60-micron parametric cobalt-chromium alloy process on the basis of a 30-micron mature process, leading the industry with absolute advantages. SLM Solutions has developed multi-laser technology since 2011 and has nearly ten years of experience in use and verification. Multi-laser technology makes the printing efficiency of laser metal 3D printing equipment increase by multiples, which solves the problems of low efficiency and high cost of single laser printing.

60 micron thick titanium alloy printing acetabular cup implant, double laser acetabular cup full-page printing

Cobalt-chromium alloy knee implant

According to the "Wohlers Report 2020" recently released by Wohlers Associates, the additive manufacturing industry has started 10 years of growth since 2009. The average growth rate in the past 4 years (2016-2019) has reached 23.3%, and it will continue to grow substantially in the future. Wohlers Associates expects global sales of additive manufacturing-related products and services to reach $ 117.5 billion in 2029.

Such a huge market space, the introduction of high-quality 3D printed medical devices, will inevitably bring rich market revenue and valuable development opportunities for related companies. SLM Solutions ’technical team received positive feedback from customers. Ma Jianli said,“ As ZJKH ’s slogan 'Technology serves health', China's medical device companies are extremely determined to improve their technological innovation capabilities. The attitude of foreign cooperation is open and positive. Therefore, I am very confident in the application of SLM Solutions in the medical field. We have every reason to believe that through our close cooperation with various parties, major domestic medical institutions can use it in the future. It is not a distant dream for advanced domestic medical devices that every household can use inexpensive and high-quality domestic medical devices.