On May 30, 2020, the 2019 ZJ Patent Awards ceremony was held in Shanghai, and 44 patents were awarded. Among them, NBJF Electronic Materials Technology Group won the gold prize of scientific and technological innovation patent for its invention patent "A method of manufacturing a tantalum target".

NBJF's self-developed "a method of manufacturing tantalum targets" has filled the gap in the manufacture of tantalum targets in China and achieved a major breakthrough in the field of semiconductor materials.

Tantalum target, also known as sputtering target, is a key material for manufacturing metal wires on chips. Currently, there are only four companies in three countries in the world.

"From a micro perspective, the orientation of each metal atom on the sputtering target will have a decisive influence on the quality of the metal interconnection lines in the chip." NBJF chief engineer Wang Xueze told reporters.

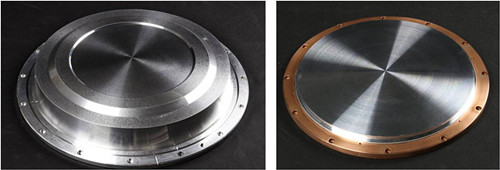

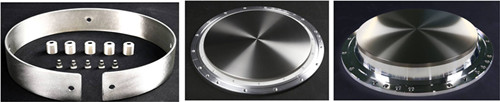

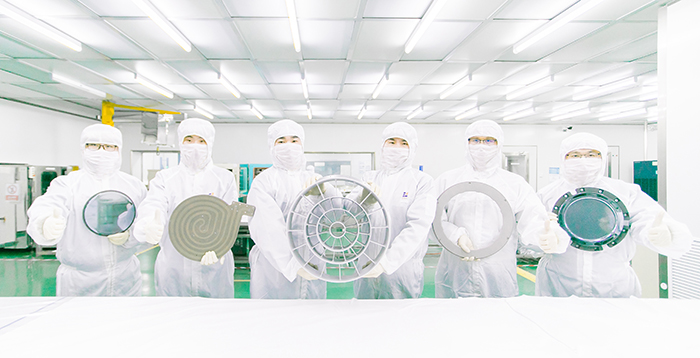

NBJF is engaged in the research, development, production and sales of high-purity sputtering targets. Its main products are various high-purity sputtering targets, including aluminum targets, titanium targets, tantalum targets, tungsten-titanium targets, etc. These products are mainly used in semiconductors ( Mainly in the field of very large scale integrated circuits), flat panel display, solar energy and other fields.

The high-purity sputtering target industry has the dual characteristics of technology-intensive and capital-intensive, huge investment in production equipment, rich product technology content, high requirements for production processes and technical capabilities, the need to establish a professional technical team and possess deeper technology reserve. NBJF is a typical entrepreneurial enterprise initiated by a technical team. Under the leadership of a stable core management team, with leading technological advantages and reliable product quality, the company has achieved a more favorable market position in the industry and established a strong Competitive advantage.

In recent years, NBJF has continued to attach importance to technological innovation, increased R&D efforts, and established the "National High-Purity Target Engineering (Technology) Center" and "National Demonstration Expert Workstation" to provide a strong guarantee for the innovation and advanced technology of its products . As of December 31, 2019, NBJF Corporation and its subsidiaries had obtained 264 mainland authorized patents, including 217 invention patents and 47 utility models. In addition, the company obtained 2 invention patents in South Korea and 1 invention patent in Taiwan. The above patents cover a series of production processes such as metal purification, grain orientation control, welding technology, precision machining, cleaning and packaging.

In 2015, the company was rated as "National Intellectual Property Advantage Enterprise" by the State Intellectual Property Office, and won the "First Prize of Scientific and Technological Innovation Technology Invention" honor. In 2019, the company's patents ranked 74th in the "Top 500 Chinese Enterprise Patent List". Relying on the leading technical strength and high-level technical team, the company has undertaken or presided over a number of national research projects such as "863 Program Key Project", "863 Program Guide Project", "02 Special Project" and so on.

Ultra-high purity metals and sputtering targets are one of the key materials for the production of ultra-large-scale integrated circuits, and their preparation technology is mainly monopolized by a few companies in Japan and the United States. NBJF focuses on innovation and breaks the situation of foreign giants monopolizing high-end sputtering targets for semiconductors. The company has now mastered the core technology in the production of high-purity metals and sputtering targets. The most advanced manufacturing process applied to world-famous semiconductor manufacturers has achieved mass supply at the 7nm technology node, and products have been exported to more than 280 semiconductor chip manufacturing plants worldwide. At present, 5nm technology node target samples are being verified on the client side.

About NBJF Electronic Materials Technology Group

NBJF Electronic Materials Technology Group is a high-tech company founded in 2005 by a group of highly-educated oversea returnees and foreign experts.

NBJF is specialized in developing and manufacturing ultra-high purity metal materials and sputtering targets for the semiconductor and integrated circuit industries.

The company has been acknowledged and respected by the semiconductor manufacturers world widely. The sales network covers Europe, North America and Asia. After ten years development, NBJF has various options of target materials, including but not limited to Al, Ti, Ta, Cu Si , Nb, Cr and diversified alloys.

Products

Semiconductor Targets

High Purity Aluminum & Aluminum Alloy Targets

Materials: Al, Al30ppmSi, Al0.5Si, Al0.75Si, Al0.8Si, Al1Si, Al0.5Cu and AlSiCu etc.

