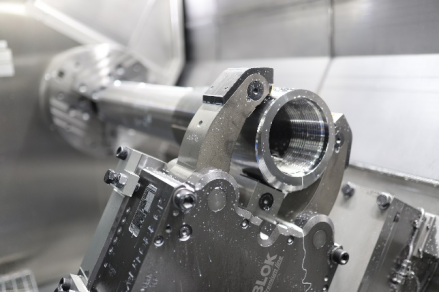

Precision machining capability [deep holes, eccentricity]

·The company has obtained the API Q1-3702 qualification certificate, obtained thread processing qualifications from multiple customers, and has rich experience in thread processing and software and hardware facilities;

·The company specializes in the processing of high-precision machining parts for shafts within 3 meters;

·Deep blind hole processing with a length to diameter ratio of 40 times;

·Suitable for processing various high-precision, special materials, eccentric internal shapes, elbows, and complex geometric parts.

.Machinable complex structural parts such as long shaft sleeves with a diameter ≤ 400mm and a length ≤ 3000mm

Reference Products

Logging cable casing

Hydraulic pump components for ship equipment

The major long axis

The materials that we often precision machining:

·Carbon and carbon steel: 45 #, 20 #, 1020

·Alloy steel: 4140/4145, 4330V, 4340

·Alloy tool steel: D2, S7

·Mold steel: H13

·Austenitic stainless steel: 316L, 304, UNS31803

·Martensite stainless steel: 17-4PH, 410, 420

·Duplex stainless steel: 2205

·High temperature alloys: Inconel718, 625, 725, 925, etc

·Non magnetic steel: P550

·Titanium alloy: TC4, TC11, TA6

·Copper, aluminum