Purity: 4N ~ 5N5 (99.99% ~ 99.9995%)

Grain Size and Orientation: Upon Customer`s Demands

Highlight: Various customized long life targets available

High Purity Titanium Targets and Coils

Purity: 4N5 ~ 5N (99.995% ~ 99.999%), Low oxygen Titanium

Grain Size and Orientation: Upon Customer ’s Demands

Highlight: Various customized long life targets and coils available

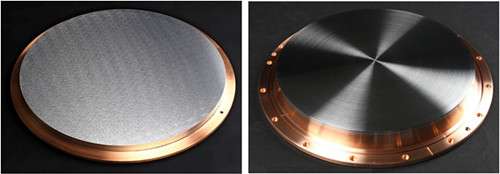

High Purity Cu and Cu Alloy Targets, Cu coils and Cu Anode

Purity: 4N (99.99%), 4N5 (99.995%), 5N (99.999%), 6N (99.9999%) and CuAl alloy

High purity Cu Anode and CuP Anode

High purity Cu coil

Grain Size and Orientation: Upon Customer`s Demands

Highlight: Various customized long life targets and Anode materials

High Purity Tantalum and Tantalum Alloy Targets and Tantalum Coils

Ta target and coil Purity: 3N ~ 5N (99.9% ~ 99.999%)

Grain Size and Orientation: Upon Customer`s Demands

Highlight: Various customized long life targets and coils available

Coil refurbish services are available for the most effective cost saving for our customers.

All kinds of special metal sputtering targets, including:

High purity W, Ti-W, Ni, Ni alloy, Cr and Coetc.

Solar Targets

NBJF has advantage on specialized in R & D and, manufacturing and sales of all kinds of high purity metal sputtering targets and backing plates for the Solar industry.

It products include high purity Al & Cu targets, powder metallurgy targets such as WTi, NiV, Cr and Mo etc. as well as Cu backing plate and Cu antenna.

Purity: 3N ~ 6N (99.9% ~ 99.9999%)

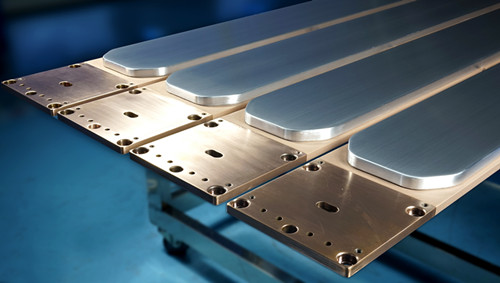

LCD Targets

High purity Al, Cu Mo targets for G4.5, G5, G5.5, G6 and G8.5

NBJF is the first company in China to manufacture and sell all types of high purity metal sputtering target and spare parts for the large screen Liquid Crystal Display. We provide the market with various targets for different generations (G4.5 – G8.5), dimensions (T16 & T18 etc.) and materials (Al, Cu & Mo) with strong R & D capability, technical support and advanced production management system. KFMI targets have been applied to all leading TFT-LCD fabs, and it can be compliant with strict requirements from different customers on dimension, grain size and appearances.

Shield plate for PVD and liquid crystal glass handing parts for CFRP

High-strength Carbon Fiber Reinforced Plastics has advantage of light weight, high strength and good abrasion resistance. it is the only qualified Chinese manufacturer supplying CFRP robot arm for large glass transmission. With support of our strong machining capability, KFMI is now in mass production for all kinds of PVD parts, such as shield plate, at the mainstream LCD fabs.

TF Products

It has ability on R & D, manufacture and selling all kinds of precision parts for semi conductor:

Clamp Ring & Collimator for PVD tools

Face plate, Shower head for CVD and Etching tools

Diamond Disk and Retainer Ring for CMP tool

High-Purity Materials

Raw Material Introduction

High-Purity Cu (Purity: 99.99%)

No hydrogen embrittlement, High conductivity, Good properties in processing / welding / corrosion resistance and cryogenic temperature

Mainly applicable toused for sputtering target, anode, solar product, audio device, vacuum electron device and cable etc.

High-Purity Al (Purity: 99.999%)

Low deformation resistance, high conductivity and good plasticity

Widely applicable to scientific research, electronic industry, chemical industry, and used to manufacture high-purity alloy, laser materials targets and other special applications

Round ingot and square shape ingots are both available base on customer`s demands.

It has been equipped with all necessary manufacturing and testing devices for target manufacturing in house. This ensures our high capacity, short lead time, and more importantly cutting edge quality control and extremely quick response for customer inquiries.

Since the first day of the company, NBJF has continuously earned significant support from Ministry of Science and Technology (“MOST”), National Development and Reform Commission (“NDRC”), and Ministry of Industry and Information Technology (“MIIT”) of China. KFMI has participated and led several national level research and industrialization projects, including Chinese National 02 Special Project, National 863 Special Project, High-tech Industrialization Project (supported by NDRC), National fund of Electronic Industry Development (supported by MIIT).

NBJF products have been honored the “Outstanding Contribution Award in the Chinese National Key Technology Projects in the Eleventh-Five-Years Period”, the “Creative New Product and Technology in Semiconductor Award of China”, the “Strategic Innovative Product Award of China” (issued by MOST), the “First-class Nonferrous Metals Industry Science and Technology Award of China”, “First Prize of Provincial Technological Invention Award”, and the “First-class Scientific and Technological Progress Award”.